Proper maintenance of garden machinery requires a clear understanding of its internal structure and functionality. Identifying and knowing the role of each individual element ensures that you can keep your equipment in optimal working condition for longer periods of time. Without this knowledge, it becomes difficult to address mechanical issues effectively.

Detailed visual representations of these systems are essential for anyone working with machinery. They help break down complex mechanisms into understandable parts, making it easier to locate and replace specific components. Such references simplify troubleshooting, repairs, and part replacements for those with varying levels of experience.

Knowing how each element interacts with the rest of the machine is crucial for maintaining its overall efficiency. By understanding the functions of different components, you can better manage your machine’s performance and prevent unnecessary wear or damage. Regular checks and attention to these elements not only enhance its longevity but also contribute to better productivity during use.

Tuff Torq K55 Parts Breakdown

Understanding the internal layout of mechanical systems is essential for proper maintenance and efficient operation. When dealing with complex machinery, it’s helpful to break down the entire structure into its core components. This approach not only makes troubleshooting easier but also assists in identifying parts that may need replacement over time.

Key Elements and Their Functions

The functionality of each element within the machine directly impacts its overall performance. Each component serves a specific purpose, working together to ensure smooth operation. Regular maintenance of these elements can prevent breakdowns and extend the lifespan of the equipment.

Component List Overview

The following table provides a detailed breakdown of the essential elements that make up the system, helping you understand the role of each part:

| Component | Function |

|---|---|

| Transmission Housing | Encases internal mechanical parts, providing protection and stability |

| Drive Shaft | Transmits rotational power from the engine to the drive system |

| Clutch Mechanism | Engages and disengages the power between the engine and wheels |

| Bearings | Facilitate smooth rotation of moving parts, reducing friction |

| Seals | Prevent fluid leakage and keep contaminants out of critical areas |

By examining these key components, one can better understand the operation of the system and identify areas for maintenance or repair. Each part plays an integral role in ensuring the machinery operates effectively and reliably. Regular inspection of these components is crucial for maintaining long-term performance.

Understanding the Key Components

Every complex machine consists of several critical elements, each with a distinct role in the overall function of the system. To maintain optimal performance, it’s essential to understand the specific function of each component. Recognizing how these parts interact allows for easier troubleshooting and efficient repairs when necessary.

Crucial Elements of the System

The essential parts of the machine work together to ensure smooth operation. These components range from structural elements that provide stability to moving parts that facilitate power transmission. Understanding their individual contributions will help improve machine longevity and prevent unnecessary damage.

Interconnection of Components

The interaction between each part is fundamental to the machine’s performance. For example, the drive components are interconnected with the control system, allowing seamless power transfer while maintaining operational efficiency. A disruption in any key component can affect the entire system’s reliability.

How to Identify Key Components

Identifying the various components within a mechanical system is crucial for effective maintenance and repair. Recognizing each element helps to ensure that troubleshooting and part replacement are done accurately and efficiently. Proper identification also prevents errors during reassembly and ensures the system remains operational.

Visual Identification Techniques

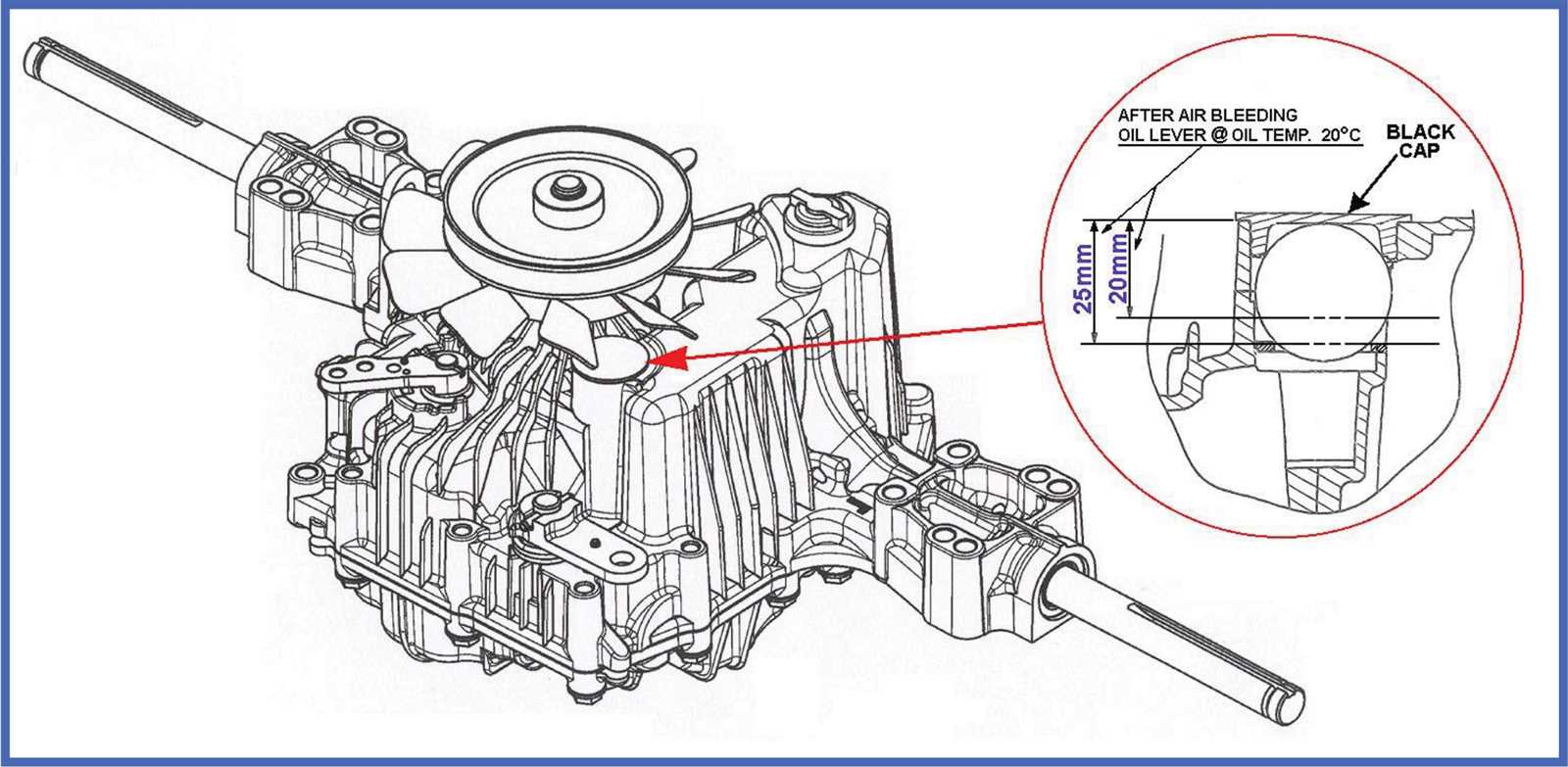

One of the easiest ways to identify key components is through visual inspection. Many parts have distinct shapes, sizes, or markings that differentiate them from others. Pay attention to labels, color codes, and the arrangement of components, as these can provide important clues regarding their function and placement within the system.

Using Reference Materials

In addition to visual inspection, reference guides and manuals are excellent resources for identifying components. Diagrams, photos, and written descriptions can help you locate and understand the purpose of each part. Using these materials during maintenance or repair tasks will ensure the correct components are handled appropriately.

Visual Guide to Component Locations

Accurate identification of where each part is located within a mechanical system is crucial for efficient repairs and maintenance. A clear visual guide helps users navigate through the equipment and easily find components that need attention. This approach reduces the time spent searching and ensures that the right elements are serviced when required.

Locating Key Components

Each part is strategically placed to optimize performance and ease of access. By understanding the layout of these elements, you can quickly locate and troubleshoot any issues. Below is a list of common locations for major components:

- Power Transmission Area: Often located near the central housing, responsible for delivering power to various moving parts.

- Drive Mechanism: Typically positioned near the output shaft, connecting the engine to the wheels or other driven parts.

- Control System: Usually found near the operator’s station or central panel, managing the flow of energy throughout the system.

- Seals and Gaskets: Positioned around critical connections to prevent leaks and keep contaminants out of sensitive areas.

Helpful Tips for Navigating the System

When navigating through the machinery, pay attention to the following:

- Color Coding: Some systems use color codes to differentiate between various lines or parts, making identification easier.

- Part Numbers: Many components will have part numbers engraved or printed on them, which can assist in both identification and replacement.

- Shape and Size: The physical size and shape of components often provide immediate clues to their function and position.

Maintenance Tips for Tuff Torq K55

Proper maintenance is essential for ensuring the longevity and optimal performance of mechanical systems. Regular care and attention to specific areas help avoid breakdowns and costly repairs. By following a few straightforward maintenance tips, you can keep the equipment running smoothly and efficiently over time.

Regular Cleaning

Cleaning the components regularly helps prevent dirt and debris from building up, which could cause parts to malfunction. Use a soft brush or compressed air to clear dirt from hard-to-reach areas, ensuring that no grime accumulates in sensitive parts such as seals or bearings.

Lubrication and Fluid Checks

Regularly lubricating moving parts and checking the fluid levels are crucial tasks for maintaining proper functioning. Make sure to use the recommended lubricant and fluids for your system, as using the wrong types can lead to wear or damage. Always check fluid levels, and top them off as needed to ensure smooth operation.

Inspecting for Wear and Tear

Inspecting the system for signs of wear is essential to catch potential issues early. Focus on areas like the drive components and seals, as these parts tend to experience the most strain. If you notice any irregularities such as leaks, unusual noises, or reduced performance, it’s time to address the issue before it worsens.