Understanding the various elements that make up a lawn maintenance tool is crucial for ensuring its longevity and optimal performance. Each component plays a vital role in the tool’s overall function, from the motor to the attachment system. Knowing how these parts work together can help users troubleshoot issues and maintain their equipment effectively.

Properly identifying the key components and how they interact allows for easier repairs and part replacements. Regular inspections can prevent unexpected breakdowns and ensure smooth operation. A clear understanding of the tool’s internal structure provides users with the knowledge they need to care for their equipment and maximize its efficiency.

Understanding the Components of Lawn Tool

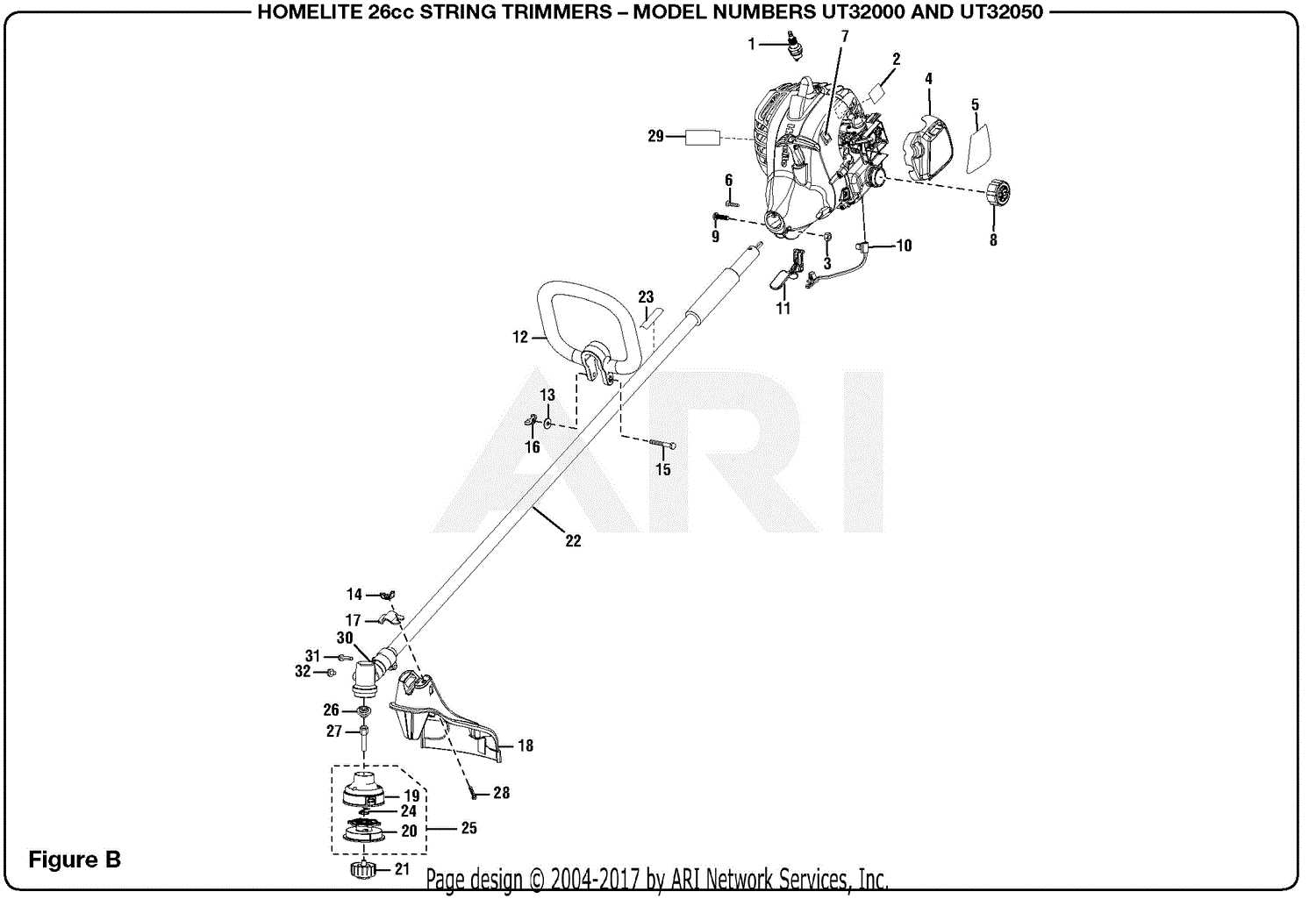

To operate any garden maintenance tool effectively, it is important to familiarize oneself with the various components that contribute to its functionality. A solid understanding of how each part works individually and as a whole ensures better performance and easier troubleshooting. Every element, from the engine to the cutting system, has a specific purpose that supports the tool’s efficiency.

Key Elements of the Tool

- Motor – Powers the device and drives the cutting mechanism.

- Handle – Provides a secure grip and allows for better control during operation.

- Cutting Mechanism – Includes various attachments like blades or trimmer heads that perform the task of cutting vegetation.

- Trigger – Controls the power flow to the motor, allowing for easy start and stop functions.

- Support Frame – Holds all the components in place and helps maintain the structure of the tool.

Understanding Their Functions

Each component of the tool works in harmony with the others to ensure smooth operation. The motor, for example, needs to be adequately maintained to avoid overheating and loss of power. The cutting mechanism relies on sharpness and functionality to ensure efficient trimming, while the handle and trigger offer the user control and safety. Regular maintenance of each part is essential to preserve the tool’s reliability over time.

How to Identify Key Parts for Repair

Recognizing the crucial components that need attention during maintenance or repair is vital for restoring a tool’s functionality. When an issue arises, knowing which element is malfunctioning or worn out will save time and resources. Identifying these elements accurately allows for targeted repairs rather than unnecessary replacements.

Signs of Malfunctioning Components

- Loss of Power – If the tool doesn’t start or loses power during use, the motor or trigger may be malfunctioning.

- Unusual Noise – A loud or grinding noise could indicate issues with the cutting mechanism or motor.

- Excessive Vibration – This often points to an imbalance in the cutting system or a loose attachment.

- Difficulty Starting – Troubles with the ignition or power supply system are typically the cause of starting issues.

Steps to Identify Problematic Parts

- First, perform a visual inspection of all components for signs of wear or damage.

- Check for any loose or disconnected parts that may hinder performance.

- Test the tool’s functionality by running it briefly to identify unusual sounds or behaviors.

- Consult the user manual to confirm specifications and check compatibility with replacement parts.

Common Issues and Maintenance Tips

Proper upkeep is essential for any garden tool to ensure it operates efficiently. Regular attention to common problems and performing routine maintenance can significantly extend the lifespan of the equipment. Identifying issues early on and addressing them promptly is key to avoiding major repairs.

Frequent Problems

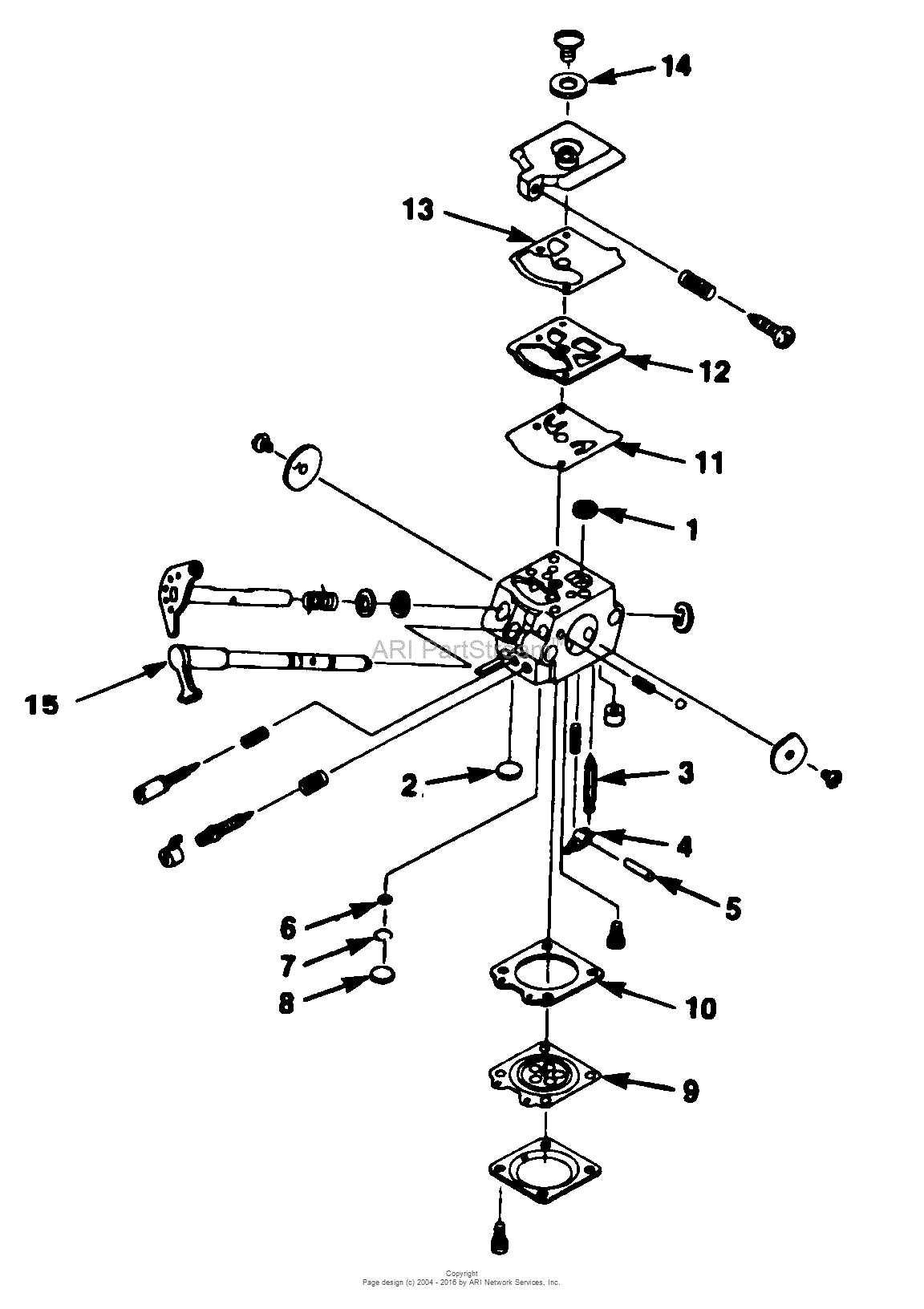

- Motor Overheating – This can happen due to clogged vents or a lack of lubrication. Ensuring that the motor is clean and well-lubricated can prevent this issue.

- Loss of Cutting Efficiency – A dull blade or worn-out cutting attachment can cause uneven trimming. Regular sharpening and replacing damaged parts can help maintain performance.

- Starting Difficulty – A clogged fuel system or faulty spark plug may cause problems starting the tool. Checking the fuel line and cleaning or replacing the spark plug can resolve this.

Maintenance Recommendations

- Clean the Tool After Use – Removing dirt and debris after every use will prevent buildup and ensure smooth operation.

- Regularly Check for Loose Components – Tightening any loose screws or bolts will prevent wear and tear on critical parts.

- Inspect the Fuel System – Ensure that fuel is fresh and the system is free of contaminants to avoid engine issues.

- Store Properly – Keeping the tool in a dry place will prevent rusting and damage from exposure to the elements.