When it comes to maintaining your outdoor space, knowing the structure of your equipment is essential for smooth operation. A well-maintained machine ensures better performance, efficiency, and longevity. Familiarizing yourself with how different components work together can save time and prevent unnecessary repairs.

Whether you’re troubleshooting an issue or performing regular upkeep, understanding each part’s role will help you identify problems quickly. This knowledge also enables you to make informed decisions about replacing or repairing specific sections of the equipment.

By diving into the details of the various elements, you’ll gain a clearer understanding of how to properly care for and maintain your outdoor machinery. A strong grasp of these components not only enhances functionality but also extends the lifespan of your equipment.

Understanding Equipment Component Functions

Each machine designed for outdoor tasks consists of multiple essential elements that work in harmony to ensure smooth operation. A clear understanding of how these components interact allows users to diagnose issues, perform repairs, and maintain overall functionality. Recognizing the purpose of each section helps in recognizing wear and tear early, which ultimately extends the life of the equipment.

Key Elements in a Functional System

Every device used for yard maintenance relies on several fundamental sections. The engine, drive system, and cutting mechanism are the core components that determine the machine’s efficiency. By understanding how these parts collaborate, users can spot malfunctions or inefficiencies, ensuring the equipment functions as intended.

Maintaining Optimal Performance

Routine checks on the moving parts, such as belts and blades, contribute to maintaining high performance. Regularly cleaning and replacing worn components can prevent system failure and keep your machine running smoothly for longer periods. Proactive care minimizes downtime and boosts efficiency during every use.

How to Identify Key Yard Equipment Components

Recognizing the key elements of any outdoor machine is essential for effective maintenance and troubleshooting. Identifying each component’s function not only helps you manage repairs but also ensures your equipment operates efficiently. By becoming familiar with these vital parts, you can detect any issues early, saving both time and money in the long run.

Recognizing the Engine and Drive System

The engine serves as the heart of your equipment, powering all other components. It is crucial to understand its connection with the drive system, which transfers power to the wheels or blades. A well-maintained engine will ensure the machine operates smoothly, while any issues within the drive system may cause sluggishness or difficulty in maneuvering.

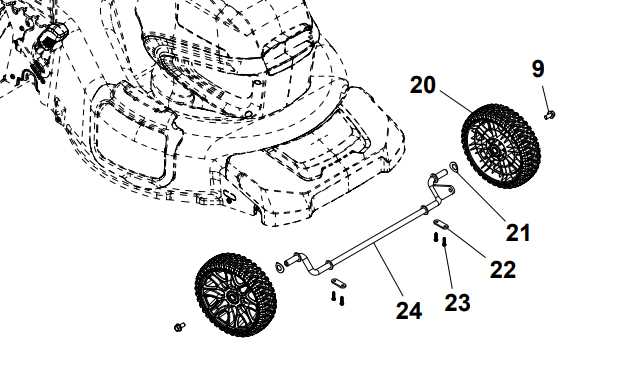

Understanding the Cutting Mechanism

The cutting assembly is a vital section that directly impacts the performance of your equipment. This mechanism includes the blade or blades that perform the primary task of trimming grass or foliage. Regular inspection of the blades and their alignment ensures optimal cutting results, while dull or damaged blades can lead to poor performance.

Common Repairs with Yard Equipment

Like any mechanical device, outdoor equipment requires regular repairs to maintain optimal performance. Common issues usually arise due to wear and tear or inadequate maintenance. By understanding the most frequent problems and their solutions, users can save time and money while ensuring their tools remain in working order.

Engine and Starting Issues

One of the most common repairs involves issues with the engine failing to start or running inefficiently. Problems may stem from clogged fuel lines, dirty spark plugs, or a depleted fuel tank. Regularly inspecting these components and replacing them when necessary ensures the engine remains reliable and functional.

Problems with the Cutting System

Another frequent issue is related to the cutting assembly. Blades may become dull, misaligned, or damaged, leading to poor cutting performance. Ensuring that the blades are sharp, properly balanced, and securely attached is key to maintaining efficient trimming. Additionally, checking the blade’s mounting system for any signs of wear is important for long-term use.