Proper maintenance and repairs of your outdoor machinery require a solid understanding of its individual elements. Knowing the function and location of each component is essential for effective troubleshooting and replacement. A clear breakdown of these parts allows for more efficient management of your machine’s performance.

Whether you’re a seasoned user or new to handling outdoor tools, understanding how each piece fits together is crucial. Familiarizing yourself with the layout and structure of your equipment not only aids in quick fixes but also ensures longevity. Accurate identification can prevent unnecessary replacements and enhance the overall functionality of your device.

In this guide, we’ll provide an in-depth look at the various sections and features that make up your machine. With clear explanations and visual references, you’ll gain the knowledge needed to address any issues that may arise. By the end, you’ll feel confident in managing repairs and optimizations independently.

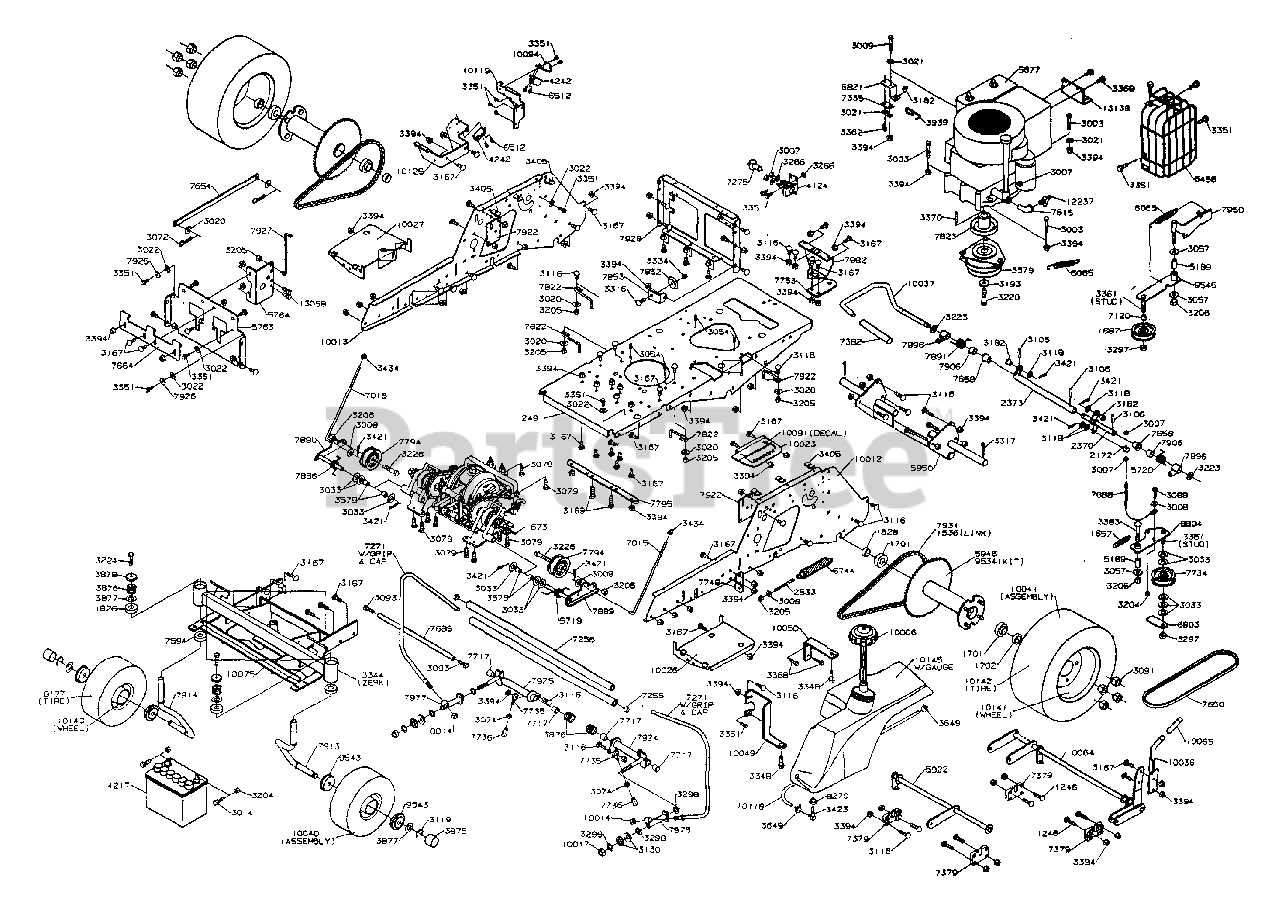

Dixon Mower Parts Overview

Understanding the key components of your lawn equipment is essential for ensuring its optimal operation. Each element plays a vital role in its overall performance and longevity. From the engine to the wheels, every part is designed to work in harmony to provide a smooth and efficient experience when maintaining your yard. Recognizing these components allows for better care, quick repairs, and improved functionality over time.

Main Functional Elements

The central pieces of any lawn tool are typically the engine, transmission, and cutting system. These components are the driving force behind the machine’s power and precision. The engine is responsible for generating the power needed to operate, while the transmission ensures that energy is directed efficiently to the wheels and cutting mechanism. Understanding how these elements interact will help you identify potential issues early, making repairs more straightforward and reducing downtime.

Additional Support and Control Mechanisms

In addition to the core mechanical components, various support elements like belts, filters, and handles are crucial for smooth operation. These parts may seem minor, but they greatly influence comfort, safety, and the overall user experience. Regular inspection of these elements ensures that the equipment runs without disruptions, preventing breakdowns and increasing reliability. By maintaining each section properly, you can maximize the life of your tool and improve its efficiency in performing tasks.

Identifying Key Components of Your Mower

Understanding the essential elements of your outdoor equipment is critical for effective maintenance and troubleshooting. Recognizing each part’s role allows you to manage repairs and keep everything running smoothly. Proper identification helps ensure that you can address specific issues without unnecessary delays and avoid costly mistakes in the process.

Core Functional Parts

The most important components of your tool include the engine, cutting mechanism, and wheels. The engine is the heart of the equipment, providing the necessary power for movement and operation. The cutting system is responsible for achieving the desired results during use, while the wheels provide mobility and support. Being familiar with these primary elements ensures that you can spot any issues related to power, movement, or cutting effectiveness quickly.

Supportive Features for Optimal Operation

Aside from the core elements, additional parts such as belts, filters, and handles contribute significantly to the functionality and comfort of your equipment. Belts are often responsible for transferring energy to the cutting system or wheels, while filters help maintain engine efficiency. Handles, although seemingly simple, provide vital control and stability during use. Regularly inspecting these auxiliary components can prevent unexpected malfunctions and ensure the machine operates at its best.

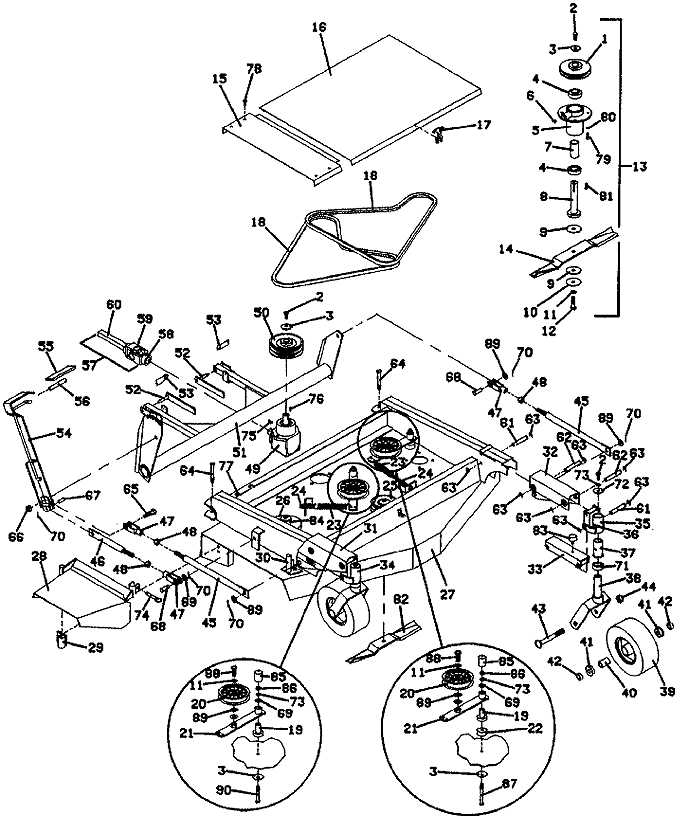

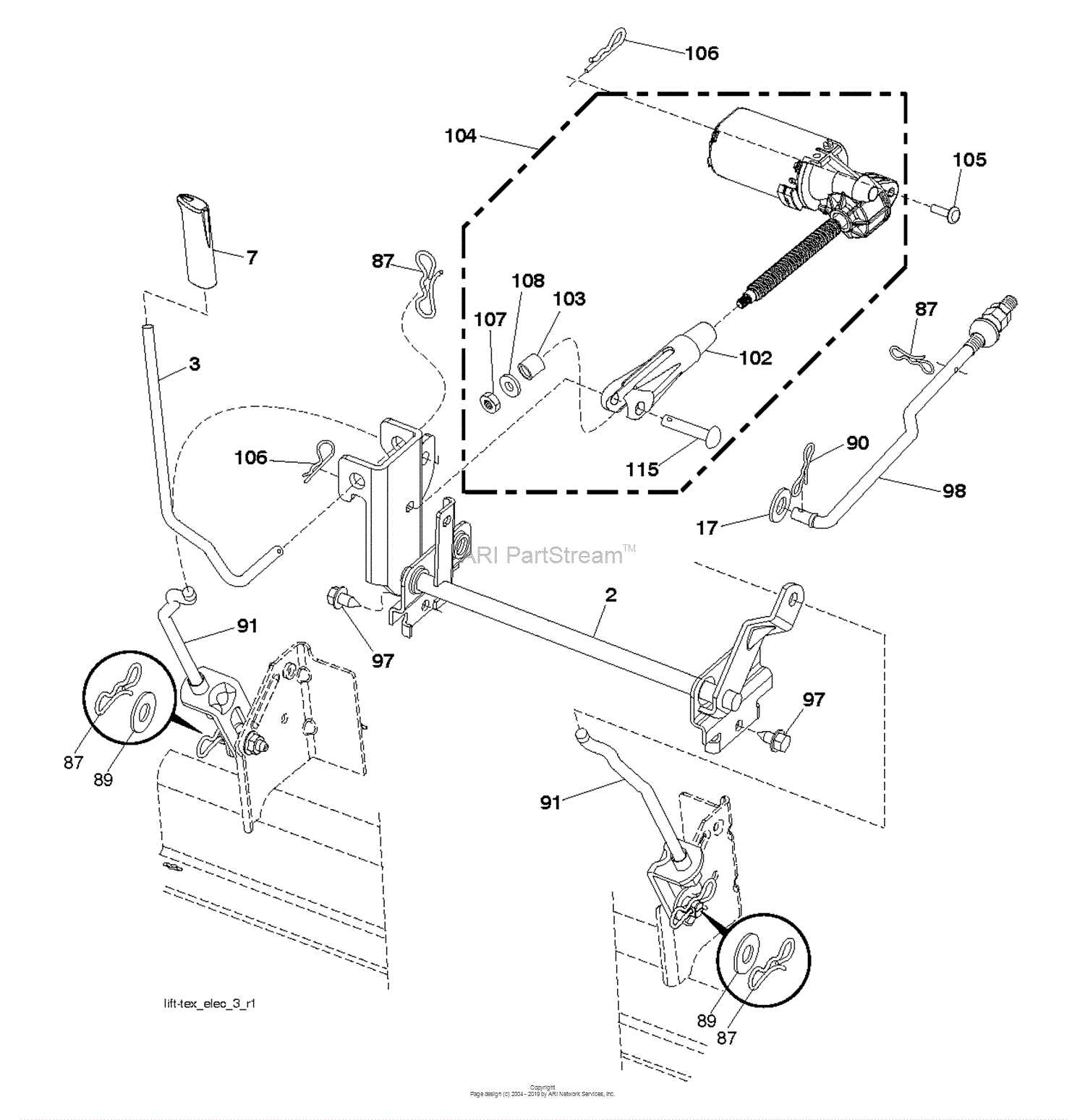

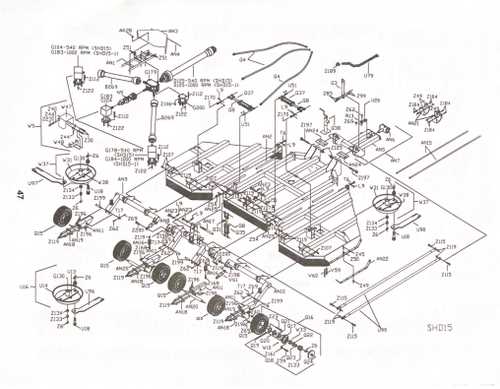

Step-by-Step Guide to Understanding Diagrams

Learning how to interpret visual representations of your equipment’s structure can significantly simplify maintenance and repair tasks. By breaking down complex illustrations, you can pinpoint each element and its relationship to the rest of the system. These visuals are designed to provide clarity, making it easier to understand how different parts interact and what needs attention during repairs or upgrades.

Breaking Down the Visuals

Start by identifying the main components shown in the illustration. Typically, these will include the most essential pieces such as the engine, cutting blades, and control mechanisms. Once you have these key elements in view, focus on how they connect to each other. Understanding the layout of the entire system will allow you to quickly recognize where problems may arise and how to address them effectively.

Using the Diagram for Troubleshooting

When issues occur, a well-understood visual can be your best tool for diagnosing the problem. Locate the malfunctioning area on the chart and compare it with the equipment to check for discrepancies. By following the guide, you can ensure that each part is correctly aligned and functioning. This approach minimizes guesswork and makes repairs faster and more precise.