Maintaining and repairing a land mower requires a clear understanding of its individual components. These machines consist of various elements, each playing a crucial role in ensuring smooth performance. Knowing how each piece interacts with the others is essential for diagnosing issues, performing routine maintenance, and maximizing the machine’s lifespan.

The structure of these machines is relatively simple, but identifying the correct function of each part can often be challenging. From the cutting mechanism to the structural framework, every part must work in harmony for optimal results. Proper knowledge of these components helps in making informed decisions regarding repairs, upgrades, and maintenance practices.

In this guide, we will break down the different sections of the equipment, explaining their function and importance in detail. Whether you are a first-time user or a seasoned operator, understanding these elements will equip you with the skills to maintain your mower in top condition.

Understanding the Equipment Components

The performance of land mowing machinery heavily relies on the proper functioning of its internal and external components. Every element, from the engine to the blades, is integral to the machine’s overall efficiency. A well-constructed system ensures that each part contributes effectively, allowing the equipment to handle various tasks in a seamless manner.

Main Functional Sections

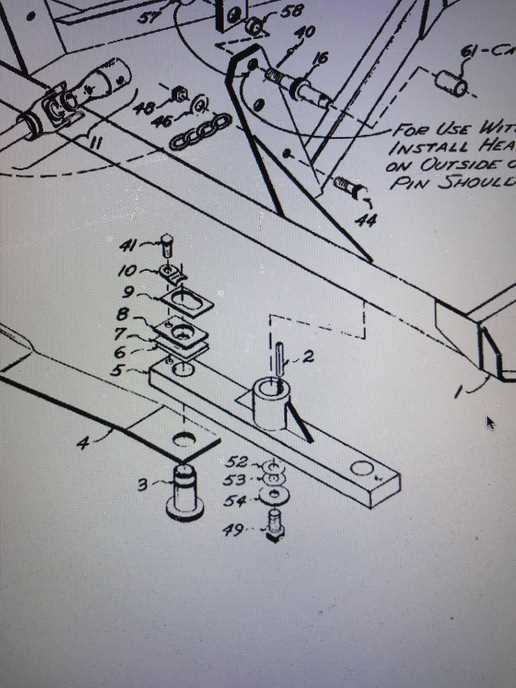

At the core of the machine are the key operational parts, such as the cutting blades, drive system, and frame. These elements work together to provide power and mobility, allowing the machine to clear land quickly and efficiently. The cutting mechanism, often the most visible part, requires sharp, durable materials to withstand tough environments, while the drive system ensures that power is distributed to the right areas at the right time.

Supporting Elements for Smooth Operation

In addition to the main components, supporting features like the hydraulic systems, safety mechanisms, and control levers are just as critical. These parts help regulate power, ensure the safety of the operator, and maintain stability during use. Regular inspection of these systems can prevent many common operational issues, ensuring the machine performs well for years.

Essential Parts for Efficient Operation

The key to smooth and effective land clearing lies in the correct functioning of the core components of the machinery. For optimal performance, certain elements must be in top condition, working together to ensure that the equipment operates without interruption. Understanding these critical pieces is essential for maximizing efficiency and reducing downtime.

Cutting Mechanism and Blade Assembly

The cutting system is the heart of the machine, responsible for performing the main task. Sharp, durable blades are necessary to handle tough vegetation and soil. This section not only requires strong materials but also must be well-maintained to prevent damage or wear. Regular sharpening and replacement of the cutting edges are essential for maintaining consistent results.

Power Transmission and Drive System

The drive system, including the gearbox and drive shaft, is vital for transferring power from the engine to the cutting mechanism. A well-functioning transmission ensures that energy is delivered efficiently, allowing the machine to perform at its best without unnecessary strain on the engine. Regular checks and proper lubrication of these components are crucial to prevent breakdowns and maintain smooth operation.

Common Issues and Maintenance Tips

Even the most reliable equipment can face challenges over time, especially when exposed to tough operating conditions. Recognizing common problems early and implementing a regular maintenance routine can significantly extend the lifespan of the machinery. By staying ahead of potential issues, users can prevent costly repairs and downtime.

Frequent Problems and Troubleshooting

One of the most common issues is blade wear and tear. Over time, blades can become dull or damaged, leading to inefficient cutting and potential engine strain. It’s important to inspect the blades regularly for signs of damage and replace them when necessary. Another frequent problem is with the drive system, where components such as the gearbox or drive belt can become loose or worn out. Periodic inspection and adjustments to the tension can help prevent these issues from escalating.

Maintenance Practices for Longevity

Routine maintenance is the key to avoiding many operational issues. Ensuring that all moving parts are properly lubricated is essential for smooth performance and to prevent excessive wear. Additionally, checking hydraulic systems, tightening bolts, and ensuring safety mechanisms are functioning correctly will reduce the risk of breakdowns. Staying on top of these tasks can make a significant difference in the efficiency and reliability of the equipment over the long term.