Maintaining outdoor machinery is essential for its longevity and performance. Understanding the various elements of your equipment can help with repairs, troubleshooting, and ensuring optimal function. Whether you’re an experienced user or new to lawn care, having a clear understanding of the individual pieces and how they interact can save both time and money.

Efficient operation relies heavily on knowing which parts work together and where issues might arise. Accessing a detailed breakdown of these components provides a clearer path for identifying malfunctions or areas that require attention. A thorough guide is invaluable in ensuring each element is correctly installed and maintained.

Proper knowledge of the machinery’s construction enables smoother repairs, quicker fixes, and an overall better user experience. This article will explore how to use such resources effectively, giving you the tools to keep your equipment running efficiently for years to come.

Understanding Lawn Equipment Components

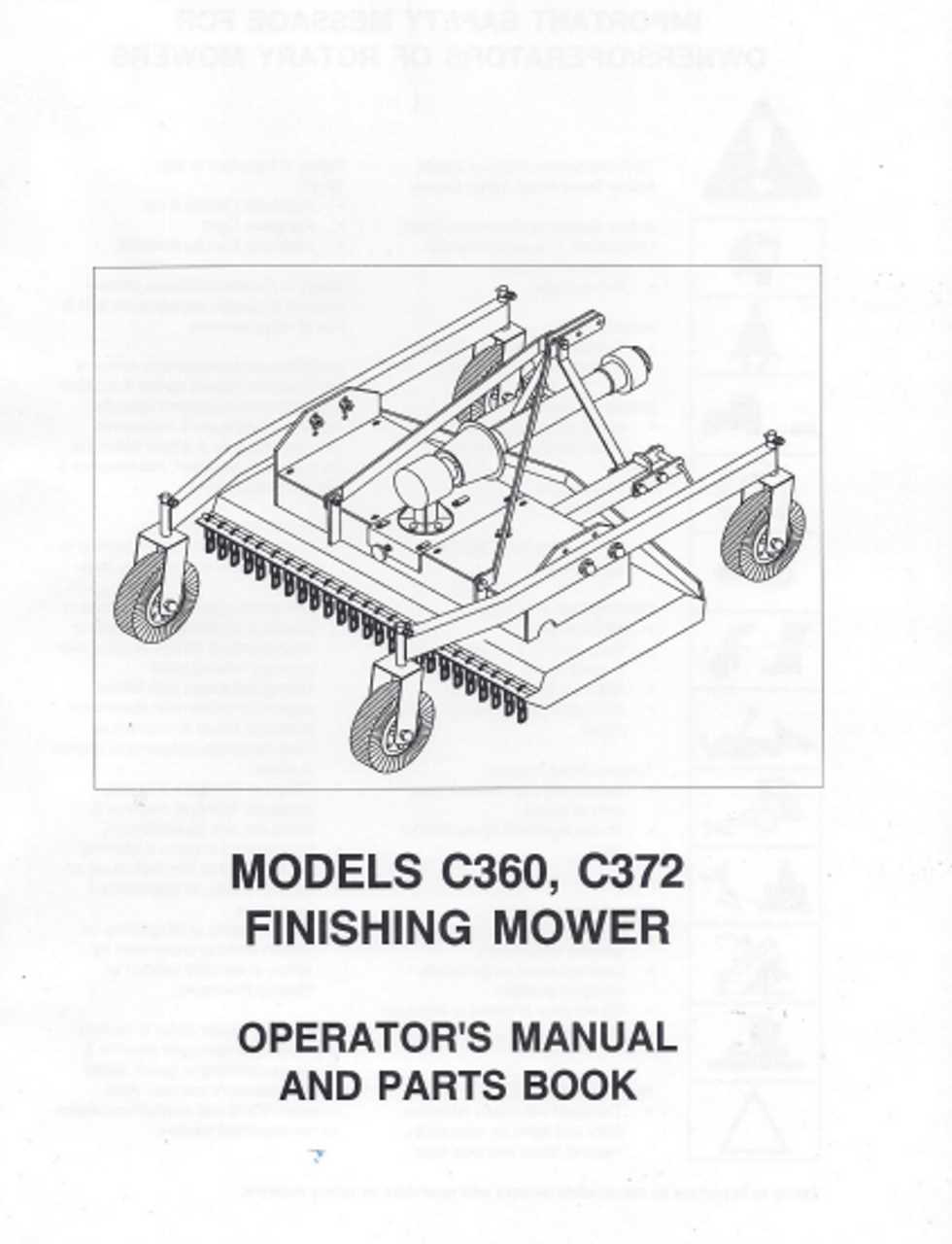

To operate and maintain outdoor machinery effectively, it’s crucial to familiarize yourself with the individual elements that make up the system. Each component serves a specific function, and understanding their roles can help prevent issues and improve the overall performance of your equipment. Whether you’re repairing a malfunction or performing routine maintenance, knowing the layout and interaction of the key pieces is essential for a smooth operation.

Main Functional Elements

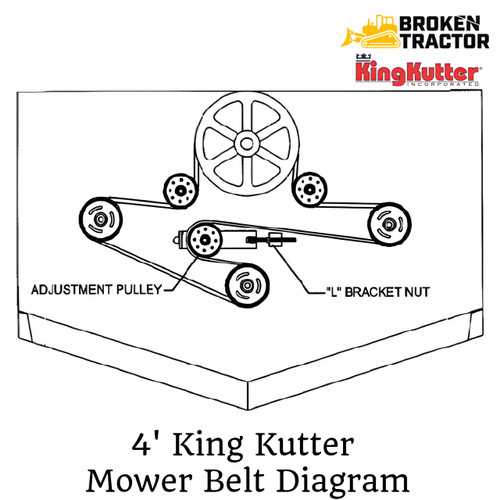

The primary components of any lawn tool can be categorized based on their function in the system. From the drive system that propels the machine to the cutting mechanism that ensures clean results, each part works in harmony to deliver the desired outcome. The blades, belts, pulleys, and housing are integral to efficient performance and need to be checked regularly to ensure they are functioning properly.

Maintenance and Troubleshooting

Understanding the layout of these elements also aids in troubleshooting and maintenance. If one part of the machine starts malfunctioning, recognizing the symptoms and knowing where to look first can save you time and money. Regularly inspecting components such as the transmission system, lubrication points, and cutting equipment will keep the system running smoothly and extend its lifespan.

How to Use the Parts Diagram Effectively

When it comes to maintaining or repairing machinery, visual references can greatly simplify the process. A well-detailed guide that breaks down the components and their connections helps users understand how each part fits into the whole system. By following these illustrations closely, users can quickly locate problematic areas and determine the necessary steps for a repair or upgrade.

Identifying Components is the first step in making good use of these guides. Begin by matching the labeled sections with the physical counterparts on the equipment. This visual mapping allows you to easily recognize any missing, damaged, or worn-out components. Understanding where each element is situated within the system is key to successful maintenance.

Following Assembly Instructions is another crucial aspect. Often, a visual guide will include detailed steps for putting parts together or disassembling them for servicing. By referring to these instructions, you ensure proper alignment and avoid errors that could affect the performance or safety of the machine. This approach can also help prevent the risk of incorrectly assembling or reinstalling components.

Common Issues and Maintenance Tips

Like any mechanical equipment, outdoor machinery can experience wear and tear over time. Regular use can lead to certain issues that impact performance or cause breakdowns. Understanding common problems and having effective maintenance strategies in place can prevent unnecessary repairs and extend the lifespan of your tool. Knowing what to check and how to address minor concerns can save you both time and money.

Common Mechanical Problems

One of the most frequent issues involves the drive system, which may experience wear on belts or pulleys. These parts can become loose or frayed, affecting the tool’s efficiency. Another common problem is the cutting system, where blades may become dull or misaligned. Regular inspection of these elements helps identify issues before they escalate into more serious damage. Additionally, clogged filters or inadequate lubrication can cause overheating or hinder performance, so it’s crucial to stay on top of these maintenance tasks.

Routine Maintenance and Prevention

Proper upkeep involves regular cleaning and checking of key components. Start by ensuring all fasteners are tightened, as loose bolts can cause vibrations that may damage the system. Change the oil and air filters as recommended in the manual, and keep the cutting mechanism sharp for better efficiency. Checking the belts and pulleys for signs of wear and replacing them promptly prevents costly repairs later. Maintaining a consistent cleaning schedule and inspecting for wear helps keep your equipment running smoothly.