In any mechanical system, knowing the specific elements that make up its structure is crucial for proper operation and maintenance. These systems often contain various interconnected parts, each with a unique function that contributes to the overall performance. Whether you’re new to this field or seeking to refine your knowledge, gaining a clear understanding of these components is essential for smooth functionality.

By carefully studying the layout of these systems, it becomes easier to troubleshoot issues, identify necessary repairs, and ensure optimal performance over time. A well-structured guide can provide clarity, allowing you to recognize key components, their roles, and how they interact within the larger mechanism.

Proper identification of each piece is the first step toward effective maintenance. Familiarity with how each element functions and contributes to the system’s success enables a more efficient workflow and ensures long-term reliability.

Understanding Tulsa Winch Components

The foundation of any mechanical system lies in its various elements, each playing a critical role in ensuring smooth operation. These components work in unison, and understanding their functions and interactions is key to maintaining the efficiency of the entire setup. Familiarity with each piece allows for better management and troubleshooting, making it essential to know how they come together.

Key Functional Elements

Each component within the assembly serves a unique purpose. Some parts are responsible for initiating movement, while others ensure stability and control. Recognizing these essential functions allows for a more thorough understanding of the system’s overall performance. Knowing their roles helps diagnose problems and identify areas for improvement.

Maintenance and Care

Proper care of each component extends the lifespan of the entire system. Regular inspection and cleaning are essential for maintaining optimal performance. Routine checks can help catch early signs of wear and tear, ensuring that the system remains reliable over time.

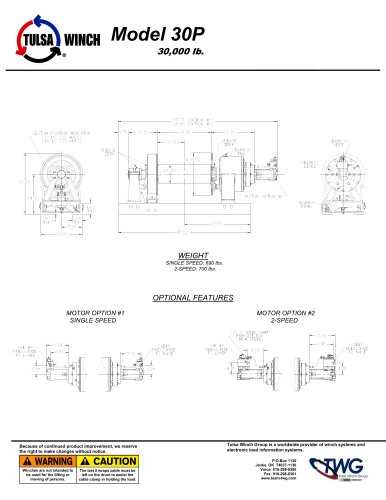

How to Read Tulsa Winch Diagrams

Interpreting visual representations of mechanical systems can be challenging, yet it’s an essential skill for understanding how each component fits and functions within the larger setup. These illustrations provide an overview of the layout, helping users identify the placement and connections of various elements. Mastering this skill simplifies troubleshooting and maintenance tasks.

Decoding Symbols and Labels

In these visual guides, symbols and labels are used to represent each individual piece of equipment. Familiarizing yourself with these symbols is the first step in accurately interpreting the drawing. Each symbol corresponds to a specific function, and understanding what each one stands for makes it easier to follow the entire setup. Clear labeling ensures that users can easily locate parts and understand their roles in the system.

Following the Flow of Connections

The next step is to follow the connections between components. Arrows and lines in the illustration show how different parts interact and communicate with each other. Recognizing these connections helps understand the system’s operation and highlights potential points where issues might arise.

Essential Parts for Winch Maintenance

Regular upkeep of any mechanical system requires attention to key components that ensure smooth operation. Some elements are particularly crucial for maintaining efficiency and preventing unexpected malfunctions. Identifying these critical pieces helps focus on areas that need routine checks and care, ensuring the system remains reliable over time.

Key components, such as the motor, control mechanisms, and moving parts, require regular inspection and occasional replacement. Maintaining these essential pieces prevents wear and tear from causing disruptions, allowing for continuous use without major issues. Neglecting these vital elements can lead to more serious problems that may be costly to repair.

Routine lubrication, cleaning, and proper storage of these parts are also vital practices that help extend their lifespan. Adhering to maintenance guidelines for these specific elements ensures that the system operates optimally, minimizing downtime and improving overall performance.