Proper maintenance is essential for ensuring the long-lasting performance of outdoor machinery. Identifying each component and understanding its function can greatly improve the effectiveness of repairs and adjustments. In this section, we will explore the essential elements that contribute to smooth operation.

Familiarity with how various components work together allows for easier troubleshooting and proper care. Knowing the names and roles of individual pieces will make it simpler to identify potential issues before they become major problems.

By carefully reviewing a detailed breakdown of each section, owners can achieve better results, minimize downtime, and maintain peak performance for years to come. Whether you’re performing routine checks or tackling more complex fixes, this knowledge is invaluable.

Understanding Lawn Equipment

Maintaining outdoor machinery requires a solid understanding of its core components and how they function together to achieve optimal performance. A well-organized system of moving parts works in harmony to ensure that the equipment operates smoothly and efficiently. Having a clear understanding of this system is essential for troubleshooting and conducting proper maintenance.

Each element serves a specific purpose, from the mechanical pieces that handle motion to the smaller parts responsible for precision control. Recognizing how each part fits into the whole will allow for easier identification of issues, as well as more accurate adjustments and repairs.

Being familiar with the structure and operation of the machine makes it easier to keep everything in working order, ensuring that it can handle tasks effectively for years. This knowledge not only simplifies maintenance but also extends the lifespan of the equipment by preventing unnecessary wear and tear.

Essential Elements of the Lawn Equipment

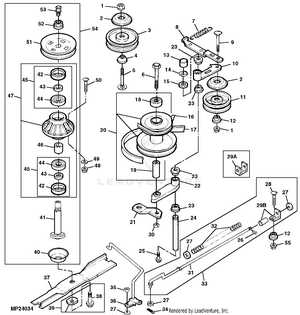

The heart of any outdoor machine lies in its critical components, each contributing to the overall function and efficiency of the system. Every part has a unique role, from ensuring smooth movement to providing the necessary precision for the task at hand. Understanding the key elements is crucial for maintaining optimal performance and durability.

The main components that drive the system are typically responsible for motion, control, and cutting functions. They work together seamlessly, with each piece carefully designed to withstand the pressures of regular use while offering the needed durability for long-term effectiveness.

By focusing on the most important elements, users can identify wear and tear early, making it easier to perform preventive maintenance and keep the machinery operating at peak levels for an extended period of time.

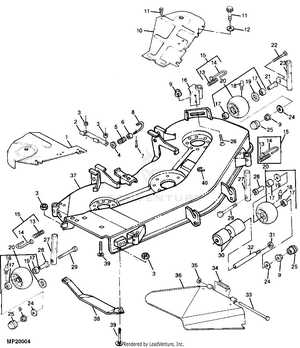

How to Read the Components Layout

Interpreting the layout of mechanical elements can seem daunting at first, but understanding the symbols and annotations used in these diagrams makes the process much easier. Each representation provides a visual guide that outlines the arrangement and relationship between various parts of the system, allowing for a better understanding of how everything fits together.

Key to reading these diagrams is recognizing the specific symbols that correspond to each component. These diagrams typically use simple lines, numbers, and labels to identify parts, as well as show their placement and connection points. Familiarizing yourself with these visual cues is the first step in effectively utilizing the layout for repairs or maintenance.

Once you become familiar with the layout conventions, you’ll find it much simpler to pinpoint issues, plan repairs, or assemble components correctly. The clarity offered by these diagrams can greatly enhance your ability to troubleshoot and maintain the machinery in the most efficient way possible.