Maintaining outdoor machinery can be challenging without a clear understanding of its internal elements. Knowing each part’s function ensures that repairs are more efficient and replacements are made with precision. Having a clear reference to each component helps identify issues early, saving both time and money.

To keep your equipment running smoothly, it’s essential to familiarize yourself with its individual elements. A well-detailed reference guide provides insight into how different parts fit together, making it easier to troubleshoot and maintain the machine. This approach also minimizes the risk of overlooking small yet important details during routine inspections or repairs.

With the right information, you can confidently perform maintenance tasks, ensuring your machinery operates at its best throughout the season. A thorough understanding of the system’s layout will also help you quickly identify worn-out or broken components that need attention.

Understanding the Husqvarna Snow Thrower Parts

Every outdoor equipment consists of various crucial components that work together to ensure efficient operation. Understanding the layout of these elements not only helps in recognizing their functions but also makes it easier to perform repairs and replacements. With a clear knowledge of the different parts, troubleshooting becomes more straightforward, and you can quickly address any issues that arise during usage.

Key Components and Their Functions

The main structure of your machine relies on several key components that enable its overall performance. Each element plays a specific role, whether it’s in driving the mechanism, handling the movement, or ensuring the safety and functionality of the equipment. A solid grasp of each part’s function allows you to assess its condition effectively and identify any parts that might need maintenance or replacement.

Common Signs of Wear and Tear

Over time, regular use can lead to the natural wear and tear of specific parts. Identifying these signs early can prevent further damage and costly repairs. Components such as the drive system or the operational mechanisms may show visible signs of damage or wear. Understanding where these issues typically occur helps in the proactive maintenance of the equipment.

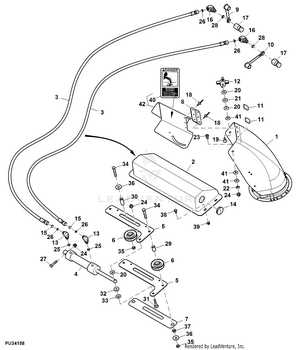

How to Use the Parts Diagram Effectively

Having a visual reference for your equipment’s internal structure is invaluable for both maintenance and repair tasks. A detailed visual guide helps you understand the layout of the different components, making it easier to identify where each part fits within the machine. By using this reference, you can efficiently pinpoint specific areas that require attention, ensuring more accurate repairs and replacements.

Step-by-Step Approach to Reading the Visual Guide

Start by familiarizing yourself with the entire system. Identify the main parts and their connections to each other. Focus on the labels or numbered sections that correspond to specific components. By tracing each part’s function, you can better understand how they interact and the role they play in the overall operation. This will also help you spot potential issues quickly.

Practical Tips for Quick Repairs

When facing an issue with your equipment, refer to the guide to locate the problematic area. Once you identify the part in question, check for wear, damage, or other irregularities. Knowing the correct terminology and structure will assist you in ordering the right replacement parts and performing repairs without unnecessary delays.

Common Issues and Part Replacements

As with any mechanical device, regular use can lead to certain common issues that require attention. Identifying these problems early is essential to prevent more significant damage. Many of these issues are related to wear and tear of specific components, which, if not addressed, can affect the overall performance of the equipment.

Frequent Problems and Their Causes

One of the most common issues is difficulty with the drive mechanism, often caused by worn belts or damaged gears. Another typical problem is malfunctioning blades or augers, which can become clogged or lose effectiveness due to prolonged use. Additionally, the engine might experience starting issues, typically linked to faulty spark plugs or fuel system components. Recognizing these signs early can help avoid further damage and reduce repair costs.

When to Replace Components

If a part is excessively worn or damaged, replacement is the most practical solution. For example, belts and gears should be replaced if they show signs of cracking or slipping. Blades and augers should be changed when they are no longer sharp or have visible signs of corrosion. Replacing faulty components as soon as issues arise ensures that your equipment continues to function properly and extends its lifespan.