When it comes to maintaining and repairing a lawn tractor, knowing the layout and function of its individual components is essential. Properly identifying each part helps you troubleshoot issues efficiently and ensures that repairs are made correctly. A clear visual representation can guide you through the process, making it easier to locate and replace specific elements when needed.

Accurate identification of parts not only saves time but also reduces the chances of making mistakes during repairs. With a well-organized reference, even complex machinery can be tackled step by step, ensuring that your tractor runs smoothly for longer periods.

Familiarizing yourself with your machine’s design is a critical first step before diving into any maintenance tasks. By understanding how all the pieces fit together, you can prevent damage and keep everything functioning at its best.

Cub Cadet 2186 Parts Overview

Understanding the key components of a lawn tractor is crucial for effective maintenance and repair. Each element plays a specific role in ensuring the machine operates efficiently. A comprehensive overview allows you to familiarize yourself with the various sections of the equipment, making it easier to identify potential issues and address them promptly.

Essential Components for Operation

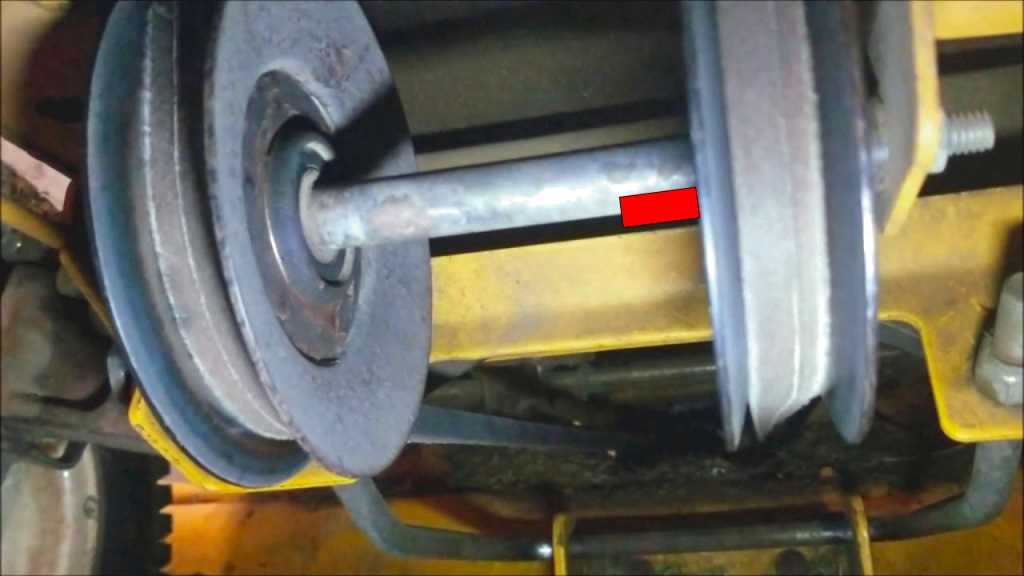

The core elements of any lawn tractor include the engine, transmission, and steering mechanism. These parts work together to provide power and control over the vehicle. Recognizing the function of each component helps you pinpoint areas that might need attention, whether it’s a performance issue or general wear and tear.

Minor Parts and Accessories

In addition to the main parts, there are smaller elements that contribute to the overall functionality of the machine. These can include belts, filters, and wheels. While often overlooked, these accessories play a vital role in maintaining smooth operation and should be replaced when necessary to avoid performance degradation.

How to Identify Key Components

Recognizing essential parts within your machine is a critical step in maintenance and repair. By understanding the layout and function of each component, you can quickly troubleshoot issues and ensure that all elements are in working order. Knowing where each piece fits into the overall structure makes the repair process much more manageable.

Start with the Engine and Power System

The engine is the heart of your equipment, providing the power needed to drive the machine. It’s important to know its key components, such as the carburetor, spark plug, and air filter. Regularly checking these elements ensures optimal performance and prevents issues from escalating into more complex problems.

Check the Transmission and Steering Mechanism

In addition to the engine, the transmission and steering system are vital for smooth operation. Identifying key parts like belts, gears, and linkages can help you address any control or movement issues. Proper maintenance of these components is essential to maintain the machine’s efficiency and maneuverability.

Tips for Efficient Parts Replacement

Replacing damaged or worn-out components can significantly extend the life of your equipment. Knowing how to efficiently identify, source, and replace elements ensures the machine runs smoothly and reliably. Follow these tips to streamline the replacement process and avoid unnecessary delays.

Preparation and Organization

Before beginning the replacement process, ensure you have everything you need. Proper planning helps avoid disruptions and keeps the work area organized.

- Gather necessary tools: Make sure you have the right tools for the job, such as wrenches, screwdrivers, and any specialty tools needed for your machine.

- Check replacement components: Confirm that you have the correct replacement parts that match the specifications of your equipment.

- Clear work area: Keep the workspace clean and clutter-free for better accessibility and safety.

Step-by-Step Replacement Process

Following a methodical approach during the replacement ensures that no steps are missed and that everything is installed correctly.

- Turn off and disconnect: Always ensure the machine is powered off and disconnected from any power source before starting the work.

- Remove the damaged components: Carefully remove the worn-out parts, keeping track of any fasteners or accessories that might be reused.

- Install the new parts: Follow the manufacturer’s instructions to install the new components, making sure everything is securely fastened.

- Test the machine: After installation, run a test to ensure everything functions correctly and make any necessary adjustments.