Modern seating solutions come with advanced features that enhance comfort and convenience. Understanding how these systems work is essential for anyone looking to repair, maintain, or simply get the most out of their furniture. Whether you’re troubleshooting an issue or planning a DIY fix, knowledge of the internal components is key to successful outcomes.

Each component plays a specific role in the overall function of the seating system. From motors to levers, and from springs to upholstery, every piece contributes to the smooth operation and comfort. Recognizing how these elements work together can help identify problems quickly and efficiently.

Familiarizing yourself with these mechanisms will also empower you to make informed decisions when selecting replacement parts or seeking professional assistance. By gaining a deeper understanding of the structure, you can better appreciate the design and functionality behind these modern innovations in comfort.

Understanding Power Recliner Components

Modern furniture designed for enhanced comfort contains a variety of specialized mechanisms that enable smooth movement and flexibility. These internal systems are built to offer support and adjustability, making them an essential part of the overall user experience. Familiarizing yourself with these components can make a big difference when it comes to repairs and maintenance.

The key components that drive these systems typically include motors, cables, and springs, all of which work in harmony to adjust the seating position. Motors are responsible for generating the necessary force, while cables and springs ensure that the movement remains fluid and responsive. Additionally, sensors and switches play a crucial role in controlling the various settings.

Understanding how each part contributes to the overall functionality is vital for both troubleshooting and regular upkeep. For example, a malfunctioning motor or a disconnected cable may prevent the seat from adjusting properly. Recognizing these components’ roles will help you pinpoint potential issues faster and reduce downtime.

How to Read a Power Recliner Parts Diagram

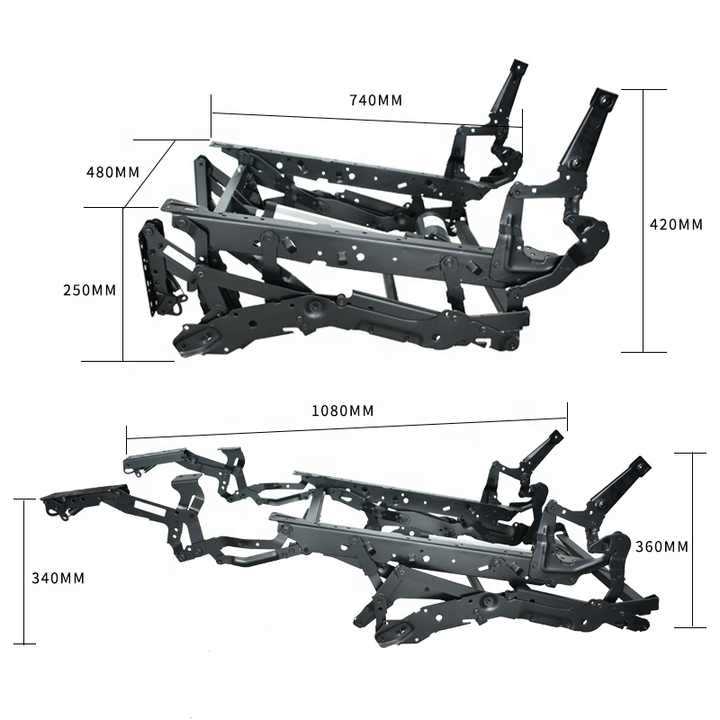

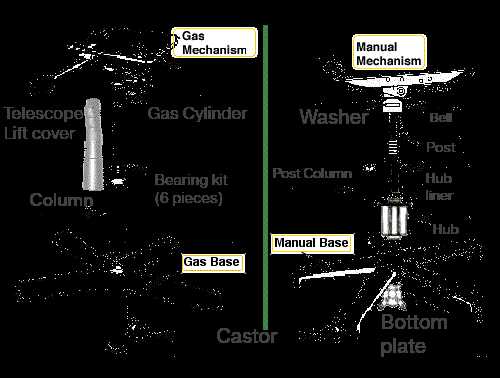

When dealing with the internal mechanisms of advanced seating systems, understanding the layout of components is crucial for effective troubleshooting and repairs. A visual map of the system can provide detailed information on how each element fits together and operates. Knowing how to interpret these visuals ensures you can easily identify parts and address issues accurately.

Identifying Key Components

The first step is to familiarize yourself with the symbols and labels used in the visual guide. Typically, each component is marked clearly, and the diagram may include arrows or lines to show connections between different elements. By recognizing the common symbols for motors, springs, or cables, you can immediately pinpoint the areas you need to focus on during your repairs.

Understanding Component Relationships

Once you know the components, the next step is understanding their relationships. Diagrams often show how parts interact, such as how a motor connects to the moving parts of the seat or how cables and levers work together. This understanding helps when troubleshooting, as you can follow the connections to locate any potential issues.

Troubleshooting Common Power Recliner Issues

When modern seating systems stop functioning properly, identifying the root cause can seem challenging. However, most issues stem from a few common sources that can often be resolved with basic troubleshooting steps. Knowing where to look and what to check first can save time and prevent unnecessary repairs.

One of the most frequent problems is a lack of movement or malfunctioning adjustment features. This is often caused by electrical issues, such as a disconnected or faulty power source. Start by checking the plug and ensuring that all connections are secure. If the system is powered but not responding, the internal wiring or motor could be the issue.

Another common problem involves the seating not holding its position after adjustment. This could be due to a misalignment or worn-out components, such as springs or levers. Inspecting the mechanical parts and making sure everything is in place can help resolve this issue. Additionally, lubricating moving parts can restore smooth functionality.