When working with tractors, understanding the different connection systems is essential for efficient use and maintenance. These systems are designed to link various implements to the tractor, enabling it to perform a wide range of tasks. A detailed breakdown of these systems can help users ensure proper functionality and address any issues that may arise over time.

Each part plays a specific role in securing and controlling attached equipment, which is why having a clear understanding of the components is crucial. Visual guides and breakdowns of these systems offer valuable insights, helping users identify and troubleshoot problems quickly. Proper maintenance and repair can extend the lifespan of both the tractor and its attachments.

In this article, we will explore how these connection systems work, how to interpret related technical guides, and the common challenges that might arise with their use. Whether you’re a seasoned farmer or a novice operator, understanding these essentials will ensure smoother operations and better overall performance.

Understanding Tractor Attachment Connection Components

Tractors are equipped with a variety of connection systems that allow the attachment of different implements for a wide range of tasks. These systems are essential for proper functionality, ensuring secure attachment and control of equipment. By familiarizing yourself with these components, you can improve both the efficiency and safety of your machinery.

Key Components of the Tractor Connection System

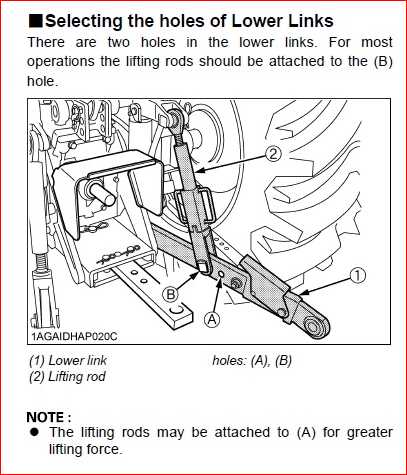

The primary components of the connection system include the lift arms, lower links, and control mechanisms. The lift arms are responsible for raising and lowering attached implements, while the lower links provide the necessary support and stabilization. The control system helps adjust the tension and movement of these components, ensuring smooth operation during use.

Importance of Proper Maintenance

Understanding each component’s role is crucial for maintaining optimal performance. Regular inspection and maintenance of these parts help prevent breakdowns and extend the lifespan of both the tractor and its attachments. Identifying and addressing issues early can save time, reduce costs, and improve overall efficiency in the long run.

How to Read a Tractor Attachment Connection Guide

Understanding how to interpret a technical guide for the tractor connection system is essential for effective troubleshooting and maintenance. These guides provide a visual representation of the components and their interconnections, making it easier to identify issues and carry out repairs. A proper understanding of the schematic will allow operators to quickly locate and address any malfunctioning or worn-out parts.

Interpreting Symbols and Labels

One of the key elements of a technical guide is the use of symbols and labels to represent various components. These symbols are standardized, allowing users to quickly recognize parts such as lift arms, lower links, and control mechanisms. Labels next to each symbol often provide further details, such as part numbers or specifications, which are crucial for accurate replacements and repairs.

Following the Flow of Connections

Another critical aspect of reading the guide is understanding the flow of connections. The diagram will typically show how each part is linked to another, demonstrating the sequence of operations. This can help identify potential issues caused by loose connections or damaged links, making it easier to pinpoint the source of a problem and ensure proper functionality during operation.

Common Issues with Tractor Attachment Components

While tractor attachment systems are designed for durability, certain components are prone to wear and tear over time. These issues can impact the efficiency and safety of the machine. Recognizing the most common problems early on can save time and money, as well as ensure smooth operation during tasks.

Worn or Loose Connections

One of the most frequent issues in tractor connection systems is worn or loose connections between the various components. Over time, the stress of frequent use can cause bolts, pins, and links to loosen, leading to unstable attachments. This can result in reduced control over the equipment, and in severe cases, lead to damage. Regularly checking and tightening these connections is crucial for maintaining performance.

Corrosion and Rust Damage

Another common issue is corrosion caused by prolonged exposure to moisture, dirt, and harsh weather conditions. Rust can quickly degrade the strength of the connection system, leading to potential breakage. To prevent this, it’s essential to clean and lubricate parts regularly and check for any signs of rust. If rust is detected, it should be addressed immediately to avoid further damage.