Maintaining and repairing outdoor machinery requires a deep understanding of its individual components. These machines are designed to make yard work more efficient, and knowing how each part functions and fits together is essential for both regular maintenance and troubleshooting. In this section, we will explore the critical elements of these machines, focusing on their structure and function.

Every part plays a specific role in the overall operation of the system. From the engine mechanisms to the moving blades, each piece works in harmony to ensure optimal performance. Proper identification and understanding of these elements can help with diagnosing issues, performing repairs, and ensuring that everything runs smoothly.

Knowing the layout and specific parts not only makes repair tasks more manageable but also extends the lifespan of the equipment. This section aims to offer a clearer picture of how everything is assembled, providing you with the tools to care for your machinery properly.

Key Elements of Lawn Care Machinery

The efficiency of outdoor equipment depends on how well its individual elements are designed and maintained. Each part plays a crucial role in the overall performance, contributing to the machine’s ability to function smoothly. Understanding the essential components of these systems allows for better maintenance, repair, and troubleshooting.

Critical Components and Their Functions

At the heart of these machines, several key elements work together to ensure precise operation. From the main housing that supports the structure to the moving mechanisms that carry out tasks, every component has a specific purpose. Understanding these elements allows users to identify potential issues and take appropriate action when needed.

Assembly and Interaction of Components

The interaction between different parts is vital for the smooth operation of the machinery. Each component fits together in a precise manner, contributing to the overall efficiency. When these elements are correctly maintained and replaced as necessary, the entire system operates at its best, ensuring long-term durability and effectiveness.

Detailed Breakdown of Components

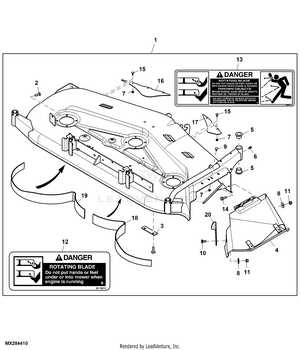

Each machine consists of various elements that work in unison to achieve optimal functionality. Understanding the structure and role of each individual part is crucial for proper operation, maintenance, and repair. This section will examine the key components, their roles, and how they interact to ensure the equipment runs smoothly.

The central unit typically houses the primary mechanisms that control movement and provide the necessary power. Surrounding this are several key components, such as the rotating blades, transmission systems, and adjustment mechanisms, all of which must work together seamlessly. Understanding their individual functions makes it easier to diagnose problems and replace worn or damaged pieces.

In addition to the moving parts, there are several fixed elements that provide structural support and stability to the system. These components, though stationary, are integral to the overall function and ensure the machine operates with precision and balance.

Proper Care for Optimal Performance

To ensure that your outdoor machinery continues to perform efficiently, regular maintenance is essential. Taking proactive steps to inspect and service the machine will help prevent costly repairs and extend its lifespan. In this section, we will focus on key maintenance practices that can enhance the longevity and functionality of your equipment.

Routine Inspection and Cleaning

One of the most important aspects of upkeep is conducting regular checks on the equipment. Inspect the moving parts, check for signs of wear, and clean any accumulated debris. This helps prevent clogging and keeps everything running smoothly. Regular cleaning also reduces the risk of rust and corrosion, which can damage the machinery over time.

Lubrication and Adjustments

Lubricating the moving components ensures that friction is minimized, reducing the chances of breakdowns. Regularly check for necessary adjustments, such as tension on belts or alignment of the blades, to ensure optimal performance. A well-lubricated and finely-tuned machine operates more efficiently and lasts longer, minimizing downtime and maintenance costs.

Extending the Life of Your Gear

Taking steps to preserve the functionality of your machinery not only ensures long-term performance but also minimizes the cost of repairs. With proper care, many pieces of equipment can function optimally for years, reducing the need for frequent replacements. This section outlines effective strategies to enhance the durability and reliability of your outdoor tools.

Regular Cleaning and Storage

Keeping your equipment clean and properly stored is one of the most effective ways to extend its lifespan. After each use, ensure that debris is cleared from critical parts. Additionally, when not in use, store your tools in a dry, sheltered environment to protect them from the elements.

Proper Usage and Adjustments

Using your machinery according to the manufacturer’s recommendations can prevent unnecessary wear. Make sure that adjustments, such as tensioning or alignment, are made regularly to ensure that all parts operate smoothly. Overuse or misuse can lead to accelerated damage, so operating within recommended limits is key to longevity.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Clean and inspect components | After each use | Prevents debris buildup and rust |

| Lubricate moving parts | Every few uses | Reduces friction and wear |

| Check alignment and tension | Monthly | Ensures optimal operation |

Replacing worn or damaged components of your outdoor equipment is a necessary task to maintain its performance and extend its lifespan. The replacement process involves several steps, from identifying the faulty parts to installing the new components. In this section, we will walk through the essential steps for successfully replacing critical elements of your machinery.

Steps for Replacing Key Components

Before beginning, ensure you have the correct replacement parts and the necessary tools. Follow these general steps to replace the damaged pieces:

- Turn off the equipment and disconnect the power source for safety.

- Remove any covering or housing that obstructs access to the components needing replacement.

- Carefully disconnect and remove the damaged part using the appropriate tools.

- Install the new component, ensuring it is properly aligned and securely attached.

- Reassemble the housing or covering and perform a thorough inspection before use.

Important Considerations

During the replacement process, make sure to pay attention to the following factors:

- Ensure all new parts match the specifications of the original equipment to avoid compatibility issues.

- Take extra care with fragile components, especially when removing or installing them.

- Check all connections for tightness and security after installation to avoid potential malfunctions.

Step-by-Step Replacement Guide

Replacing essential components of your outdoor equipment may seem like a daunting task, but with the right approach, it can be a straightforward process. This guide provides a clear, step-by-step breakdown to help you complete the replacement with ease, ensuring that your equipment continues to function at its best.

Preparation Before Replacing Parts

Before starting the replacement process, it’s important to gather the necessary tools and ensure that you have the correct replacement components. Follow these preparatory steps:

- Turn off the equipment and disconnect any power sources.

- Collect all tools required for disassembly, such as wrenches, screwdrivers, and pliers.

- Identify the faulty component that needs replacing and ensure you have a compatible replacement part.

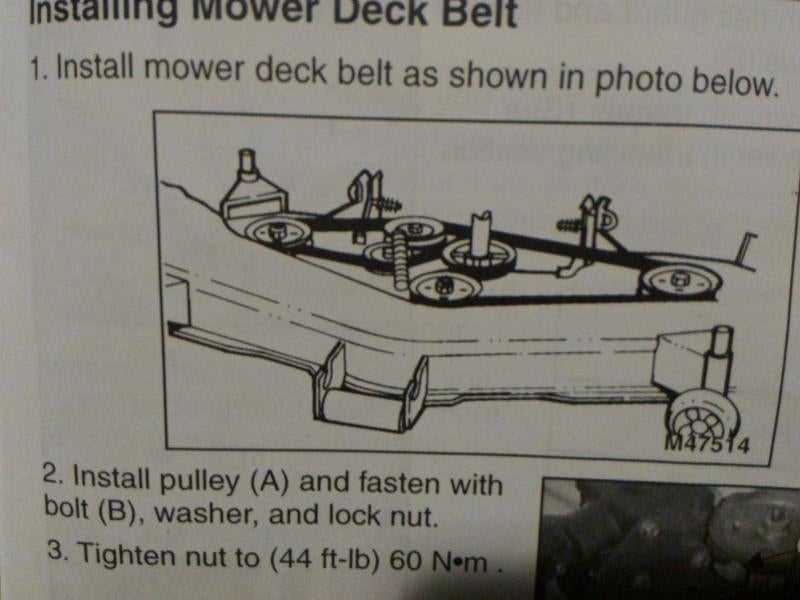

Replacement Process

Now that you’re ready to begin, follow this step-by-step guide to replace the damaged part:

- Carefully remove any coverings or guards blocking access to the faulty component.

- Loosen and remove fasteners or bolts securing the part in place.

- Remove the damaged component and inspect surrounding areas for any further issues.

- Install the new component, ensuring it is aligned and secured properly with bolts or fasteners.

- Reassemble any housing or protective covers and ensure everything is tightly fastened before testing.