Having a clear understanding of the essential elements that make up your crafting tool is crucial for smooth operation and longevity. Proper knowledge helps in maintaining, troubleshooting, and optimizing its performance. Identifying these components allows you to make informed decisions on repairs and improvements.

Efficient maintenance becomes much easier when you are familiar with the specific elements within your device. Each part plays a critical role, from the fundamental functions to the intricate mechanisms that enable complex tasks. Being able to recognize and understand their purposes can save both time and resources.

By breaking down the structure into clear sections, users can tackle each component individually, improving their overall experience. This approach ensures that the tool remains in top working condition, allowing for greater productivity and satisfaction in your work.

Understanding Viking Sewing Machine Components

Every tool consists of numerous elements that work together to ensure its functionality. Each component has a unique role, contributing to the overall performance of the device. A well-structured system makes tasks easier, faster, and more efficient, so knowing how each piece contributes is essential for maximizing its potential.

Key Elements of the System

The primary components within the tool include mechanisms responsible for movement, adjustment, and control. These crucial parts ensure the device runs smoothly and effectively. Familiarity with each element enables users to address issues promptly and carry out necessary maintenance tasks, keeping everything in optimal condition.

Maintaining Optimal Functionality

Regular checks and understanding the purpose of each individual element can prevent common malfunctions. Knowing how to disassemble, clean, and reassemble these components properly will lead to a more durable tool. Additionally, understanding the function of each mechanism allows users to troubleshoot problems with ease, reducing downtime and improving overall productivity.

How to Identify Key Sewing Machine Parts

Recognizing the essential components of your tool is the first step in understanding how it functions. Knowing what each element does helps in troubleshooting, performing repairs, and enhancing the efficiency of the device. It’s important to familiarize yourself with these key sections to ensure smooth operation.

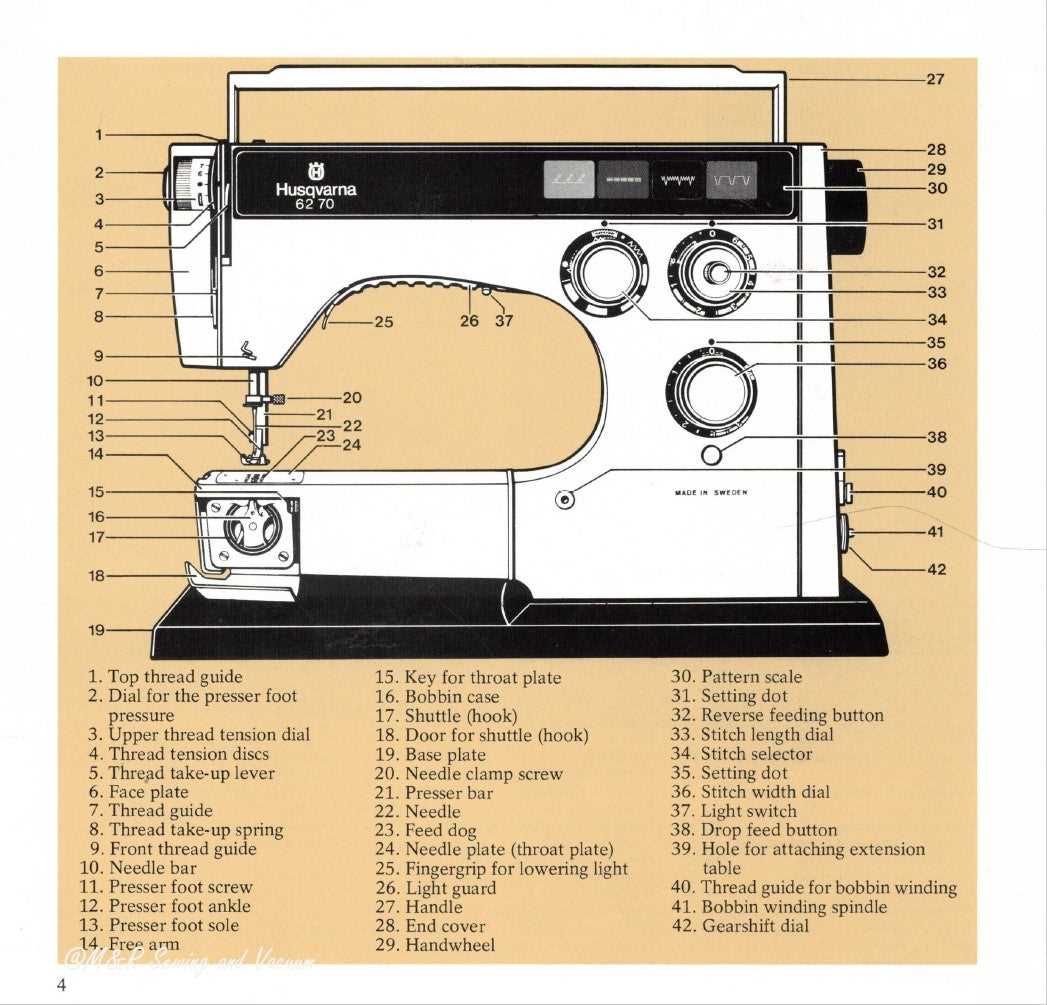

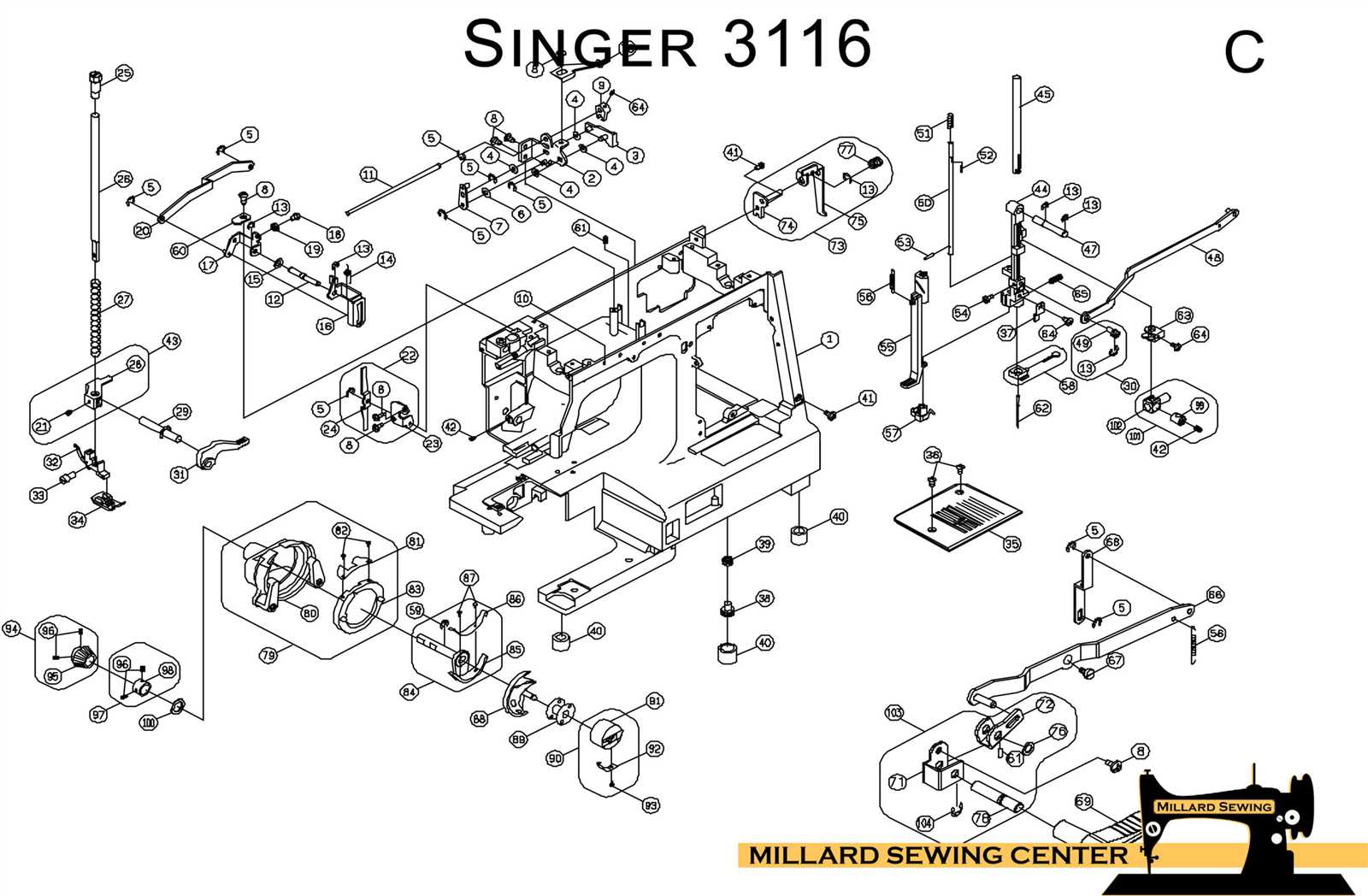

Recognizing Major Components

The key sections you will encounter include the feeding system, the tension mechanism, and the needle holder. Each plays a pivotal role in ensuring that the process flows seamlessly. For example, the feeding system controls the movement of fabric, while the tension system regulates the thread, preventing common issues like snagging.

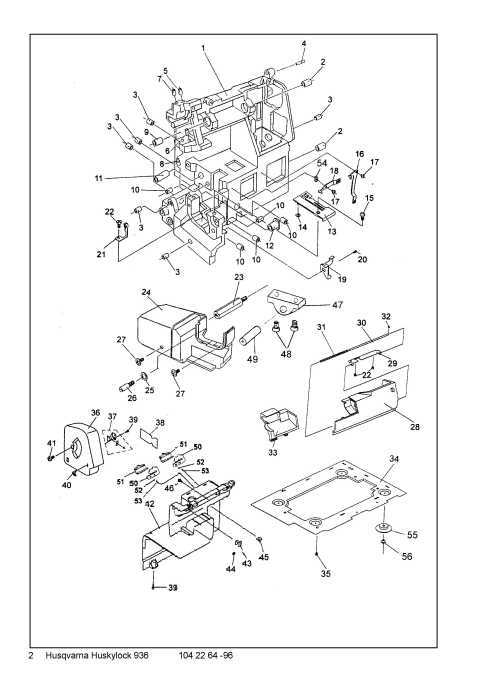

Understanding the Assembly

When examining the tool, look for the primary units that interact during use. The most critical components are typically located near the operational area and are easy to identify once you become familiar with their functions. Familiarity with these parts also aids in ensuring everything is in the right alignment for accurate and efficient performance.

Common Viking Machine Issues and Fixes

Even the most reliable tools can experience occasional issues. Understanding the common problems that arise and knowing how to address them ensures the longevity and efficiency of the equipment. Proper diagnosis and quick fixes can prevent disruptions and improve the overall experience.

Thread Jamming or Breakage

One of the most frequent issues is thread jamming or breakage. This can happen due to incorrect threading, tension imbalances, or improper needle choice. To fix this, check the thread path for any obstructions, adjust the tension settings, and ensure you are using the right needle type for the fabric being worked on.

Uneven Stitching or Skipped Stitches

Another common problem is uneven stitching or missed stitches, which can result from issues with the needle, tension, or feed mechanism. If you encounter this problem, replace the needle if it is dull or bent, adjust the tension settings, and ensure the fabric is feeding evenly through the system.