Every intricate tool, whether for crafting or repairing, consists of several key elements that work together in harmony. Understanding how these individual components function can make all the difference in maintaining and optimizing your gear. This knowledge empowers users to handle basic issues with confidence and ensures longevity for their tools.

In this guide, we will explore how to identify and understand the various components that make up your device. By learning how each piece interacts, you can gain better control over maintenance tasks, troubleshoot effectively, and even perform simple repairs without professional help.

Mastering the internal structure of your gear will not only enhance your efficiency but also reduce the risk of costly repairs. With this detailed overview, you’ll be equipped to make informed decisions and keep your tool in peak condition for years to come.

Understanding the Components of Singer Machines

Each device used for fabric manipulation relies on a variety of mechanisms to function smoothly. These internal elements work together to perform specific tasks, and understanding how they fit into the overall structure is key to efficient operation. Knowing the role of each part helps identify issues early and allows for proper care and maintenance.

The core components of your equipment include a range of moving and stationary elements, each contributing to the tool’s effectiveness. From the base to the upper assembly, these pieces play specific roles that enable smooth operation. Learning how they interact with one another will deepen your understanding and improve your troubleshooting skills.

Regular maintenance, such as cleaning and proper lubrication, is essential to keep all the parts functioning as intended. A well-maintained system can perform at its peak for years, providing reliable results and minimizing the risk of unexpected breakdowns. Identifying each element in the structure can guide you in taking proactive steps for care and repairs.

How to Identify Parts on Singer Machines

Recognizing the components within your equipment is essential for troubleshooting and effective maintenance. Understanding the location and function of each part allows you to pinpoint potential issues quickly and accurately. This knowledge can save time and prevent unnecessary repairs, empowering you to take control of your device’s upkeep.

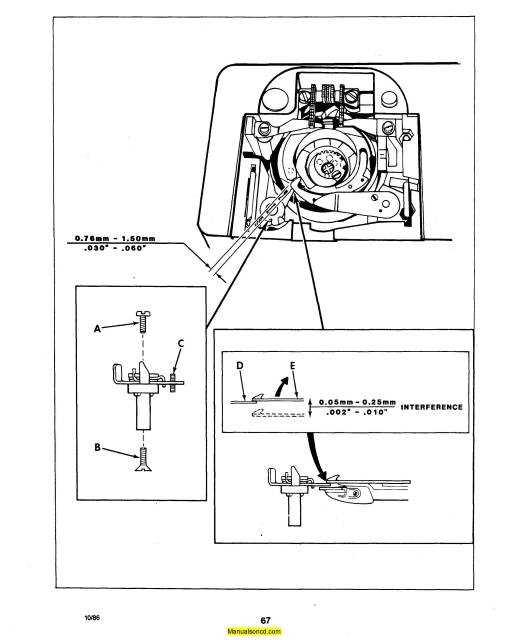

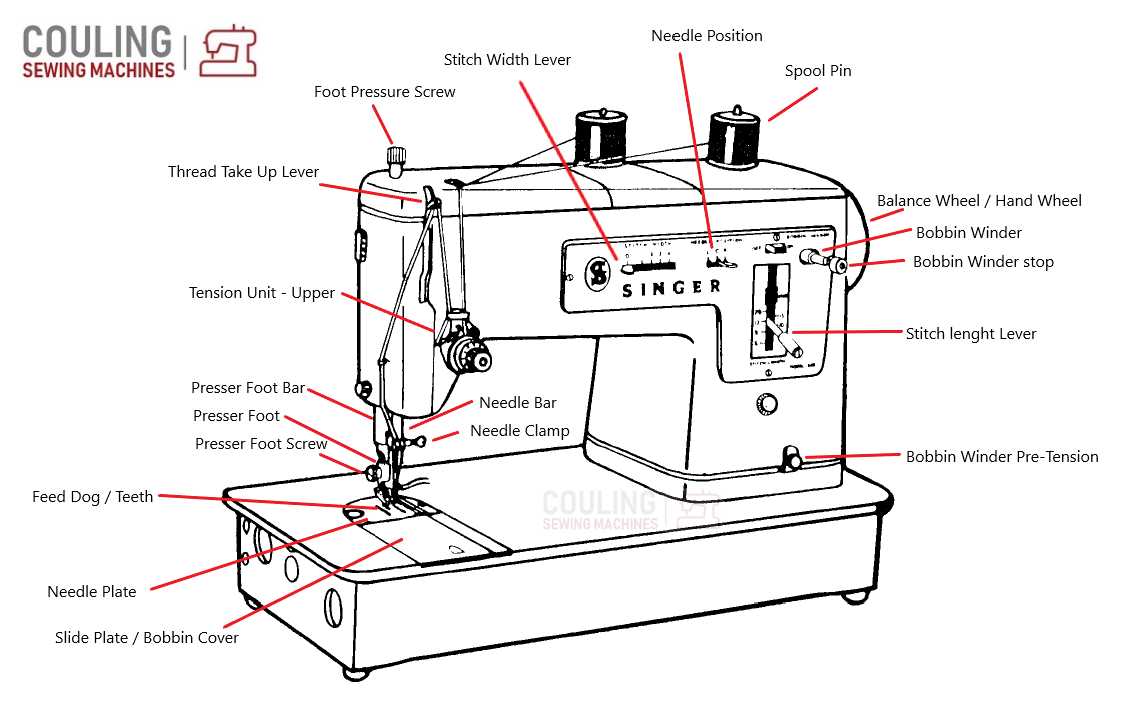

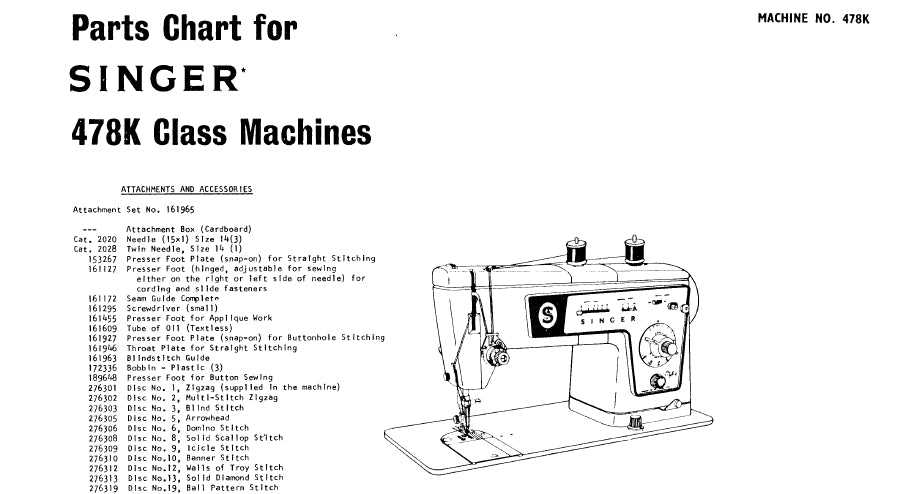

Start by familiarizing yourself with the external elements of your tool. These are usually easy to spot and include handles, knobs, and foot pedals. Once you’re comfortable with the external layout, move to the internal components, such as the drive mechanisms, gears, and belts. Each part is designed to work in tandem, so learning their roles will help you detect irregularities during operation.

Using a reference guide or a clear visual representation can further assist in identifying the parts accurately. By regularly examining the tool’s inner and outer components, you can maintain a clearer understanding of how everything functions, ensuring better overall performance.

Common Issues and Repair Tips for Parts

Over time, certain issues may arise in your tool that could affect its performance. Recognizing these problems early allows for quicker fixes, preventing further damage and extending the life of your device. Most common issues stem from wear and tear, misalignment, or lack of maintenance.

Unusual Noises and Vibrations

One of the most common signs of trouble is the presence of strange noises or excessive vibration during operation. These sounds may indicate that components are loose, misaligned, or not properly lubricated. Inspect the internal mechanisms for any worn-out parts or debris. Regularly lubricating moving elements can reduce friction and prevent premature damage.

Difficulty in Movement or Sticking Parts

If certain parts become stiff or difficult to move, it may be due to dirt buildup, lack of lubrication, or corrosion. Cleaning and applying appropriate lubricants to the affected components can help restore smooth function. Always check that the gears and other moving elements are aligned and free from any obstructions to ensure seamless performance.

Tip: Always follow the manufacturer’s guidelines for maintenance and repairs. Taking preventive measures like regular cleaning and lubricating will reduce the likelihood of serious issues developing.