Maintaining and repairing a lawn tractor requires a thorough understanding of its internal mechanisms. A clear view of how each component fits together and functions can make troubleshooting and part replacement much easier. For owners of such equipment, having access to a detailed visual representation is essential to ensure smooth operation and long-term durability.

By studying the assembly layout of your machine, you can identify the correct parts, recognize common issues, and quickly pinpoint the cause of any malfunctions. This information is particularly useful when ordering replacements or performing routine maintenance. With the right resources, even complex repairs can become manageable tasks, saving both time and money.

In this guide, we’ll explore how to interpret these visual schematics and offer insights on addressing typical repair needs. Understanding these guides will empower you to take control of your equipment’s upkeep with confidence.

Understanding the Kubota TG1860 Parts Layout

For any owner of a lawn tractor, it’s important to understand how the various components interact and contribute to the machine’s performance. The layout of these components provides a map for identifying each part’s function, placement, and connection to the overall system. This knowledge is invaluable for anyone looking to maintain their equipment or perform repairs effectively.

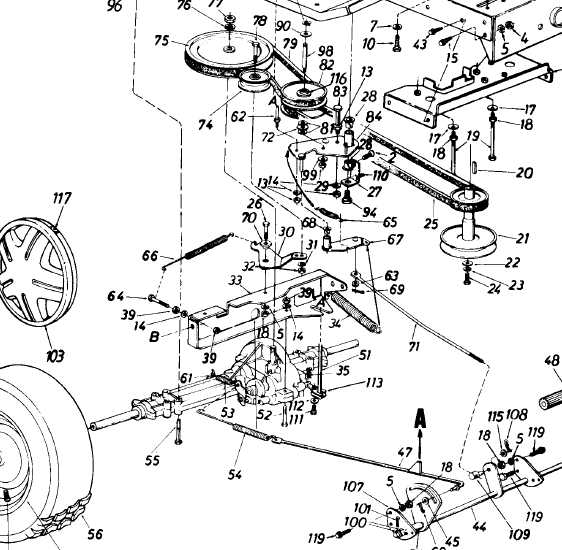

How to Read the Assembly Overview

The assembly map typically offers a detailed view of the machine’s structure, displaying how different elements are connected. It highlights key areas like the engine, transmission, wheels, and steering mechanisms, making it easier to visualize the flow of power and the movement of parts. By familiarizing yourself with this layout, you can spot wear and tear or signs of malfunction in a specific area more efficiently.

Practical Applications of the Layout

Once you understand the layout, you can use it to streamline repair processes. Whether replacing a worn-out belt or fixing a malfunctioning engine component, knowing the exact location of each part will save time and reduce the risk of errors. This approach ensures that every part is handled with care, improving the longevity and functionality of the equipment.

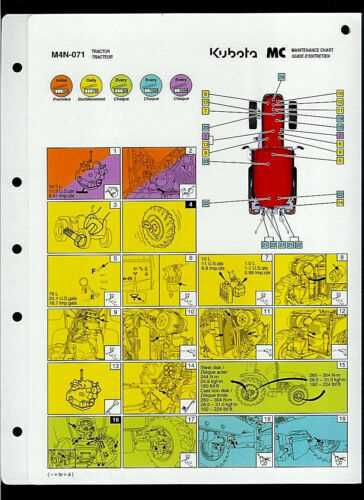

How to Use the Kubota Parts Diagram

Utilizing a visual guide to your equipment’s assembly can simplify the repair and maintenance process. These schematics offer a clear representation of how each component fits within the system, making it easier to identify, replace, or troubleshoot individual elements. By following these guides, you can ensure accuracy and efficiency when working on your machine.

Step-by-Step Instructions for Effective Use

To start, locate the specific section that corresponds to the area of the equipment you’re working on. Each section is typically broken down into smaller components, which can be referenced when looking for specific replacements or performing repairs. The numbers or labels next to each part allow for easy identification, making it simple to match components with their corresponding identifiers in parts catalogs.

Benefits of Following the Guide

Using this guide prevents confusion and mistakes during maintenance. Whether you’re assembling a new component or replacing an old one, the visual map helps maintain the integrity of your machine. It also minimizes the risk of overlooking critical parts or connections, which is essential for keeping the equipment running smoothly and preventing further damage.

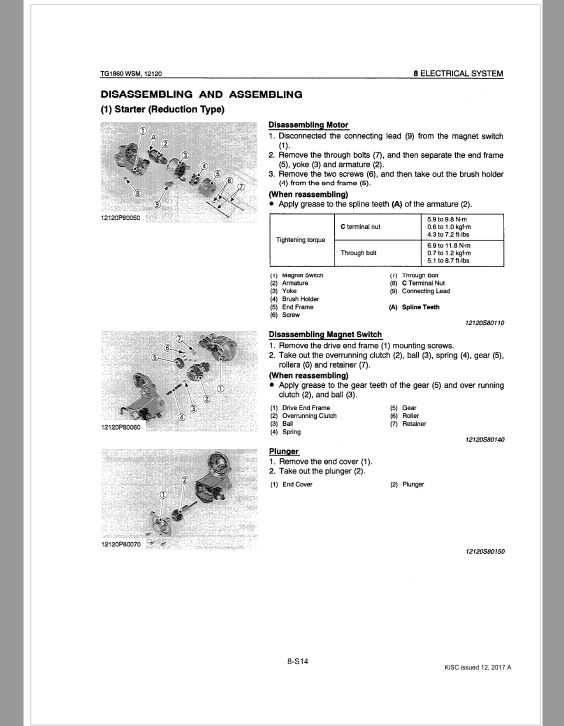

Common Issues and Part Replacements for Kubota TG1860

As with any machine, regular use can lead to wear and tear on various components. Identifying common issues early can prevent more serious damage and costly repairs down the line. Understanding the most frequent problems and knowing how to address them will help keep your equipment in top condition for years to come.

Frequent Mechanical Problems

One of the most common issues involves the engine misfiring, which may result from a clogged fuel filter or damaged spark plugs. These are easy to diagnose and replace with minimal tools. Another issue often faced is transmission failure, which can occur if gears become worn or the fluid levels are low. Regularly checking fluid levels and replacing old parts can extend the life of the transmission significantly.

Replacing Worn Components

Over time, belts and cables are often the first components to show signs of wear. These parts are crucial for the smooth operation of the equipment, and replacing them promptly ensures no disruptions during use. Additionally, keeping an eye on tire tread and steering components can help prevent accidents or difficult handling during operation.