For anyone maintaining or repairing agricultural machinery, having a clear understanding of the different components is essential. This knowledge allows for more efficient troubleshooting and part replacement, ensuring optimal performance of the equipment. Proper identification of each part simplifies the process of fixing any issues that arise.

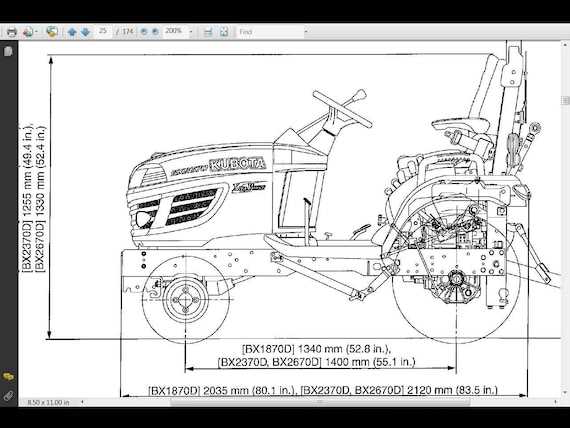

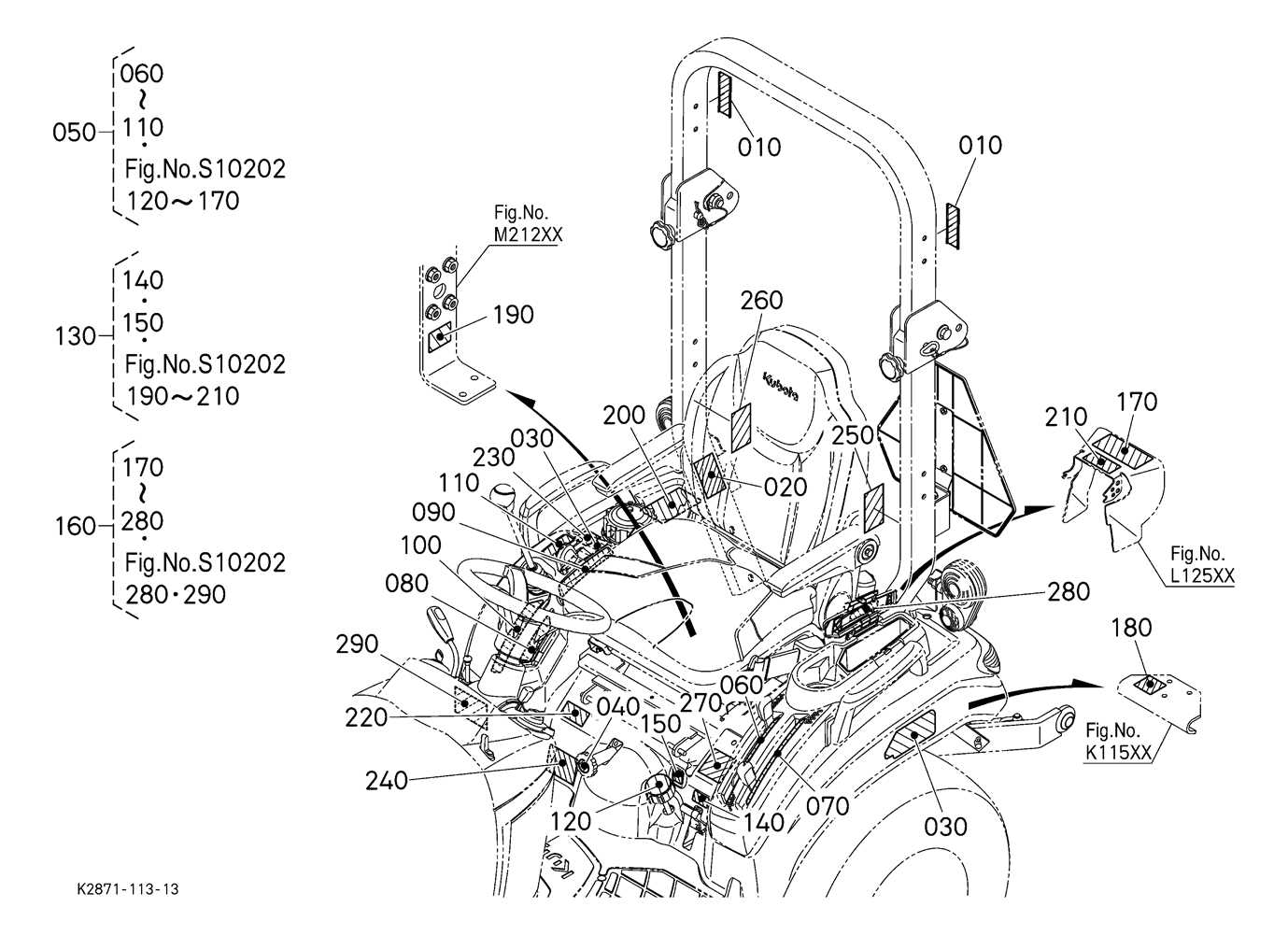

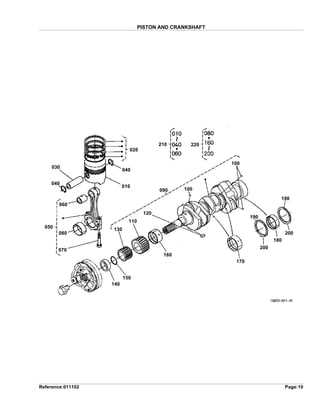

Detailed illustrations and diagrams serve as a valuable tool for users who are unfamiliar with the inner workings of their machinery. These visuals not only show the arrangement of each component but also highlight their connections, making it easier to understand how the system functions as a whole.

In this guide, we’ll break down the essential elements of machinery layouts, offering insights on how to interpret these helpful diagrams and effectively manage repairs. Whether you’re a seasoned operator or a first-time user, learning how to read these detailed layouts will significantly enhance your repair experience.

Tractor Component Overview

Understanding the different components of a tractor is crucial for anyone looking to perform maintenance or repairs. These machines are made up of various systems and parts, each serving a specific function to ensure the smooth operation of the entire vehicle. Identifying these parts and knowing their purpose can significantly reduce repair time and improve overall efficiency.

Essential Mechanical Systems

Tractors consist of several key mechanical systems, including the engine, transmission, and hydraulic system. Each of these systems plays a vital role in powering the machine and enabling it to perform tasks like plowing, hauling, or mowing. Understanding how these systems interact with one another helps users make informed decisions when it comes to maintenance and troubleshooting.

Structural and Electrical Components

In addition to mechanical systems, tractors also feature a range of structural and electrical components. These include the chassis, steering, electrical wiring, and control systems. Proper care and attention to these parts ensure that the tractor remains functional and responsive to user inputs, extending its lifespan and improving its operational reliability.

Understanding the Components of the Tractor

Familiarizing oneself with the various elements of a tractor is essential for anyone involved in maintenance or repair tasks. Each component has a specific role that contributes to the overall function of the machine. By understanding how these individual parts work together, users can effectively address any issues and maintain the machine’s performance.

Mechanical systems such as the engine, transmission, and hydraulic components form the backbone of the tractor’s operation. These systems work in unison to power the machine, enabling it to perform heavy-duty tasks like lifting, towing, and digging. Without a proper understanding of how these systems function, diagnosing and fixing issues becomes significantly more challenging.

Structural components, including the frame and steering, provide the stability and maneuverability needed for safe and efficient operation. Electrical systems also play a crucial role, powering features like lights, controls, and monitoring systems. A good grasp of each of these elements ensures that the tractor remains in optimal working condition for years to come.

How to Read the Components Layout

Interpreting a layout of machine components is an essential skill for anyone working with equipment. These visuals provide detailed information about how each element is positioned and connected, offering a comprehensive view of the system. By understanding these layouts, users can quickly identify the components that need attention during maintenance or repair tasks.

Key Symbols and Labels

The first step in reading these layouts is to understand the symbols and labels used. Each component is typically represented by a simple drawing or icon, with numbers or letters indicating specific parts. These markings provide a clear reference for finding and replacing individual elements.

Using the Layout for Maintenance

Once you understand the symbols, you can use the layout as a guide during repairs. It helps identify which parts are connected, which are removable, and which need to be checked for wear or damage. This ensures a more organized and efficient approach to maintenance.

| Symbol | Description |

|---|---|

| Circle | Represents a mechanical component, such as a gear or valve |

| Square | Indicates electrical components, such as wires or sensors |

| Arrow | Shows the flow of fluid or energy within the system |

Step-by-Step Guide to Identifying Components

Identifying the various elements of a machine is an important step in performing maintenance and repairs. By understanding the structure and function of each component, you can more effectively address issues and ensure the equipment is running smoothly. This guide will walk you through the process of recognizing and locating the components that make up the system.

Gather the Necessary Tools

Before you start identifying the components, make sure you have the following tools:

- Clear image or layout of the system

- Owner’s manual or technical documentation

- Labeling tools (if needed, for organizing components)

Follow These Steps

To accurately identify each component, follow these steps:

- Examine the layout carefully to familiarize yourself with the general arrangement of the machine.

- Locate the larger mechanical systems first, such as the engine or hydraulic components, to get an overview of the setup.

- Identify smaller parts by looking for detailed icons or numbers that correspond to specific elements in the system.

- Cross-reference the numbers or symbols with your manual to confirm each component’s exact location and function.

- Label or note any parts that require attention, repair, or replacement.

By following these steps, you’ll be able to accurately identify the components within your equipment, making the repair or maintenance process much more efficient.

Common Issues and Part Replacements

When maintaining machinery, it’s important to be aware of the most common issues that can arise and how to address them. Many problems are caused by wear and tear on specific components, while others may result from improper use or lack of regular maintenance. Understanding these common problems and knowing how to replace the affected parts can help keep the machine running smoothly.

Mechanical failures such as engine malfunctions or transmission issues are among the most common problems. These typically require the replacement of worn or damaged components, such as belts, seals, or gears. Regular inspection can help identify these issues before they lead to more significant damage.

Hydraulic system problems are another frequent cause of machine downtime. Leaks or low fluid levels can impair the performance of hydraulic systems. Replacing seals, hoses, or filters as part of routine maintenance can prevent these issues from escalating.

Electrical problems, such as faulty wiring or malfunctioning sensors, are also common. Regularly checking the electrical components and replacing damaged parts ensures that the machine’s control systems function properly, avoiding unexpected shutdowns.