Every machine is made up of various elements that work together to ensure its smooth operation. Understanding how each component functions and interacts with the others is essential for maintaining efficiency and longevity. Whether you’re troubleshooting an issue or performing routine upkeep, familiarizing yourself with these internal elements can save time and prevent unnecessary repairs.

By examining the intricate layout and function of each individual piece, you gain valuable insights into the mechanics of the entire system. This knowledge is key for both experienced users and newcomers who wish to take better care of their equipment.

With the right approach, maintenance becomes more straightforward. Regular checks and part replacements, when necessary, can extend the lifespan of your machine. A clear understanding of how everything fits together will make this process more efficient and help avoid costly mistakes.

Understanding the Stihl FS38 Components

Each piece of equipment is built with several crucial elements that contribute to its overall functionality. These components, though small, play a significant role in ensuring the machine operates smoothly and efficiently. Gaining a solid understanding of how these individual pieces work together helps in troubleshooting and regular maintenance tasks.

By recognizing the specific function of each component, users can better address issues that arise and maintain the equipment with confidence. The key to keeping everything running optimally lies in knowing when a particular part may need attention, whether it’s due to wear and tear or normal usage.

Regular inspection of the different elements, including the engine, transmission, and other supporting parts, is essential for preventing breakdowns. Understanding the role of each element allows you to focus your efforts on the most critical areas during maintenance, ensuring better performance and fewer disruptions in the long run.

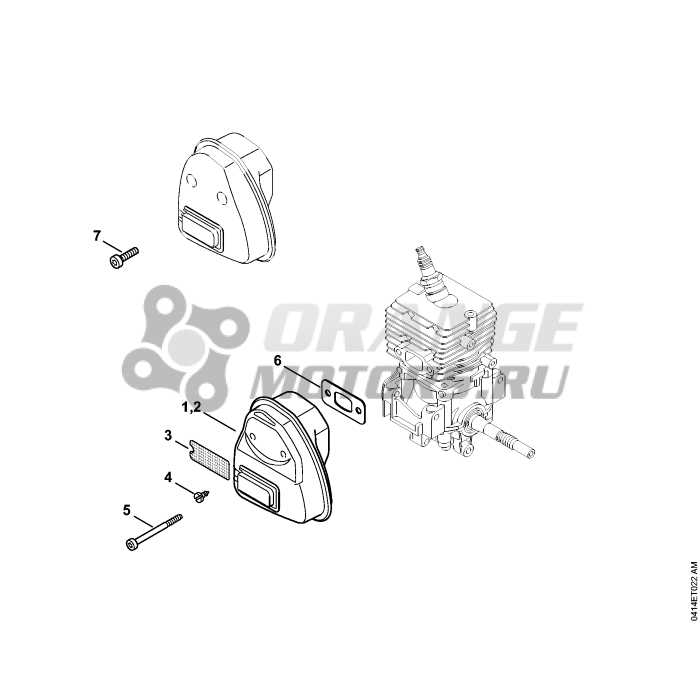

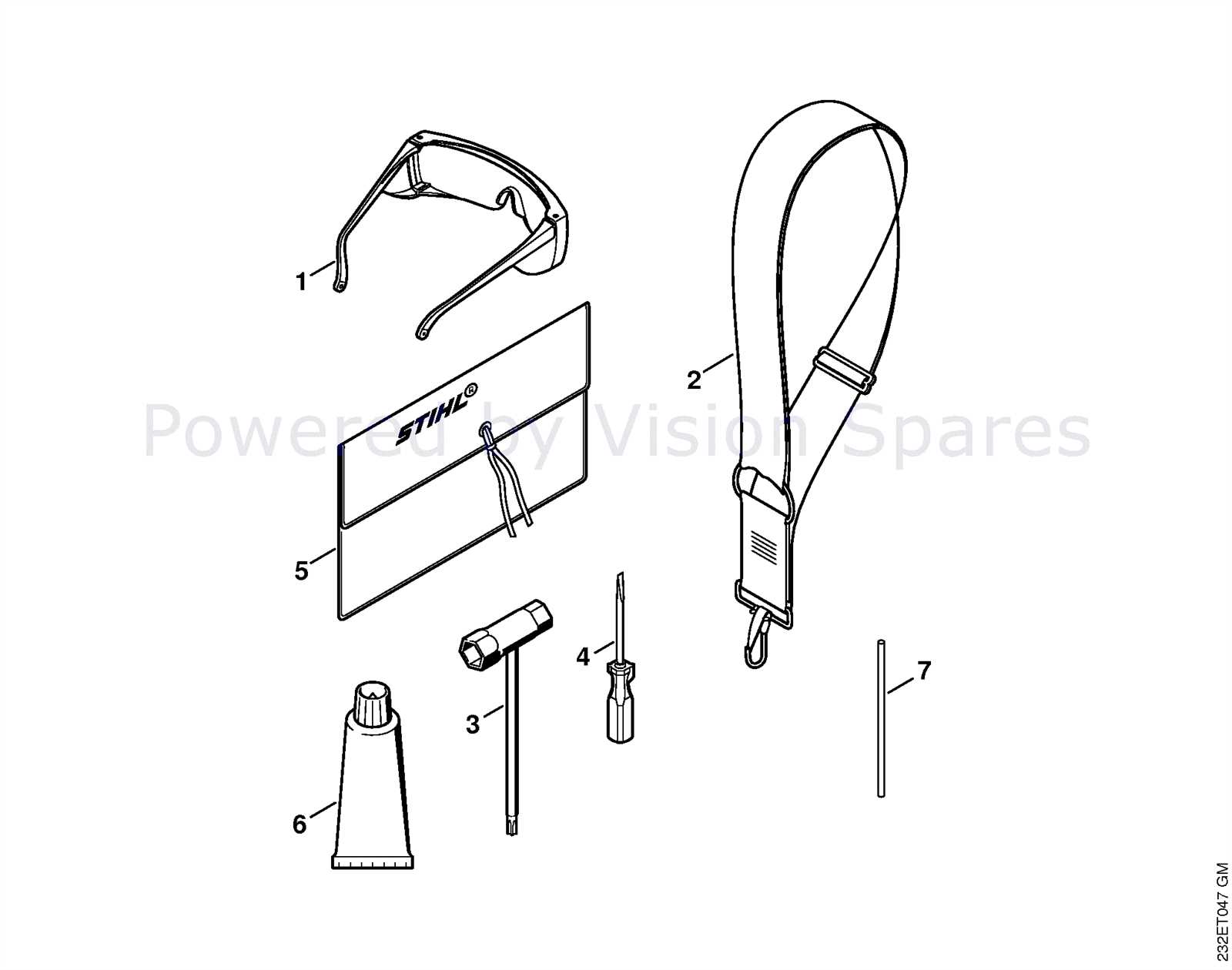

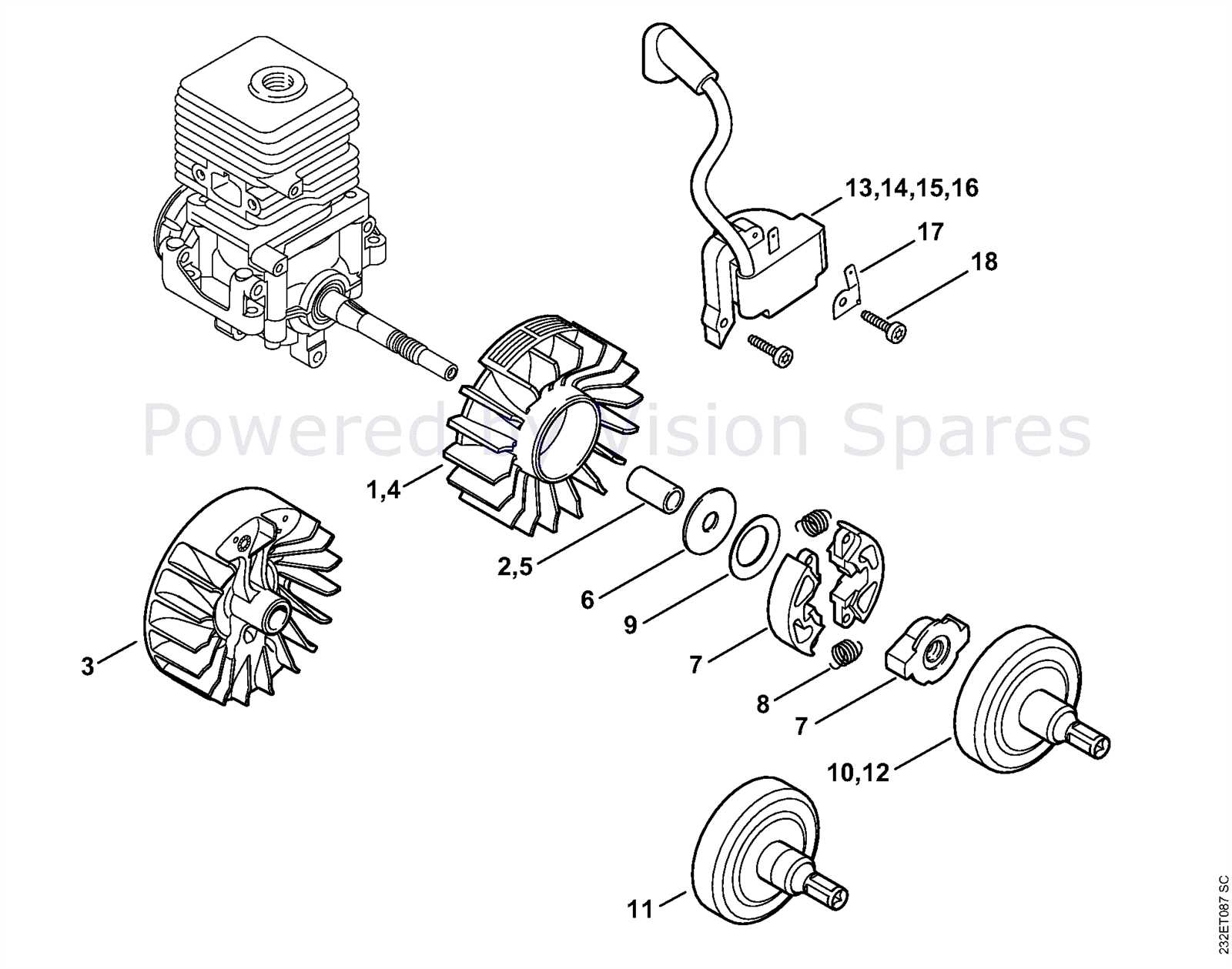

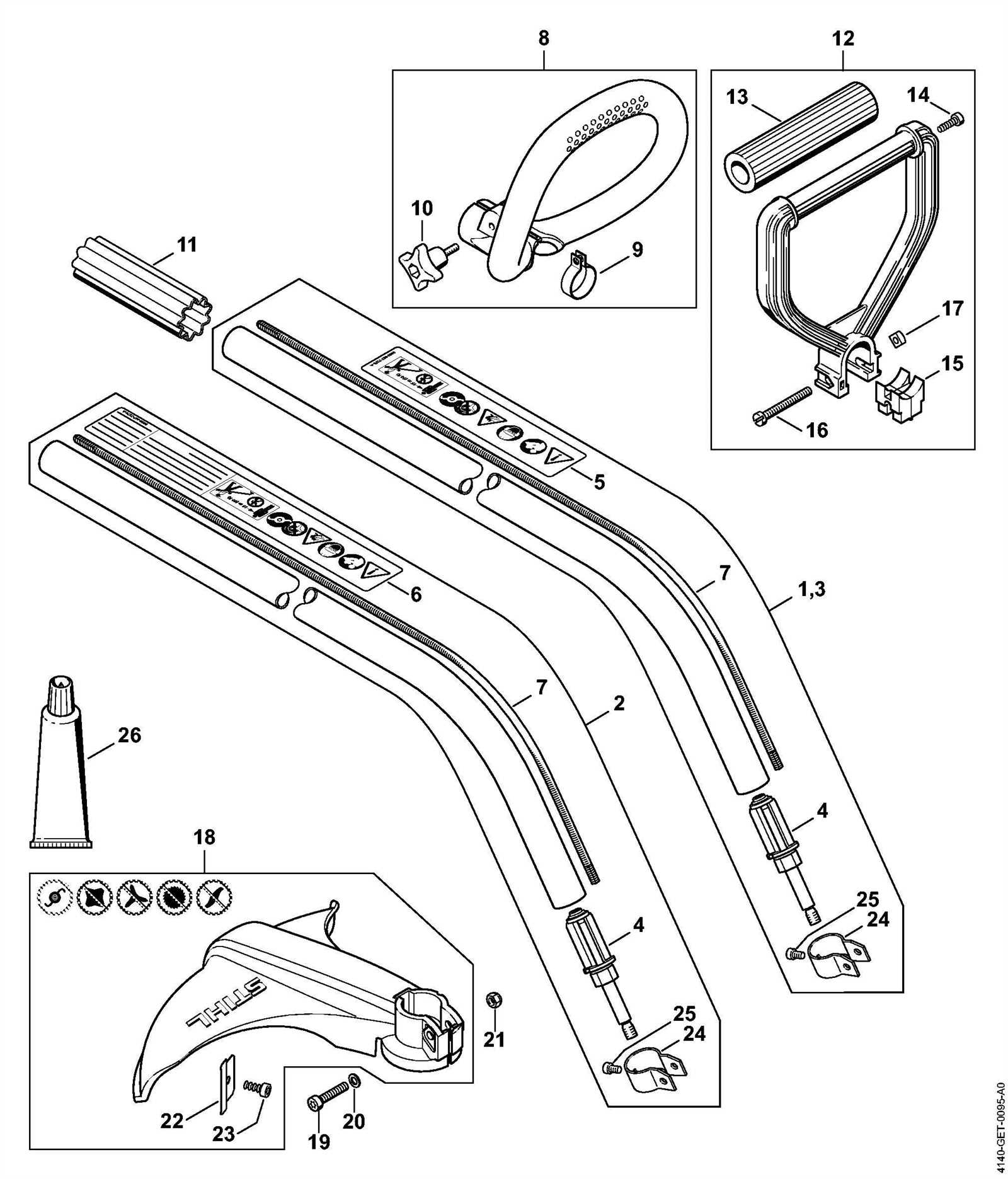

Identifying Key Parts in the Diagram

Understanding the layout of a machine involves recognizing the essential elements that make up its structure. Each part has a unique role in ensuring the device operates as intended, and knowing how to identify these components is crucial for effective maintenance. By familiarizing yourself with the locations and functions of these key pieces, you can more easily troubleshoot or replace them when needed.

Key components are often highlighted in visual guides to show how they connect and interact within the system. Recognizing the function of each item allows for better diagnosis and quicker repairs. This knowledge also helps in routine checks, ensuring that no critical element is overlooked during maintenance.

Focusing on the most important sections, such as the engine and control mechanisms, ensures you address the core functionality of the device. Once you are able to identify and understand the role of these elements, you’ll be better prepared for any necessary adjustments or part replacements to keep your equipment running smoothly.

How to Maintain Stihl FS38 Parts

Proper maintenance of your equipment ensures longevity and peak performance. Keeping individual components in top shape reduces the risk of malfunctions and costly repairs. Regular upkeep involves cleaning, checking for wear, and replacing any damaged elements. By maintaining the critical parts of your machine, you help prevent breakdowns and ensure smooth operation over time.

Routine Checks and Cleaning

Regular cleaning and inspection of key components are vital to extend the life of your equipment. Dirt and debris can accumulate in various parts, affecting their function. Gently cleaning the elements with appropriate tools, such as brushes or compressed air, removes any build-up that could hinder performance. Periodically inspecting for signs of damage or wear will also help you catch issues early.

Part Replacements and Adjustments

Over time, some components may require replacement due to wear. Keeping spare parts on hand allows for quick replacements, minimizing downtime. Ensure you replace any worn-out elements with compatible parts to maintain the system’s efficiency. Additionally, making minor adjustments to tension and alignment helps maintain optimal performance, ensuring the equipment works as it should.