A deep understanding of the key components that drive agricultural machinery is crucial for effective operation and maintenance. When working with harvesters, knowledge of the various elements involved ensures optimal performance during peak seasons. The intricate design and function of these machines are tailored to meet the demanding needs of modern farming.

Within these complex systems, each part plays a specific role, contributing to the smooth functioning of the entire mechanism. Recognizing how each component interacts allows operators to troubleshoot effectively, prolong the life of the equipment, and avoid unnecessary breakdowns.

In this section, we will break down the essential elements and their functions, providing valuable insights into the design and assembly of such machinery. By understanding these fundamental aspects, you will be better equipped to manage maintenance tasks and keep your equipment running efficiently.

Understanding the New Idea Corn Picker

Harvesting equipment plays a vital role in modern agriculture, providing farmers with the necessary tools to increase efficiency during harvesting seasons. A closer look at these machines reveals their sophisticated designs, where every component serves a specific function to ensure smooth operation. Proper understanding of their structure is key to achieving the best results when using such machinery.

How the Machine Functions

At its core, the machine is designed to streamline the harvesting process. It integrates several mechanisms that work in harmony, from the intake system to the final collection. Each part contributes to moving the crops from the field to storage with minimal loss and maximum efficiency. Operators who understand the intricate workings of these machines can ensure they perform optimally under various conditions.

Key Features of the Equipment

There are essential features that set this harvester apart from others. Its ability to adjust to different environments, combined with the design of its components, makes it versatile and reliable for various types of harvest. Regular maintenance and understanding the role of each element within the system can significantly reduce downtime and improve overall functionality, making this equipment a valuable asset for any farm operation.

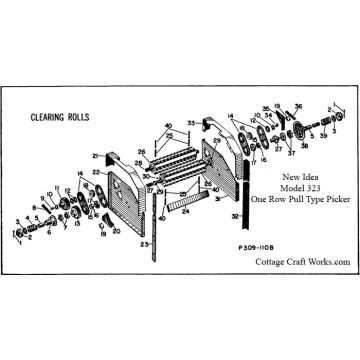

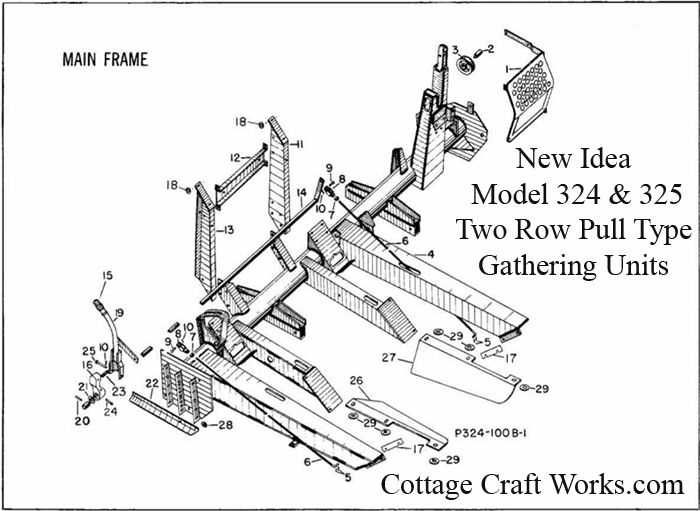

Key Components of the Corn Picker

Every agricultural machine designed for harvesting consists of several integral components that collaborate to improve efficiency and reduce labor. These elements are carefully engineered to handle various tasks, from collecting crops to transporting them to storage. Understanding these core components helps users maximize the machine’s performance and reduce wear over time.

Collection and Separation Mechanisms

One of the primary functions of this equipment is to gather and separate crops from the field. The collection mechanism includes intake rollers and feed augers, which work together to pull in the crops and move them toward the separation system. The separator bars or vibrating components ensure that the plants are properly handled, ensuring minimal loss and optimal productivity.

Transport and Storage Systems

Once the crops have been collected, they must be transferred to a storage container for further processing. The transport system, typically made up of conveyor belts or elevators, moves the harvested materials efficiently. This system is designed to handle large volumes while preventing damage to the crop, ensuring that the harvested material reaches the storage unit without unnecessary delays.

How the Parts Work Together

In any agricultural machine, the efficiency and effectiveness of the entire system depend on how the individual elements function in harmony. Each component is designed to support and enhance the others, ensuring that the machine operates smoothly and achieves its intended purpose. The key to success lies in the seamless interaction between these mechanisms, which enables the machine to perform optimally under various conditions.

Coordinated Functionality

The process begins with the intake system, where crops are drawn into the machine. As the material enters, it is transferred via feed rollers to the separation system, which isolates the useful crop from other debris. The synchronized motion between these elements ensures that each step in the process is carried out efficiently and with minimal interruption. The entire operation, from gathering to processing, works together to maintain a constant flow and high output.

Effective Transfer and Storage

Once the crops have been separated, the conveyor systems and elevators take over, moving the harvest to its final destination. This transition between collection, separation, and storage requires precise coordination to prevent overloading or damaging the harvest. By ensuring that each component is in perfect alignment, the machine can handle large volumes without slowing down or losing efficiency. This collaboration is what makes the system so reliable and effective in large-scale agricultural operations.