Proper maintenance is essential to ensure the longevity and optimal performance of your lawn machinery. With so many components working together, it’s crucial to have a clear understanding of how each part functions and how to replace or repair them when necessary. Whether you’re a seasoned professional or a beginner, knowing the structure of your equipment can save you time and effort in the long run.

Identifying the right components for replacement or repair is often the first step in the maintenance process. A visual guide can help you pinpoint the exact parts that need attention, making the job simpler and more efficient. Recognizing the individual elements of your machine allows you to act quickly, avoiding unnecessary delays or mistakes.

When facing common issues or breakdowns, having a clear understanding of how everything fits together can make troubleshooting a lot easier. By focusing on the necessary elements and using reliable resources, you can confidently address problems and restore your equipment to peak condition.

Understanding Your Lawn Equipment Components

When it comes to maintaining your lawn equipment, a solid understanding of its various components is crucial for smooth operation. Each part plays a specific role, and knowing how they interact can help with both regular upkeep and more advanced repairs. Whether you’re working with the engine, transmission, or other mechanisms, having a comprehensive view of the machine’s structure is essential for successful maintenance.

Familiarizing yourself with these key elements enables you to identify which components need attention. This knowledge allows you to quickly pinpoint worn-out or broken pieces, ensuring your equipment remains in working order. Understanding how everything fits together not only simplifies repairs but also helps in choosing the correct replacements when needed.

In this section, we will explore the various features of your machine, focusing on how each element contributes to the overall functionality. By breaking down the main components and their roles, you will gain a clearer understanding of how to manage and repair your equipment efficiently.

How to Use the Visual Guide

Having a visual reference for your equipment can greatly simplify the process of identifying individual components. By studying a detailed illustration, you can easily locate the specific parts you need to repair or replace. Understanding how to use this guide effectively is key to performing tasks with precision and efficiency.

To make the most of the reference, follow these steps:

- Identify the section: Start by locating the area related to the issue you’re addressing. Each section is typically grouped by function, such as the engine or transmission.

- Locate individual components: Within each section, find the components that require attention. The guide will label each part with a unique identifier or number.

- Understand the relationships: Pay attention to how the components interact with each other. This will help you understand which parts need to be removed or replaced in the process.

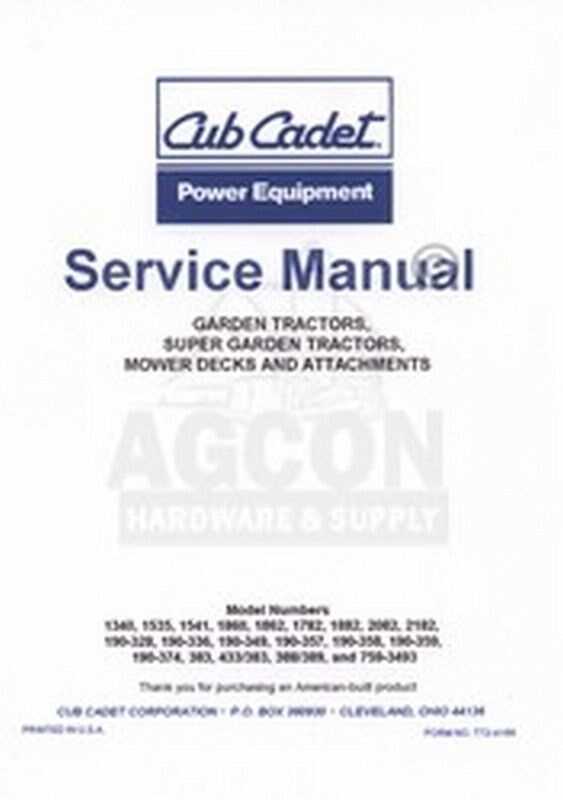

- Cross-reference with the manual: For further clarity, refer to the equipment manual to verify part numbers and detailed descriptions.

By following these steps, you can effectively use the visual reference to navigate the complexities of your machine, making repairs and maintenance much more manageable.

Common Issues and Replacement Components

Every piece of machinery is prone to certain issues over time, and knowing which parts are most likely to fail can save you time and frustration. Whether it’s the engine, transmission, or other vital systems, common wear-and-tear problems can affect performance. Recognizing these issues early allows you to address them promptly and minimize downtime.

Some of the most frequent problems include:

- Engine difficulties: Overheating or starting issues may arise due to faulty spark plugs, fuel filters, or air filters.

- Transmission problems: Slipping gears or unresponsive shifting can often be traced back to worn-out belts or damaged linkages.

- Battery issues: A weak or dead battery can hinder performance and prevent the equipment from starting. Replacing the battery is often the best solution.

- Worn blades or wheels: Dull blades or damaged wheels can affect cutting efficiency and movement, requiring replacement for optimal operation.

When these issues occur, it’s essential to identify the correct replacement components to restore your machine’s functionality. Using a detailed visual reference can help you locate and order the necessary items, ensuring a smoother repair process and extending the life of your equipment.