When it comes to maintaining and repairing machinery, having a clear visual representation of its internal structure can be invaluable. Knowing where each part fits and how they interact can save both time and effort during maintenance or troubleshooting. A well-organized guide provides essential information for quick identification and proper care of equipment.

For anyone who works with agricultural machinery, a reliable reference is crucial. This guide will help you navigate through complex systems, making it easier to address any issues that arise. Whether you are a seasoned mechanic or a first-time user, understanding the layout of different components will improve your ability to perform repairs efficiently.

Accurate identification of each element allows for effective maintenance and minimizes the risk of mistakes. By breaking down the machinery into manageable sections, it becomes less overwhelming to approach repairs and adjustments. With a focus on precision and clarity, this guide ensures you have the necessary resources to handle your tasks with confidence.

Understanding Tractor Component Layout

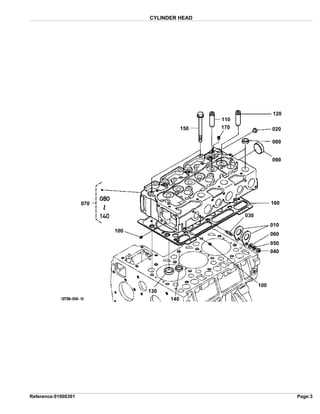

Having a clear understanding of the internal configuration of your machinery is crucial for performing accurate maintenance and repairs. This knowledge helps identify individual elements, their positions, and their functions within the overall system. By referring to an organized visual guide, you can easily determine which parts need attention and where they fit within the machinery.

The primary goal of such a layout is to provide a comprehensive overview of all essential components, allowing for efficient troubleshooting and precise replacements. It breaks down the complex system into simple sections, making the process less daunting. This approach also aids in preventing unnecessary disassembly and saves time during repairs.

With the right reference, you gain a better grasp of the structure and functionality of your equipment. Whether it’s for routine upkeep or addressing specific issues, having access to a detailed visual guide ensures that you can make informed decisions and maintain the equipment in optimal working condition.

How to Use the Component Layout Effectively

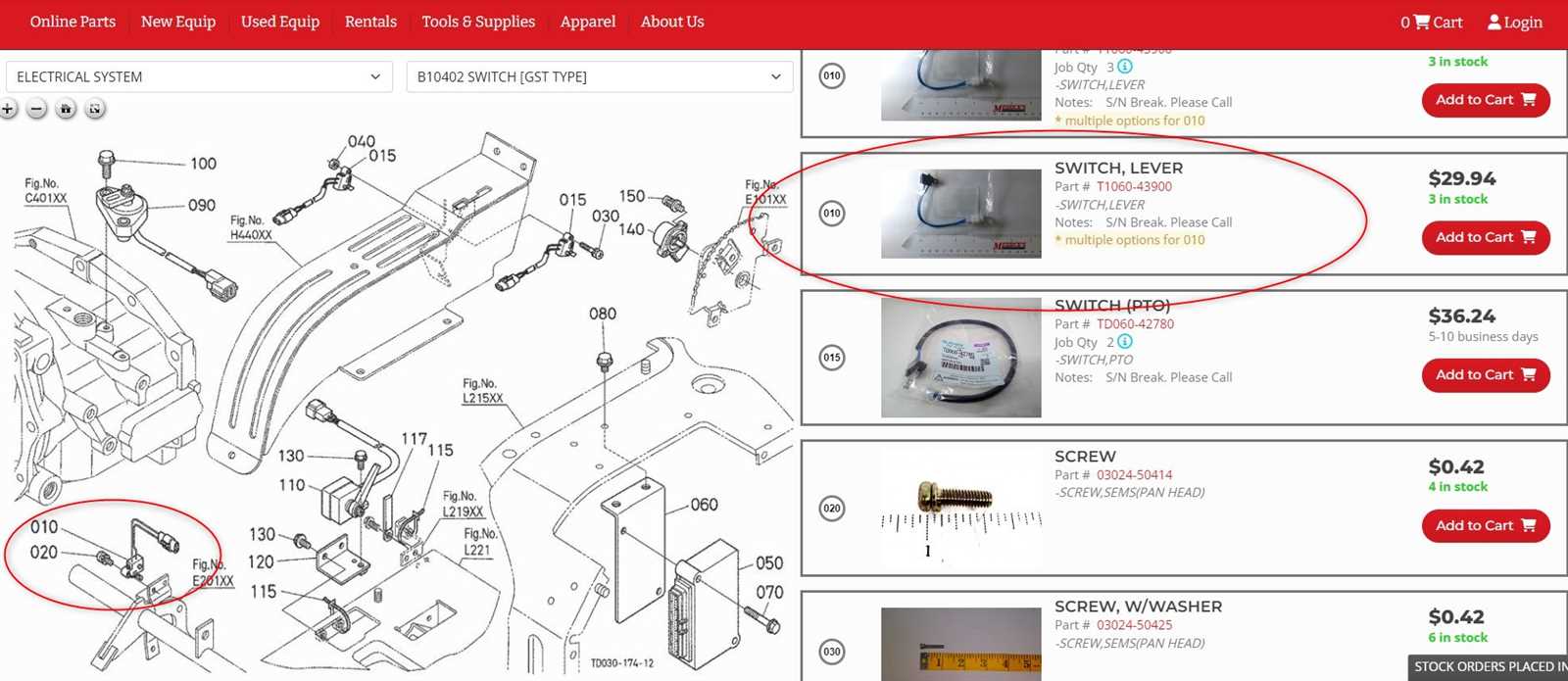

To make the most of a visual guide, it’s essential to understand how to read and interpret it accurately. A well-structured reference will allow you to identify the specific elements you need to focus on and locate them quickly within the machinery. Familiarizing yourself with the layout can significantly speed up the process of maintenance or repairs.

Start by reviewing the key sections of the layout, paying attention to labels and numbering that indicate the placement of different components. This will provide a clear roadmap for locating each part. It’s important to cross-reference the diagram with the physical machine to ensure that the positions and connections are correct before proceeding with any work.

Using such a guide effectively requires a methodical approach. Break down the machinery into smaller sections and work through them systematically. By following this process, you can efficiently troubleshoot issues, identify worn-out components, and avoid unnecessary disassembly. The more familiar you become with the layout, the quicker you can address any concerns that arise.

Common Issues and Solutions with Tractor Components

Every machine experiences wear and tear over time, and it’s not uncommon for certain parts to become faulty or need adjustment. Identifying and addressing these issues early can help prevent more serious breakdowns and costly repairs. In this section, we will cover some of the most frequent problems encountered in machinery and their solutions.

Engine and Transmission Problems

One common issue in machinery is engine or transmission failure, which can result from improper lubrication or the degradation of internal components. To prevent such issues, ensure regular oil checks and fluid changes. If the engine is showing signs of reduced power or difficulty starting, inspect the fuel system and ignition components for clogs or wear. Timely maintenance can extend the life of the machine.

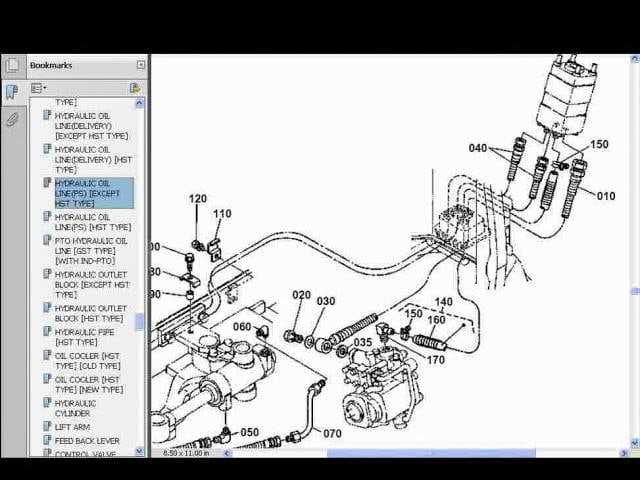

Hydraulic System Malfunctions

Hydraulic failures are also frequent, with leaks or pressure drops being the most common symptoms. These problems are often caused by worn seals or damaged hoses. Inspecting the hydraulic system regularly and replacing worn-out seals and hoses can prevent further damage. If pressure issues persist, check the hydraulic pump and valves for blockages or malfunctioning parts.

Regular maintenance is key to avoiding these issues. By keeping an eye on the condition of your equipment and addressing small problems before they become significant, you can ensure smooth operation and reduce downtime.