Maintaining and repairing garden machinery can seem daunting, especially when dealing with unfamiliar parts. Understanding how different components interact is key to ensuring the longevity and efficiency of your equipment. Whether you’re a professional landscaper or a gardening enthusiast, knowing your tools inside and out is crucial for proper care and troubleshooting.

One of the best ways to familiarize yourself with the inner workings of your machines is by consulting a detailed reference that highlights each individual element. This guide will help you navigate through the different components and provide a clearer picture of how they contribute to the overall function of your equipment. Having this knowledge at hand can make the repair process quicker and more effective.

With the right understanding, you’ll be able to identify issues before they become major problems. Whether it’s replacing a worn-out part or making adjustments, a solid grasp of your machine’s structure will save both time and money in the long run.

Understanding County Line Tiller Components

Every piece of gardening machinery consists of various elements that work together to achieve optimal performance. Each component plays a specific role, contributing to the overall functionality of the equipment. By becoming familiar with these parts, you can more effectively troubleshoot and maintain your machine, ensuring it continues to operate smoothly over time.

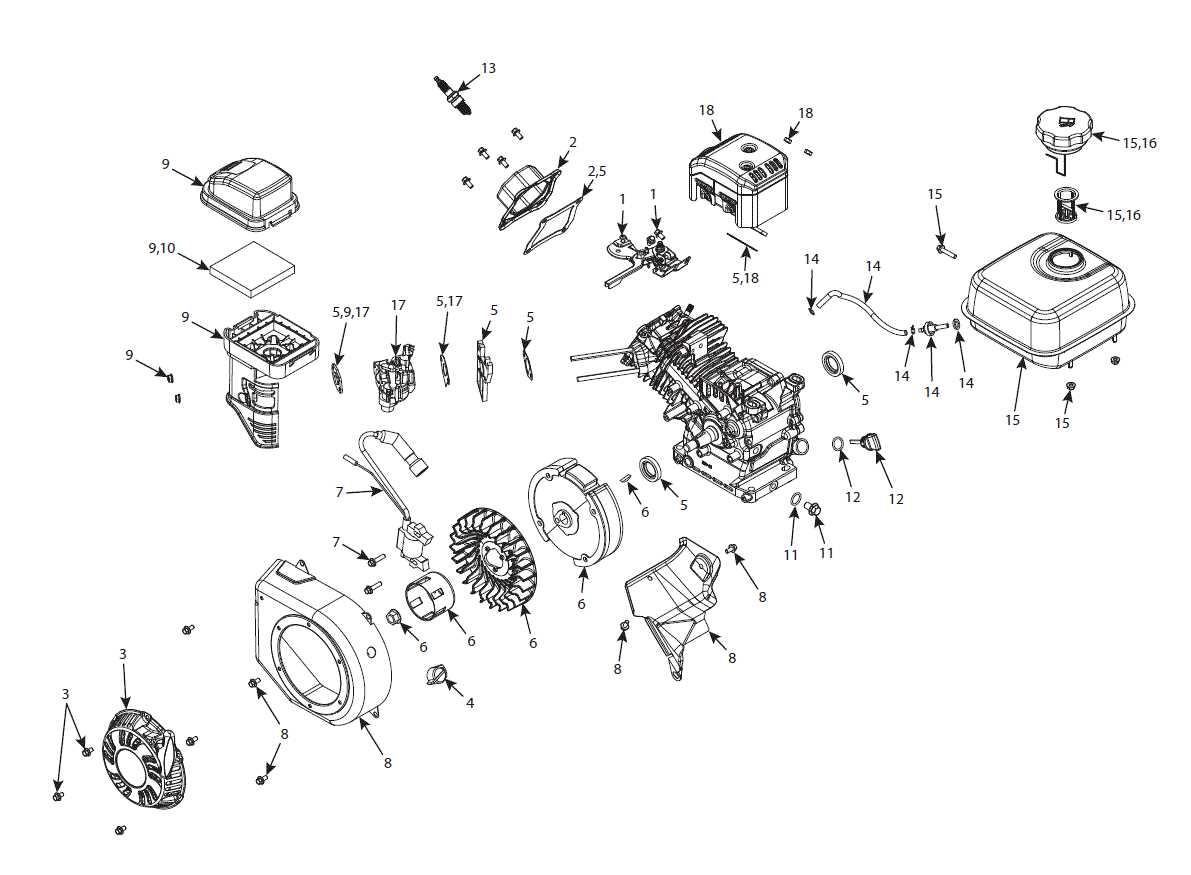

The core components include the engine, transmission, and cutting tools, all of which interact to facilitate soil cultivation. Understanding how each part functions individually and in conjunction with the others helps in recognizing potential issues before they escalate. This knowledge empowers users to perform repairs or replace damaged parts with confidence.

Additionally, certain features, such as adjustable handles or depth settings, allow for customization based on user preferences and terrain. Familiarity with these adjustable components ensures you get the most out of your machine, whether you’re working on a small garden plot or a larger area. Proper maintenance and understanding of each part will contribute to a longer lifespan and improved efficiency in your gardening tasks.

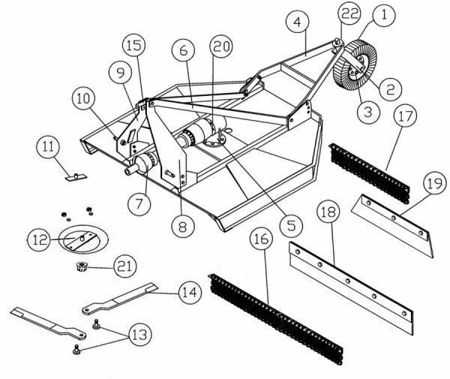

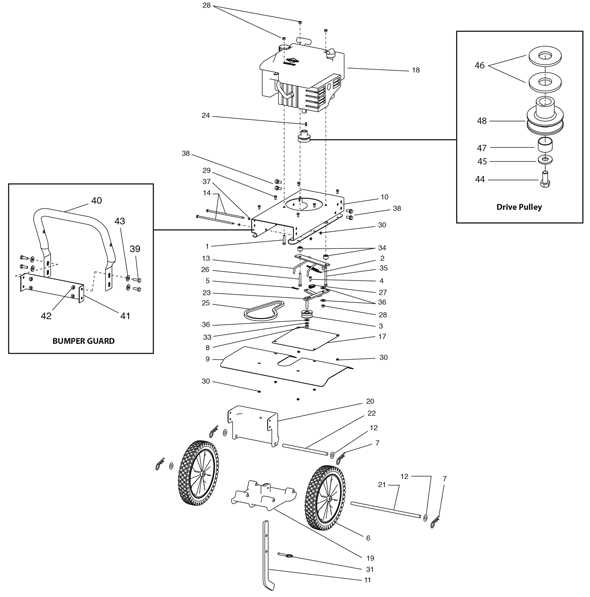

How to Read a Tiller Parts Diagram

Understanding the layout of a machinery reference guide is essential for any repair or maintenance work. These illustrations provide a visual map of all the components, showing how each part fits into the overall system. By learning how to interpret these images, you can quickly identify the required components and their relationships, making the repair process more efficient and accurate.

Identifying Key Components

The first step in reading a reference guide is recognizing the major parts outlined in the diagram. Each component will typically be labeled with a part number or name, often accompanied by a description of its function. Pay close attention to the visual details, as these will help you locate the correct area of the machinery where each element is situated.

Understanding Connections and Relations

In addition to individual parts, the diagram will show how components are connected or interact. Lines or arrows may indicate where pieces are fastened together or how they move in relation to one another. These connections are crucial for understanding how the machine operates and can help you pinpoint where a malfunction might occur.

Common County Line Tiller Repairs

Over time, even the most reliable gardening equipment may require attention due to wear and tear. Certain issues tend to be more common than others and can be addressed with some basic knowledge and tools. Understanding these frequent problems and how to resolve them is essential for keeping your machine running smoothly and avoiding costly repairs.

One of the most common issues is a malfunctioning engine, often caused by clogged filters, old fuel, or spark plug issues. Regular maintenance, such as cleaning the air filter and replacing spark plugs, can prevent these problems. Another frequent repair involves the transmission, which can suffer from worn gears or a lack of lubrication. Checking the transmission regularly and ensuring it is properly lubricated can prolong its life.

Another area that often requires attention is the cutting mechanism. Blades may become dull or damaged, reducing the machine’s efficiency. Regularly inspecting the cutting tools and replacing or sharpening them when necessary will ensure the equipment performs at its best. In addition, belt tension is another area that may need adjustment to prevent slipping or breakage during operation.