Every small engine system relies on various intricate components working together to ensure smooth operation. These mechanisms control the fuel flow and air intake, which are essential for efficient combustion. Recognizing how these pieces fit together can significantly improve your ability to maintain and troubleshoot issues that may arise.

Identifying each element within the assembly helps you understand its role in the larger system, making repairs and adjustments easier. Knowledge of the specific function of each component ensures better handling when the engine shows signs of malfunction, such as rough idling or starting difficulties.

Proper care and attention to these elements can extend the life of your engine, keeping it in optimal condition. Through understanding the structure and function of each piece, users can address minor issues before they evolve into major problems, saving both time and money in the long run.

Understanding Engine Fuel System Components

Every small engine depends on a well-organized fuel delivery system to ensure optimal performance. The success of this system lies in the seamless interaction between different components that regulate fuel and air intake for efficient combustion. Recognizing how each element functions individually and in conjunction with others is crucial for maintaining smooth operation and troubleshooting problems when they arise.

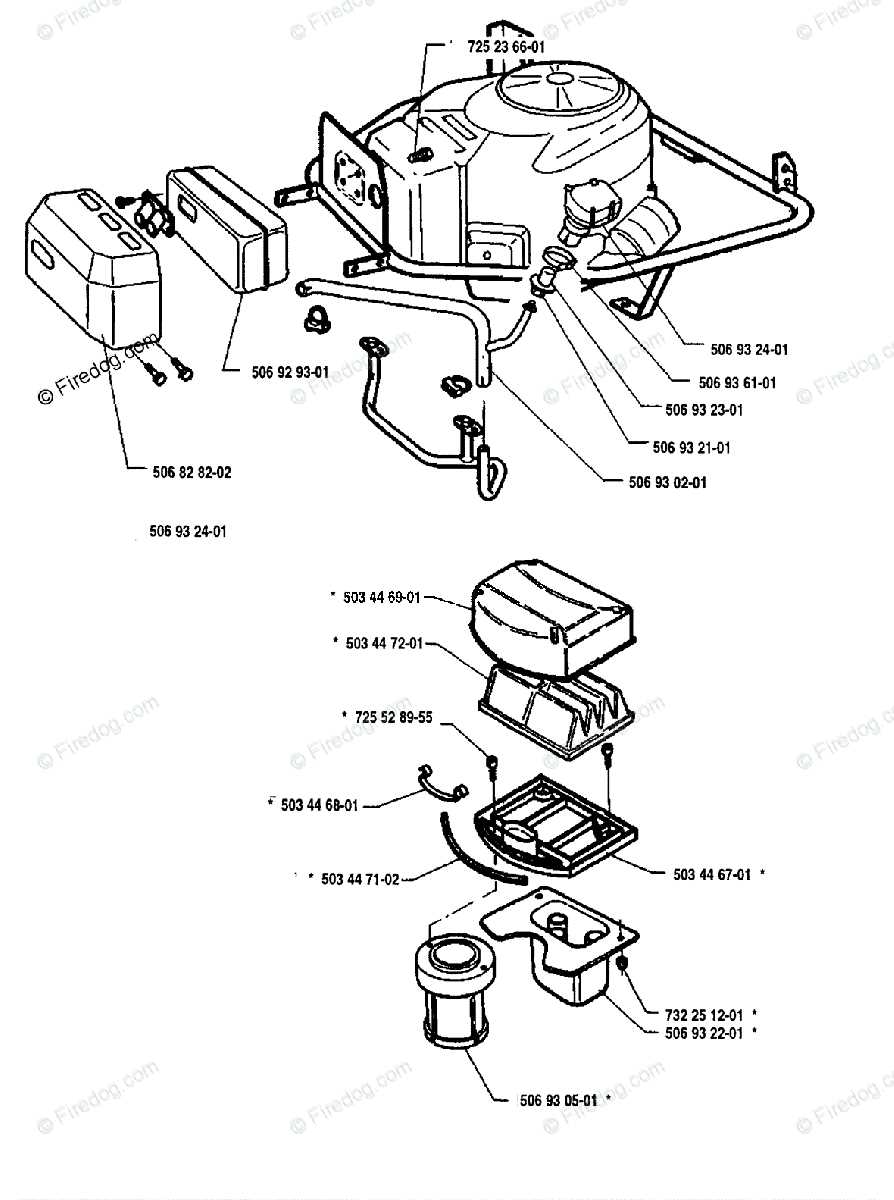

Key Elements in the Fuel Delivery System

The system consists of several key components that each play a distinct role. The fuel chamber holds the fuel, while the air intake valve manages the air flow that mixes with fuel to create the right mixture for combustion. Additionally, the throttle valve controls the speed of the engine by adjusting the amount of air and fuel entering the chamber. Understanding these components allows for easier identification of issues like poor starting or irregular engine performance.

Impact of Proper Maintenance

Regular inspection and cleaning of the fuel system can prevent many common issues that lead to engine malfunction. Keeping each component free of dirt and debris ensures that the fuel mixture remains optimal, which is essential for maintaining power and efficiency. Proper care also extends the lifespan of the system, reducing the likelihood of costly repairs.

How to Identify Key Engine Fuel System Components

Recognizing the critical components of the fuel system is essential for efficient engine management and troubleshooting. Each element plays a role in regulating the flow of fuel and air to ensure proper combustion. By learning how to identify these components, you can easily pinpoint areas of concern when the engine is not performing optimally.

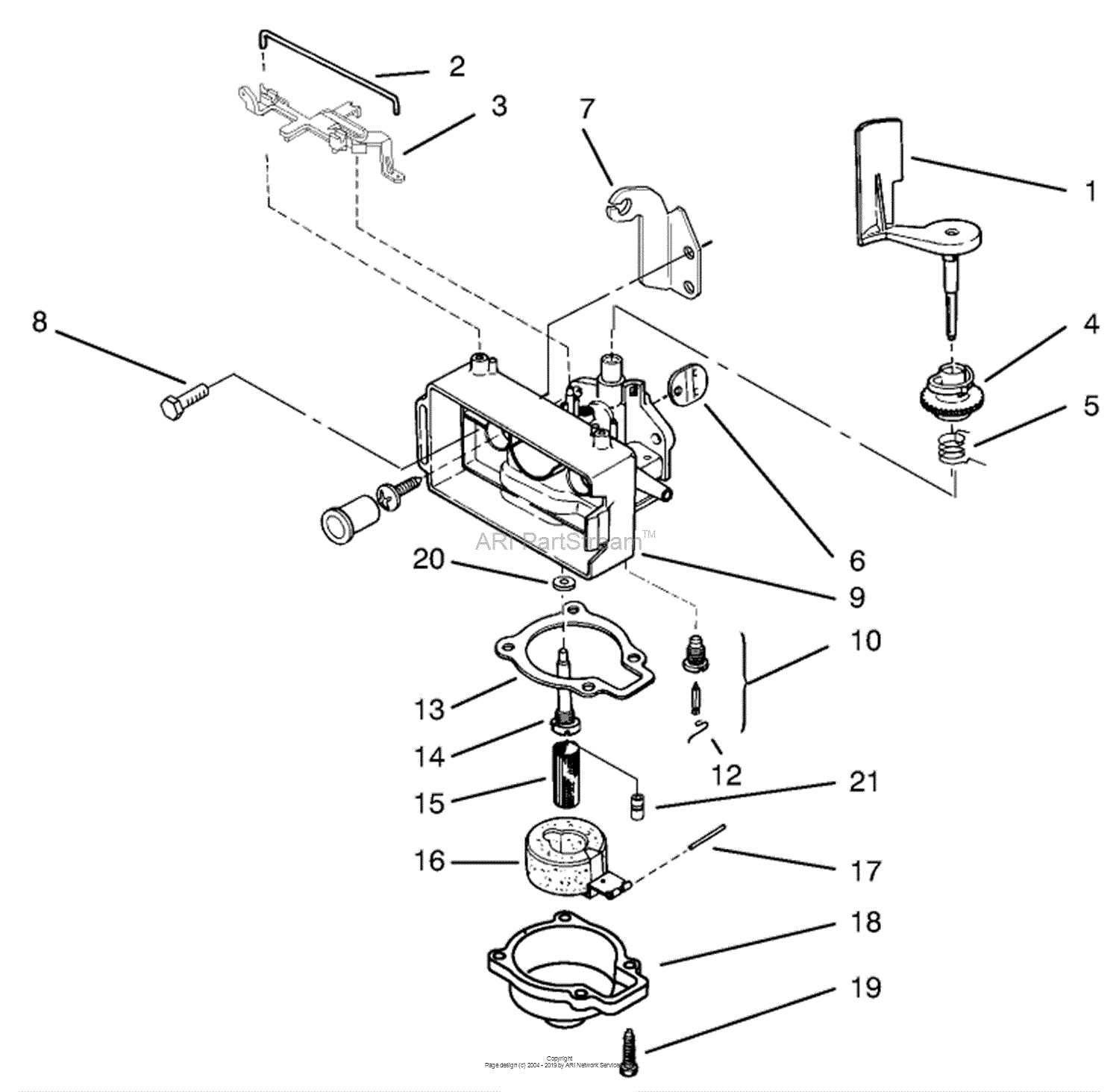

Identifying the Main Components

The fuel bowl holds the fuel, providing a steady supply to the system. The needle valve regulates the fuel flow, ensuring that only the required amount enters the chamber. Another vital element is the air filter, which prevents debris from entering the system and disrupting the air-fuel mixture. Each of these parts is essential for smooth engine operation, and recognizing them is the first step toward effective maintenance.

Common Signs of Malfunction

Knowing how each part functions allows you to detect signs of malfunction early. If the engine stalls or struggles to start, it may be due to a blocked needle valve or a clogged air filter. Regular inspection and cleaning of these components can prevent such issues and ensure that the engine operates efficiently over time.

Common Issues with Engine Fuel Systems

Engine fuel systems are prone to several common issues that can affect performance. Understanding these problems and their causes is key to maintaining smooth operation. Often, poor performance can be traced back to issues with fuel delivery, air intake, or improper fuel mixtures. Identifying these problems early can help avoid costly repairs and ensure the system operates efficiently.

Fuel Flow Obstructions

One of the most common issues is a clogged fuel line or filter. When debris or old fuel accumulates, it can obstruct the flow of fuel, causing the engine to stall or fail to start. Regular cleaning of these components can help maintain a steady fuel flow and prevent interruptions in engine performance.

Air-Fuel Mixture Problems

Improper air-fuel ratios can lead to inefficient combustion, causing the engine to run roughly or sputter. This can occur if the intake valve is blocked or if the fuel system is not adjusted correctly. Regular inspection and fine-tuning of the system can prevent these issues and keep the engine running smoothly.