Proper maintenance of your lawn equipment is essential for its longevity and optimal performance. Each piece of machinery is made up of various components that work together to ensure smooth operation. By gaining a deeper understanding of these parts, owners can identify potential issues and address them before they become significant problems.

Having a clear overview of the essential elements involved helps in managing repairs and replacements efficiently. Recognizing how each part contributes to the overall functionality allows for better care and preservation of the equipment. This knowledge is not only beneficial for troubleshooting but also aids in enhancing the efficiency of the entire system.

Understanding the John Deere 54D Deck

The cutting system is an essential component of any lawn maintenance tool. It plays a critical role in achieving efficient and precise results when trimming grass. By combining innovative technology and durable design, this system ensures that the lawn is well-groomed and evenly maintained. Understanding how the system operates and how different elements work together can help in troubleshooting and maintaining performance over time.

This particular system is designed for versatility and ease of use. With its advanced features, it allows operators to quickly adjust settings and ensure optimal performance. Its construction is made from high-quality materials to withstand prolonged usage while maintaining excellent functionality. Regular maintenance and familiarity with its components will keep it running smoothly, providing lasting value for users.

The mechanism features a range of key components that are integrated seamlessly for user-friendly operation. With the proper care and maintenance, each part contributes to the overall effectiveness of the equipment, ensuring a smooth and consistent cutting experience. Whether for regular lawn care or more intensive yard work, understanding the system’s design helps in maximizing its performance and extending its lifespan.

Key Components of the Mower Deck

The system’s efficiency is largely determined by the interaction of its core elements. Each component has been designed to fulfill a specific function, contributing to the overall performance and durability of the machine. Understanding these key components allows operators to maintain the equipment better and resolve issues more effectively when they arise.

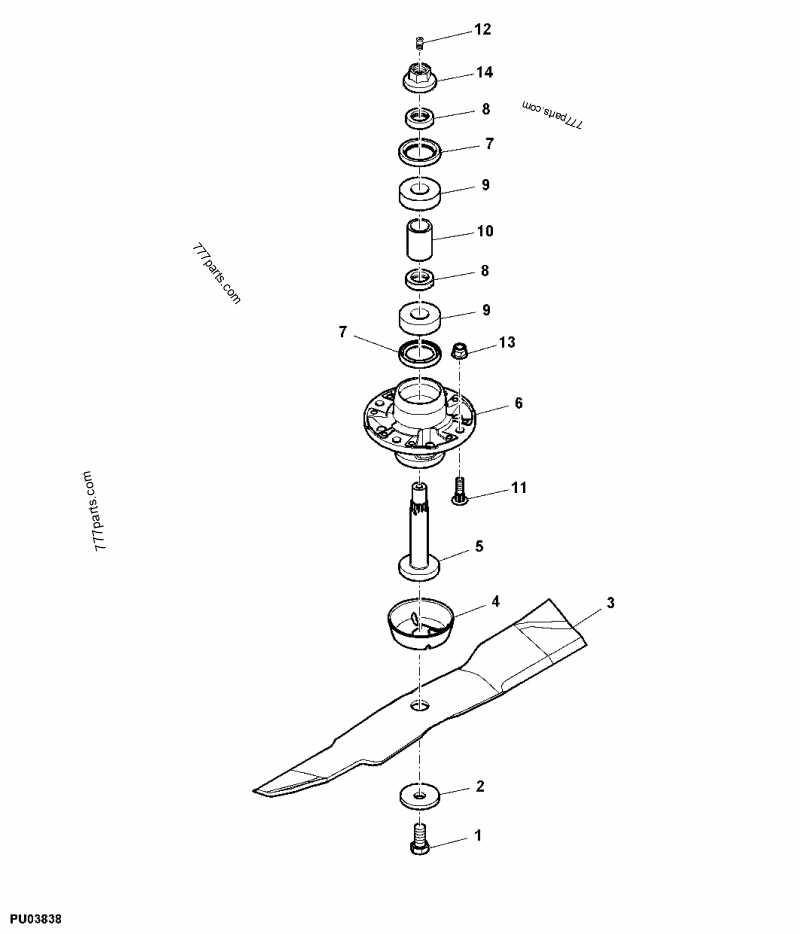

Blades and Spindles

The cutting blades are one of the most crucial elements of this system. They are engineered to deliver clean, precise cuts to ensure a well-maintained lawn. The spindles, which support the blades, are responsible for their smooth rotation and alignment. Ensuring that these parts are well-lubricated and free of debris is essential for optimal performance.

Belts and Pulley System

The belt and pulley assembly plays a critical role in transmitting power to the cutting blades. It works by converting the energy from the engine into rotational force that drives the blades. Regular inspection and maintenance of these components ensure that the system operates smoothly and prevents any unnecessary wear or breakdowns.

Maintaining Auto Connect System Efficiency

Ensuring optimal performance of the integrated connection system is crucial for consistent and efficient operation. Proper care and routine checks are necessary to keep the components working seamlessly together. Regular maintenance helps prevent premature wear, reduces the risk of breakdowns, and enhances the longevity of the entire system.

Regular Inspections are essential to identify any issues before they become serious problems. Check for any signs of wear or misalignment in the connections and components that are involved in the engagement and disengagement process. This simple step can save significant time and cost in the long run.

Cleaning and Lubrication play a key role in maintaining the system’s efficiency. Debris buildup can impair movement and cause friction, while a lack of lubrication can lead to unnecessary wear. Keeping all moving parts clean and properly lubricated ensures smooth operation and reduces the risk of damage over time.