Maintaining your outdoor machinery is essential for ensuring long-lasting performance and efficiency. Whether you’re tackling small or large tasks, understanding how each component functions can make a significant difference in the overall care of your equipment.

In this section, we will explore the key elements of a popular model’s cutting mechanism. We will break down the system’s functionality and offer useful tips for ensuring smooth operation. With proper attention to detail, you can optimize its efficiency and extend its lifespan.

By learning how different components interact, you can easily identify any wear and tear, enabling you to make timely replacements or repairs. This proactive approach will help you avoid costly fixes and keep your equipment running at its best for years to come.

Understanding the John Deere X500 Mower Deck

Properly functioning cutting equipment plays a crucial role in maintaining a well-kept lawn. Understanding the internal mechanisms of this system can help you ensure that everything works together seamlessly. From the rotating blades to the various supporting components, each part contributes to the overall efficiency of the machine.

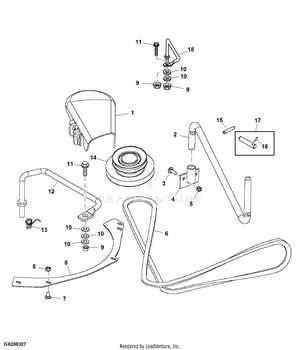

The system consists of a combination of mechanical elements that allow for smooth movement and effective cutting. Key components such as the drive system, pulley assembly, and blade mounts all work in unison to provide consistent performance. Keeping track of these elements’ condition is essential for preventing issues that could impact operation.

When performing maintenance, it’s important to regularly check for wear and tear on each part. Regular inspections allow for early identification of potential problems, which can be addressed before they cause significant damage. This proactive approach helps extend the life of the equipment while maintaining optimal performance.

Key Components of the 54 Inch Deck

The cutting mechanism of a lawn care machine relies on several interconnected parts that work together to ensure efficient operation. These components, ranging from the blades to the drive system, each play an integral role in achieving the desired results. Understanding how each part functions can help ensure that the equipment runs smoothly and effectively.

One of the most important elements is the rotating blades, which are responsible for cutting the grass with precision. Alongside them, the pulley system and drive belts ensure that the blades rotate at the right speed for optimal performance. These components must be properly maintained to prevent issues such as uneven cuts or excessive wear.

Additionally, the blade mounts and spindles help secure the blades in place, allowing for stable and consistent operation. Regularly checking these parts for wear or damage can help prevent breakdowns during operation. Ensuring that all components are functioning as they should is key to keeping the machine in top condition.

How to Maintain Your Mower Deck

Regular maintenance is essential to keep your equipment running smoothly and efficiently. By focusing on key areas such as cleaning, lubrication, and component checks, you can prevent costly repairs and extend the lifespan of the system. A well-maintained machine performs better and ensures reliable results every time.

Cleaning and Inspection

One of the most important maintenance tasks is keeping the cutting system free from debris. Grass clippings, dirt, and other residues can accumulate over time, affecting performance. After each use, clean the system thoroughly, paying special attention to the blades and surrounding areas. Regularly inspect for any signs of wear or damage, especially on components that undergo significant stress, like the spindles and drive belts.

Lubrication and Adjustments

Proper lubrication is vital for reducing friction between moving parts. Apply the recommended lubricants to key areas such as the pulleys and spindles to ensure smooth rotation and prevent wear. Additionally, periodically check the tension on belts and adjust them as necessary to avoid slippage and ensure optimal performance during operation.