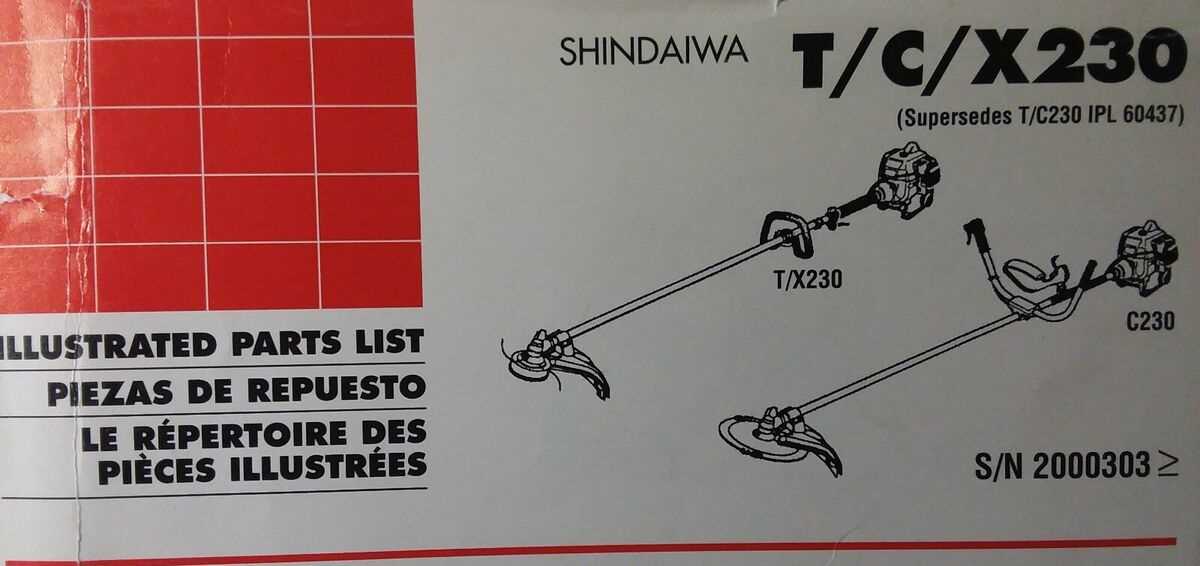

When maintaining or repairing outdoor machinery, having a clear visual guide to its various elements can make all the difference. By understanding how each part fits together and functions, you can ensure optimal performance and longevity. This guide provides an essential overview for users seeking to identify and address issues with their tools effectively.

Knowing the right components is key to diagnosing malfunctions and replacing worn-out parts. By referring to a detailed schematic, users can pinpoint which pieces need attention and how to approach repairs. It’s an invaluable resource for anyone looking to extend the lifespan of their equipment.

Whether you’re a seasoned user or new to maintenance tasks, understanding the configuration and layout of your tool’s internal workings will help you make informed decisions about replacements and repairs.

Understanding Key Components

To properly maintain and repair your outdoor machinery, it’s important to familiarize yourself with the essential elements that make up the device. Each component plays a specific role, contributing to the overall functionality and efficiency of the tool. Knowing these parts helps in identifying wear and tear and ensures that the machine operates at its best.

Identifying Core Components

The key components of your equipment are responsible for its smooth operation. These include the engine, handle assembly, and control mechanisms, each of which interacts to perform a variety of tasks. Understanding the function of each piece allows for easier troubleshooting when something goes wrong.

Assembly and Disassembly Process

Knowing how each part fits together is just as crucial as understanding what it does. Proper assembly and disassembly techniques ensure that the machine is not damaged during repairs. It’s essential to follow manufacturer guidelines to avoid unnecessary issues and keep the device running efficiently.

How to Read the Parts Diagram

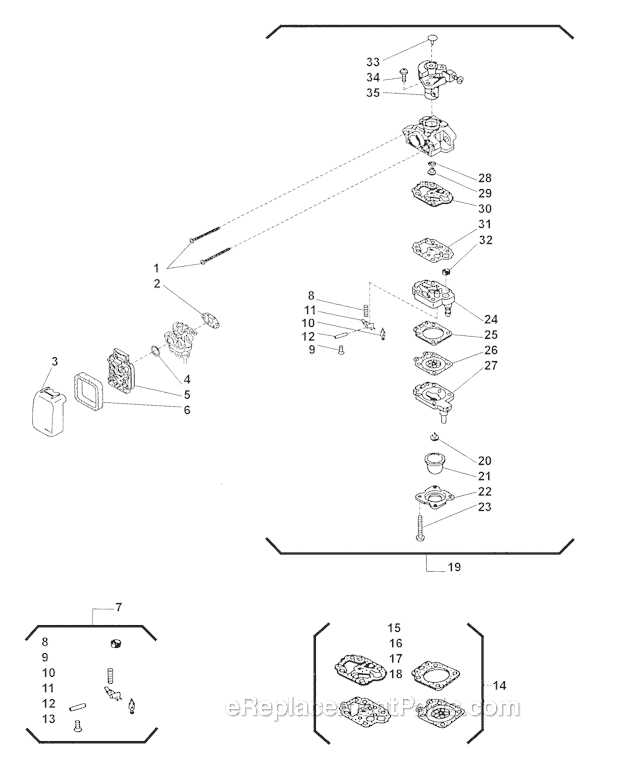

Understanding a component illustration is essential for properly identifying and working with the various elements of a machine. This visual guide helps users recognize each part’s function and location within the system, facilitating easier assembly, maintenance, and repairs.

Begin by familiarizing yourself with the reference numbers or labels assigned to each piece. These identifiers correspond to a list, which provides detailed descriptions and part numbers. Pay attention to the grouping of components, as it often indicates how the pieces work together in the overall structure.

Key to interpretation: Focus on the layout of the image. The arrangement of components can reveal assembly order, connections, and dependencies between parts. The use of different colors or shading might highlight specific sections, making it easier to follow the steps.

Tip: Always compare the illustration with the actual machine to ensure correct identification. This ensures that the parts are replaced or serviced in the right sequence and position.

Common Issues and Replacement Parts

Over time, machines may experience wear and tear, leading to performance issues or malfunctions. Identifying the root cause of these problems is crucial for effective repair. Often, these issues can be resolved by replacing damaged or worn-out components.

Frequent Problems and Solutions

One of the most common issues is a lack of power or inefficient operation. This could be due to a clogged air filter or damaged fuel line, both of which can be easily replaced. Another issue might involve difficulty starting, often caused by a malfunctioning ignition coil or spark plug.

Identifying Replacement Items

When replacing components, it’s important to ensure compatibility with the existing machine. Always refer to the manual for the correct model numbers. Reliable replacements include components such as fuel filters, spark plugs, and air filters. Regular maintenance and timely replacement will help extend the life of your equipment.

Pro tip: Keep track of the most frequently replaced items in your toolkit to ensure quick fixes when issues arise.