When it comes to maintaining your outdoor equipment, having a clear understanding of each component and its function is essential for effective repairs. Every machine is made up of numerous parts that work together to deliver optimal performance. Knowing how to identify and replace these parts can significantly extend the life of your tools and prevent unexpected breakdowns.

Accurate identification of broken or worn-out pieces is key to ensuring smooth operations and avoiding unnecessary damage. Proper maintenance also involves knowing how each element fits together and how they interact with one another. By familiarizing yourself with the machine’s structure, you gain the confidence to make repairs independently and efficiently.

With the right knowledge, keeping your equipment in top shape becomes a much easier task. Whether you’re a professional or a hobbyist, understanding how to manage repairs and replacements will save time and money in the long run.

Understanding Husqvarna 372 XP Components

Every tool is composed of multiple elements that must work in harmony to ensure efficient performance. Each component plays a specific role, contributing to the overall functioning of the machine. Gaining a clear understanding of how these components interact is crucial for anyone involved in maintaining or repairing the equipment.

By familiarizing yourself with the key parts, you can easily identify potential issues and address them promptly. Knowing the function of each individual piece allows you to take proactive measures, ensuring the longevity and reliability of your tool. Whether you’re replacing a worn-out component or performing routine maintenance, understanding the internal structure is the foundation of proper care.

In this section, we’ll take a closer look at the essential components that make up the machinery, exploring their specific roles and how they contribute to the overall operation. This knowledge will help you make more informed decisions when it comes to troubleshooting and repairs, keeping your tool running smoothly for years to come.

How to Use the Parts Diagram Effectively

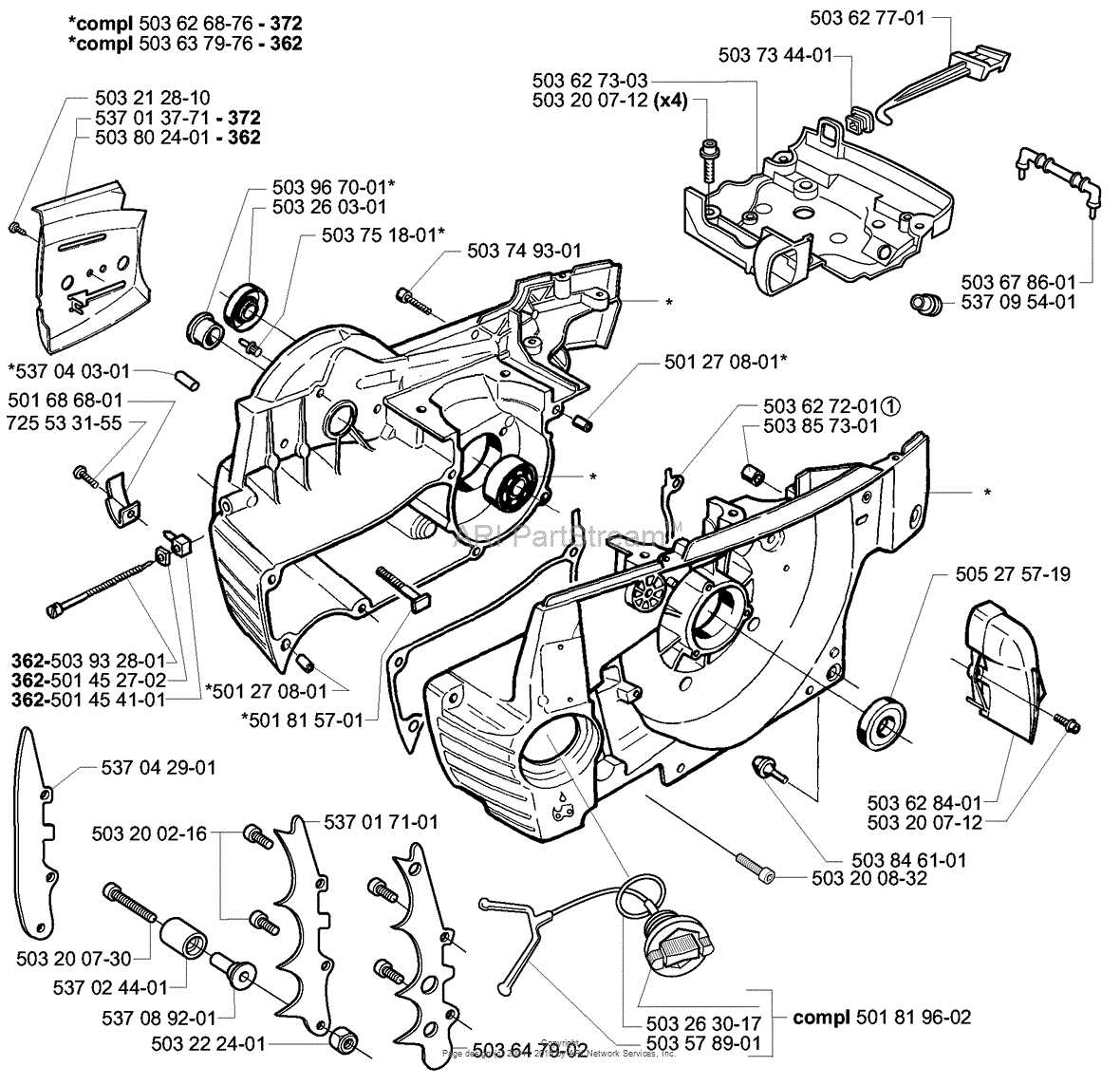

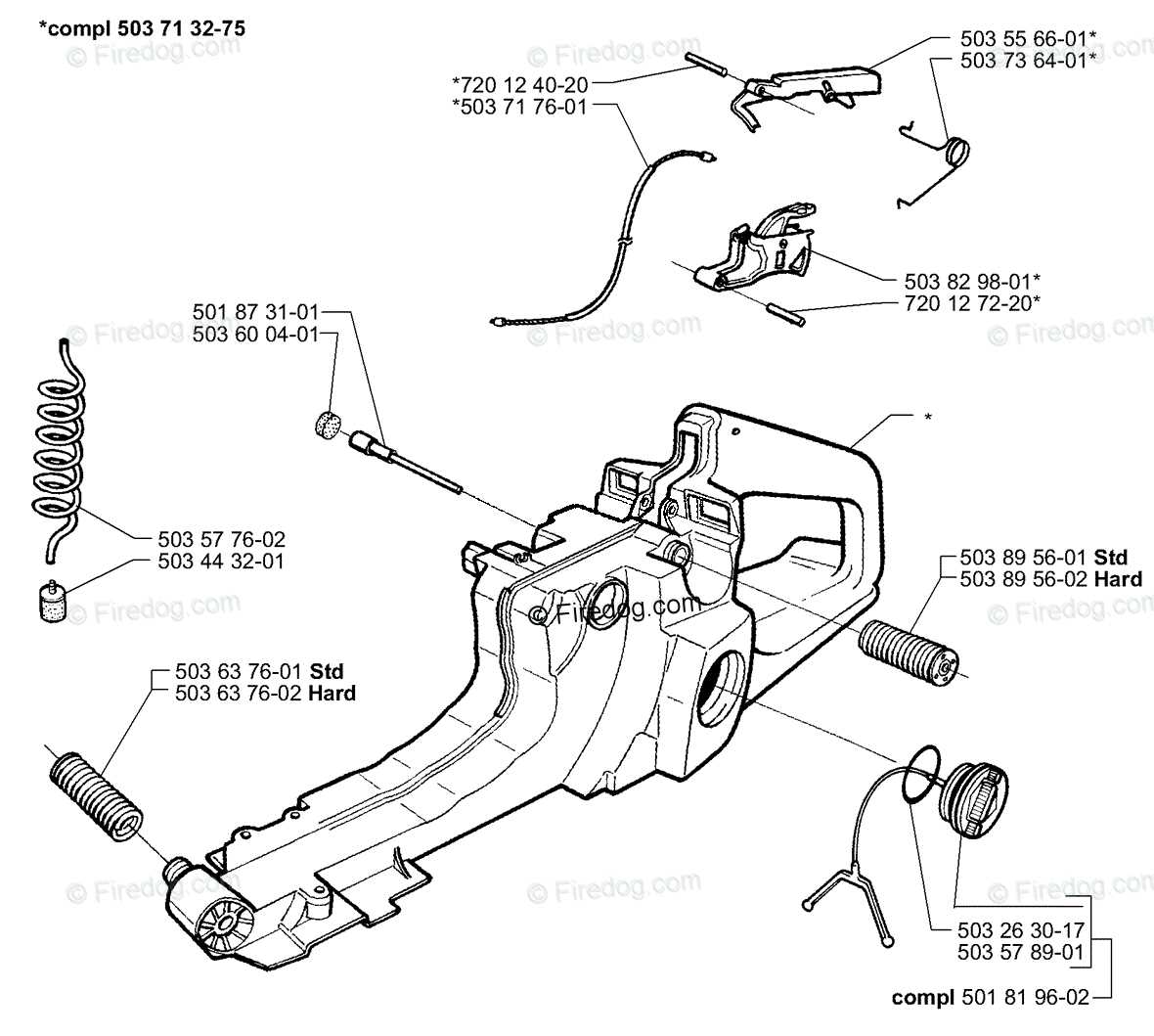

Understanding the layout and structure of your tool’s components is essential for efficient repairs. A clear visual representation can simplify the process of identifying, ordering, and replacing individual pieces. By referring to a well-organized chart, you can gain a comprehensive understanding of how everything fits together and functions as a whole.

Identifying Components and Their Functions

The first step in using the visual guide effectively is to familiarize yourself with the key components. Each section of the illustration typically shows the parts in their correct orientation and arrangement. Knowing where each element belongs within the machine allows you to quickly spot the specific parts you need to replace or inspect.

Using the Visual Guide for Troubleshooting

Another benefit of a detailed illustration is its ability to assist with troubleshooting. If your tool is experiencing issues, the visual guide can help you pinpoint the likely cause by showing you which components interact with one another. By isolating the malfunctioning part, you can focus your repair efforts more precisely, saving both time and effort.

Common Issues and Part Replacements for 372 XP

Over time, even the most durable tools can experience wear and tear, leading to malfunctions or reduced performance. Understanding the most common issues that arise in such machines is key to preventing extended downtime and costly repairs. Regular maintenance and timely part replacements can keep your equipment running smoothly and efficiently.

One frequent issue is the failure of the ignition system. If the engine fails to start or runs intermittently, it may be due to a faulty spark plug or ignition coil. Replacing these components can restore reliable operation. Another common problem involves the fuel system, particularly clogged fuel filters or fuel lines, which can hinder engine performance and fuel efficiency. Replacing these parts ensures a smooth flow of fuel to the engine, preventing stalling or poor operation.

Additionally, wear on the chain and bar is a natural occurrence with frequent use. A dull or damaged chain can reduce cutting efficiency and cause strain on the engine. Regularly replacing the chain and bar when they show signs of wear ensures the tool performs at its best. Identifying these common issues early and addressing them with timely replacements will extend the life of your machine and maintain its peak performance.