Maintaining and repairing agricultural machinery requires a clear understanding of its individual elements. This knowledge is essential for anyone looking to optimize the performance and lifespan of their equipment. With the right information, users can easily identify and address any issues that arise during use.

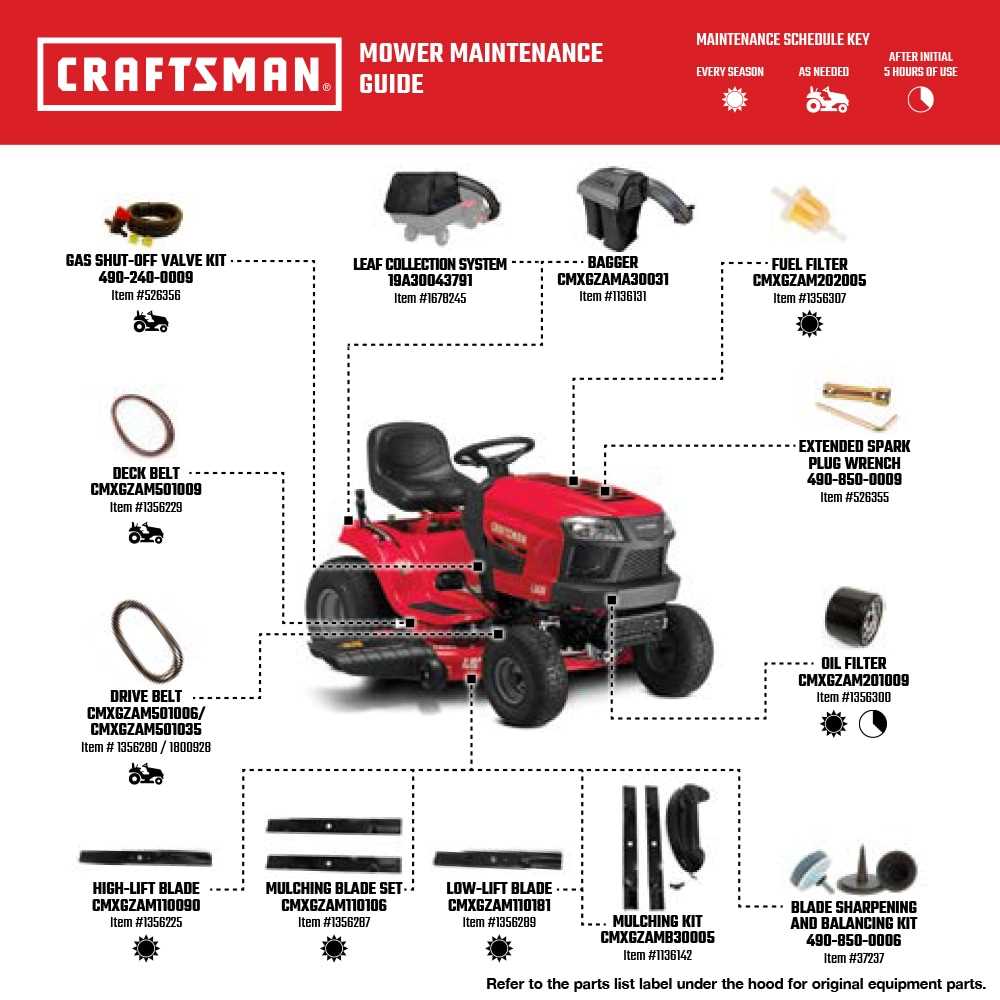

One of the key aspects of proper maintenance is being able to recognize the different components and their functions. Familiarizing yourself with these parts allows for better decision-making when it comes to repairs or upgrades. Accurate identification ensures that the right tools and components are used, preventing unnecessary downtime.

Whether you’re troubleshooting a malfunction or performing routine maintenance, knowing the layout and relationships between each component is crucial. By following a structured guide, users can gain confidence in their ability to address any concerns and keep machinery operating efficiently.

Understanding Agricultural Equipment Components

In the realm of farming machinery, a deep knowledge of its individual elements is vital for efficient operation and long-term reliability. Every machine consists of various interconnected components that work together to ensure optimal performance. Understanding how these parts interact helps users make informed decisions during repairs and maintenance, reducing the risk of malfunctions and enhancing overall efficiency.

Key Functional Units

Farming machinery includes a range of functional units designed to perform specific tasks. Each unit plays a crucial role in the overall operation, whether it’s for cutting, transportation, or adjustment. Recognizing these distinct elements enables users to pinpoint issues more effectively and make precise repairs when necessary. A thorough grasp of each unit’s role within the system improves both troubleshooting and preventive measures.

Maintenance Considerations

Regular upkeep of machinery requires knowledge of the components that are most prone to wear and tear. Focusing on these critical areas can prevent unexpected failures and keep the equipment running smoothly for longer periods. A proper understanding of how to access, replace, and maintain these components ensures that the machinery remains in top condition, reducing the need for costly repairs and downtime.

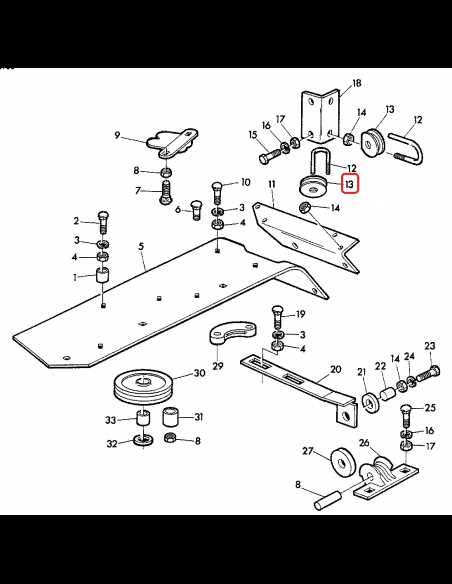

Identifying Key Parts in the Diagram

To effectively manage and repair any piece of farming equipment, it’s essential to understand the critical components and their specific functions. A well-structured guide provides clarity on how each part contributes to the machine’s overall performance. By identifying these key elements, users can address issues more efficiently and perform necessary repairs with confidence.

Recognizing essential components begins with knowing their placement within the system. The layout helps users identify which parts need attention during maintenance. Each component, from cutting mechanisms to support structures, plays an important role in ensuring smooth operation. Understanding these relationships helps avoid confusion when addressing mechanical failures or performing upgrades.

Clear identification also enables operators to understand how to disassemble and reassemble the equipment correctly. This ensures that each part is properly reinstalled and securely fastened, which is crucial for safe and effective operation. Recognizing these key components is not only vital for repair but also for understanding how to maximize the equipment’s efficiency.

Importance of Accurate Equipment Component Selection

Choosing the right components for agricultural machinery is crucial for its performance and longevity. Selecting the appropriate parts ensures that the system functions optimally and reduces the likelihood of malfunctions. With numerous options available, accuracy in part selection not only guarantees compatibility but also prevents the need for costly repairs and extended downtime.

Ensuring Compatibility and Efficiency

Properly matched components contribute to smoother operation, ensuring that each element works in harmony with others. When parts are chosen based on correct specifications, efficiency is maximized, and energy consumption is minimized. This ultimately leads to better fuel economy and less wear on the machinery, extending its useful life.

Reducing Maintenance Costs

Incorrectly selected components can lead to frequent breakdowns and more expensive repairs. By opting for parts that are specifically designed for the equipment, the risk of unexpected failures is greatly reduced. This proactive approach helps farmers save on long-term maintenance expenses while enhancing overall productivity.

Choosing the Right Components for Repairs

When repairing agricultural machinery, selecting the correct elements is key to ensuring the repair is successful and the equipment remains functional for the long term. The right choice minimizes the risk of further damage and guarantees that the machinery operates at peak efficiency. Proper component selection prevents unnecessary issues and maintains the equipment’s reliability.

Identifying the Correct Specifications

Each component has specific requirements that must be matched to the machine’s design. It’s essential to know the exact specifications, such as size, material, and functionality, to ensure the part is compatible. Using the correct specification ensures that the new component fits properly, avoiding misalignments or malfunctions.

Quality Considerations

Choosing high-quality components is equally important as matching the specifications. Durability and material strength play a significant role in the repair’s success. Opting for high-quality replacements can significantly extend the lifespan of the machinery, reducing the need for future repairs and ensuring the system operates smoothly over time.

Step-by-Step Equipment Assembly Guide

Assembling complex agricultural machinery requires precision and a clear understanding of each step. Following a structured assembly process ensures that every component is correctly installed, which is essential for the machine’s overall performance and safety. By breaking down the assembly into manageable tasks, users can avoid mistakes and ensure the equipment functions as intended.

Before starting, gather all the necessary tools and components. Having everything in place ensures that the assembly process goes smoothly without delays.

- Prepare the Frame: Start by setting up the main framework of the machine, ensuring all bolts and supports are aligned. This will serve as the base for further assembly.

- Attach the Supporting Structures: Securely fasten the essential support structures to the frame. These elements provide stability and ensure proper functionality during operation.

- Install the Cutting Mechanisms: Position and connect the cutting components, ensuring they are securely attached and properly aligned. Double-check the positioning for correct movement.

- Set up Adjustment Features: Install the necessary adjustment mechanisms that control the machine’s performance. Test their movement to confirm proper functionality.

- Final Inspection: Once all components are assembled, conduct a thorough inspection to ensure that everything is properly installed and there are no loose parts. Tighten all bolts and connections as necessary.

By following these steps, the assembly process becomes more efficient, reducing errors and ensuring that the equipment operates at its full potential.