For any tractor owner, having a clear understanding of the machine’s key elements is essential for effective maintenance and repairs. Knowing how different parts function together ensures that your equipment runs smoothly and reliably, reducing downtime and repair costs. Regular inspections and a basic grasp of the machine’s structure can prevent unexpected issues and extend its lifespan.

In this guide, we will explore how to identify various components of a tractor and their specific roles. We’ll also discuss how to interpret the layout of these components to make repairs and maintenance tasks easier. Whether you’re a seasoned professional or a first-time owner, understanding your machine’s construction is a valuable skill.

Additionally, we will cover best practices for upkeep to keep everything running efficiently. Regular maintenance, when done correctly, can save both time and money in the long run, while also ensuring that the tractor stays in top working condition throughout its service life.

Understanding the Tractor Components

Every tractor is composed of multiple interconnected systems, each designed to perform specific functions. These elements work together to ensure the machine operates efficiently, and understanding how they interact is crucial for troubleshooting and maintenance. The core components of a tractor include the engine, transmission, hydraulics, and various control systems, all of which must be in top condition for the machine to perform its best.

By examining the tractor’s configuration, it’s possible to identify key systems and their roles in the overall operation. Each section has its unique function, from providing power and propulsion to controlling fluid flow and mechanical movement. Whether you are conducting routine checks or performing a detailed repair, understanding these individual parts makes the process more manageable and efficient.

In this section, we will break down the major components, highlighting their importance and how they contribute to the tractor’s functionality. This knowledge will serve as a foundation for further exploration of the machine’s upkeep and repairs.

Identifying Key Parts in the Layout

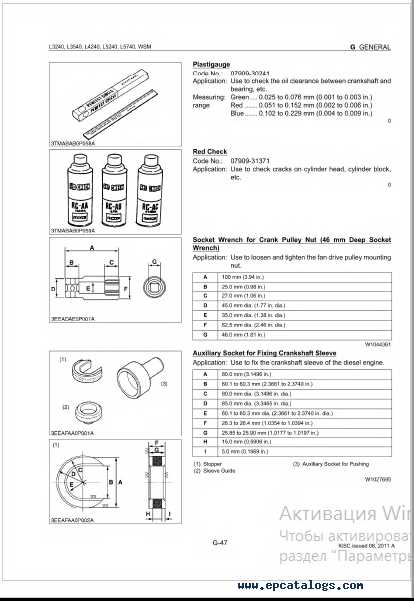

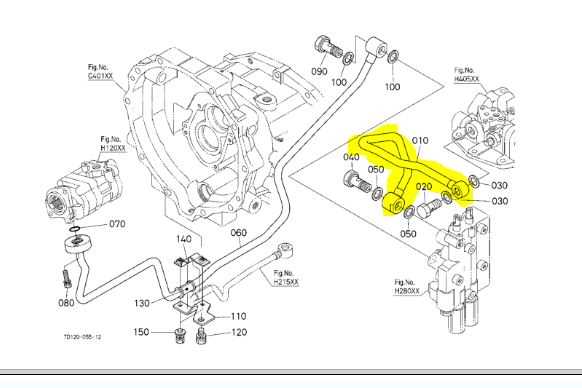

Understanding how the components of a machine are organized is essential for proper maintenance and troubleshooting. Visual aids that outline the various elements of a tractor allow users to quickly identify and locate different sections. These layouts serve as a valuable tool, providing clarity on where each part is situated and how it fits into the broader system of the vehicle.

Locating Essential Systems

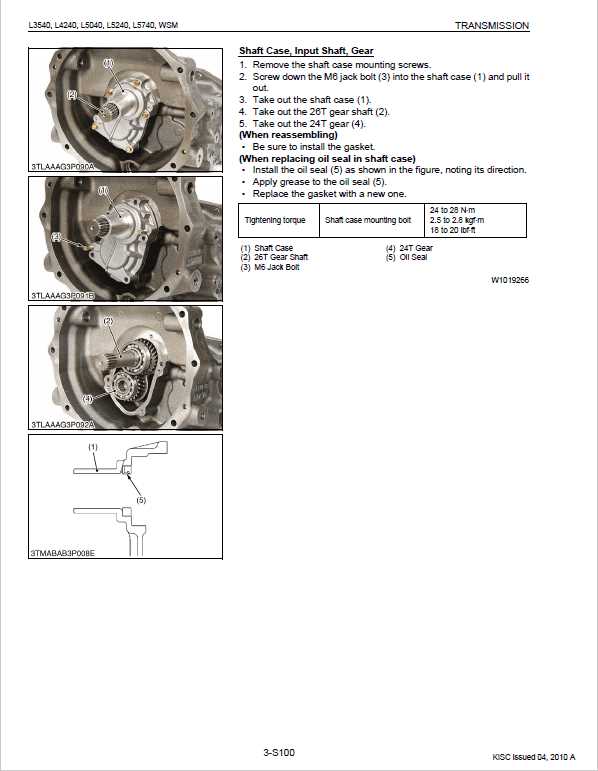

Focusing on the primary systems, such as the engine, transmission, and hydraulic units, helps users identify the most important areas that require attention. By reviewing their placement in the visual layout, it becomes easier to locate where specific issues might arise and which sections need inspection or repair. This proactive approach can save time and prevent unnecessary disassembly of unrelated parts.

Understanding Component Interaction

Recognizing how the components interact with each other is just as important as knowing their individual locations. The layout provides insights into how different parts connect and function in harmony. This understanding is key for diagnosing issues and performing efficient maintenance, as it helps users see potential problem areas that could affect multiple systems at once.

Maintenance Tips for Tractor Components

Proper upkeep of a tractor is essential to ensure its longevity and optimal performance. Regular maintenance helps prevent breakdowns, improves efficiency, and reduces repair costs. By understanding which areas require routine checks, owners can keep their equipment in top condition for a longer period. A well-maintained machine operates more smoothly, delivering better results on the field and reducing the risk of costly repairs.

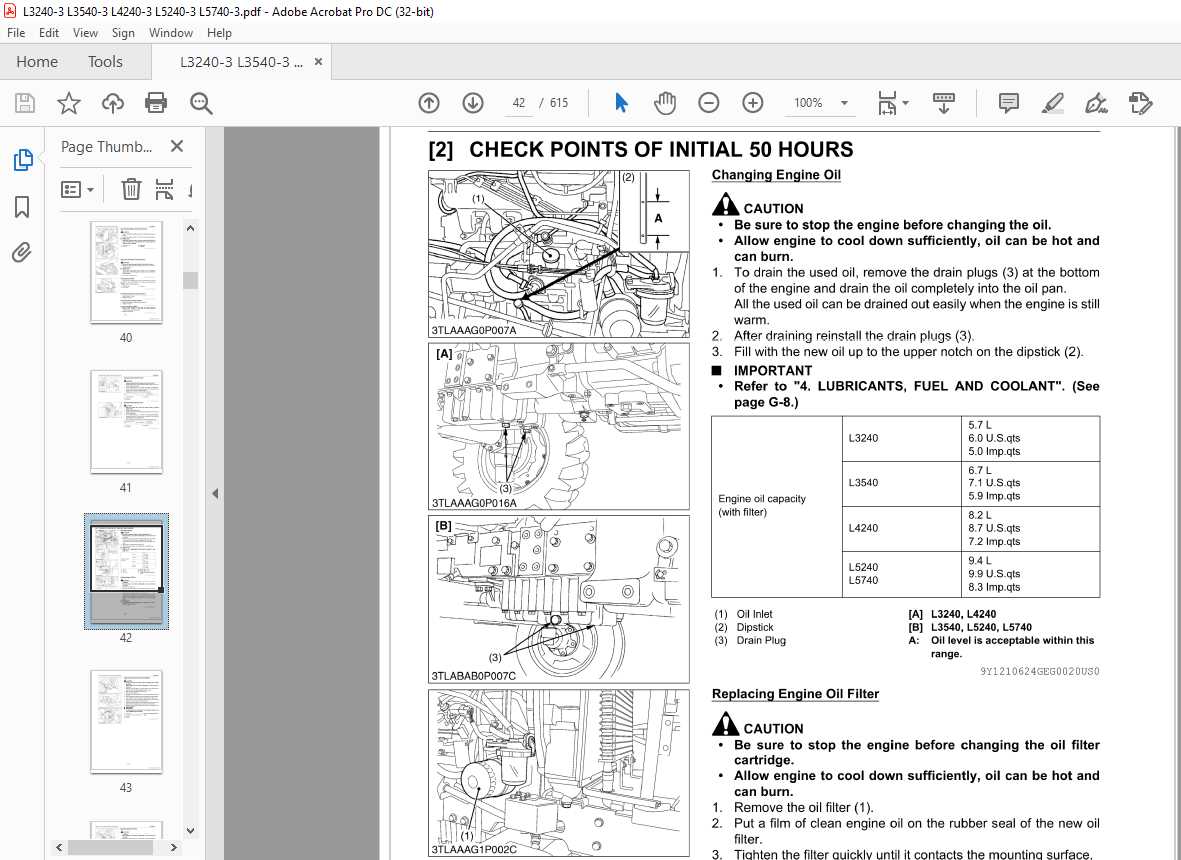

Regular Inspection of Critical Systems

It’s important to inspect essential systems such as the engine, transmission, and hydraulics frequently. These systems are responsible for the core functions of the machine, and any sign of wear or malfunction can affect overall performance. Regularly checking fluid levels, belts, hoses, and filters can prevent minor issues from turning into major problems.

Cleaning and Lubrication

Keeping the tractor clean is vital for maintaining its functionality. Dirt and debris can cause parts to wear down prematurely, leading to system failures. Regularly cleaning areas like the cooling system, air intake, and engine parts ensures that they stay free from blockages and maintain proper airflow. Additionally, lubricating moving components reduces friction and wear, enhancing their lifespan and performance.