Understanding the various components of agricultural machinery is crucial for maintaining its performance and ensuring its longevity. By familiarizing yourself with the key elements and how they work together, you can prevent common malfunctions and address issues more efficiently. This section provides a comprehensive breakdown of important parts and how to identify them within your equipment.

Properly interpreting technical schematics is an essential skill for anyone involved in equipment maintenance. These detailed visuals offer a clear overview of the machinery’s internal structure, allowing users to pinpoint specific components, their functions, and how to properly replace or repair them. Gaining proficiency in reading these diagrams empowers you to handle routine maintenance and unexpected repairs with confidence.

Whether you’re an experienced technician or a beginner, this guide will walk you through the various sections and provide practical advice on managing your machinery’s upkeep. With the right knowledge, you’ll be able to keep your equipment in top working condition for years to come.

Understanding Machine Components

Maintaining agricultural equipment requires a solid understanding of its core elements and how they function together to ensure optimal performance. By learning about the different sections of the machine, users can more easily troubleshoot problems, identify worn-out pieces, and prevent unnecessary breakdowns. This knowledge is essential for anyone involved in operating or servicing this type of machinery.

Key Elements of the Equipment

The main structure of the equipment is composed of several interconnected components, each with its specific role. These parts work in harmony to allow smooth operation, whether it’s for cutting, lifting, or adjusting. Having a clear understanding of each part’s function helps in pinpointing issues quickly and effectively. Regular inspection and maintenance of these elements are critical for extending the machine’s service life.

Common Issues and Solutions

Like all machinery, wear and tear on specific parts is inevitable over time. The most common issues typically involve the cutting system, drive components, or the adjustment mechanisms. Recognizing early signs of malfunction, such as abnormal vibrations or performance drops, can prevent costly repairs. Replacing worn components with the correct replacements ensures that the equipment stays functional and efficient for longer periods.

How to Read the Schematics

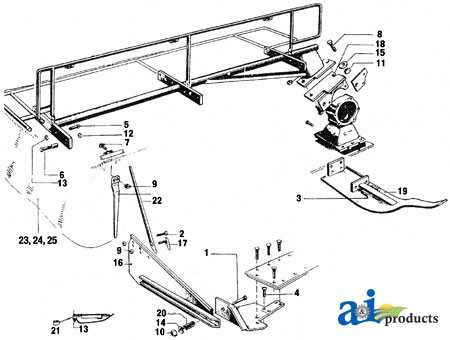

Understanding technical visuals is a fundamental skill when working with complex machinery. These schematics provide a clear and organized view of all the machine’s components and their interconnections. By interpreting these images correctly, you can identify each part and understand how they work together to ensure smooth functionality.

Identifying Key Components

Each section of the visual represents a specific group of parts, often arranged in a logical sequence. You’ll find components grouped by their function, such as cutting elements, drive mechanisms, and adjustment systems. The key to reading these schematics is recognizing how each part fits into the overall structure and how it contributes to the machine’s operation.

Understanding Labels and References

Most schematics include labels or reference numbers that link the components to a parts list. These labels are crucial for locating the right items when performing maintenance or repairs. It’s important to familiarize yourself with the numbering system and how parts are categorized to make the process more efficient.

Common Issues and Replacement Parts

Like all machinery, certain components experience wear over time, leading to common issues that can affect performance. Recognizing these signs early can help prevent more serious problems down the line. Regular maintenance and timely replacement of faulty elements ensure the equipment continues to run smoothly and efficiently.

One of the most frequent issues involves the cutting system, where blades may become dull or damaged, affecting their efficiency. In addition, drive components can wear out due to constant friction, leading to a decrease in power transmission. Properly identifying these issues early allows for quick replacements, minimizing downtime.

Other common concerns include worn-out belts or seals, which can cause poor performance or even equipment failure. When it comes to replacements, using high-quality, manufacturer-recommended components ensures the best results and longevity of the machinery. Understanding which parts are most likely to need replacement will help you stay ahead of potential malfunctions.