Proper maintenance of farming machinery is crucial for its longevity and efficiency. Understanding the various components and their functions allows for easier troubleshooting and repairs. Having access to a detailed visual representation of each part ensures that you can make informed decisions when working on your equipment.

By examining the key elements that make up your machinery, you can identify common issues and address them before they lead to significant breakdowns. With the right tools and knowledge, maintenance tasks become simpler and more manageable, helping you keep your farm operations running smoothly.

Familiarizing yourself with the internal structure of your equipment can also assist in optimizing performance and reducing downtime. Whether you’re dealing with wear and tear or aiming for preventative upkeep, knowing what each part does will help you take the right approach.

Understanding Agricultural Equipment Components

Every farming machine consists of various essential elements that work together to perform specific tasks. Each component has its role, contributing to the overall efficiency and functionality of the equipment. Recognizing these parts and their interactions ensures smoother operations and simplifies maintenance.

Machines designed for cutting, gathering, or conditioning materials rely on a combination of mechanical systems, including cutting mechanisms, conveyors, and drive systems. Understanding how each part contributes to the overall process allows for more effective troubleshooting and repair.

Familiarity with the individual parts also makes it easier to identify wear and tear early, reducing the risk of larger mechanical failures. By knowing which elements are most likely to require attention, you can plan for maintenance and keep downtime to a minimum.

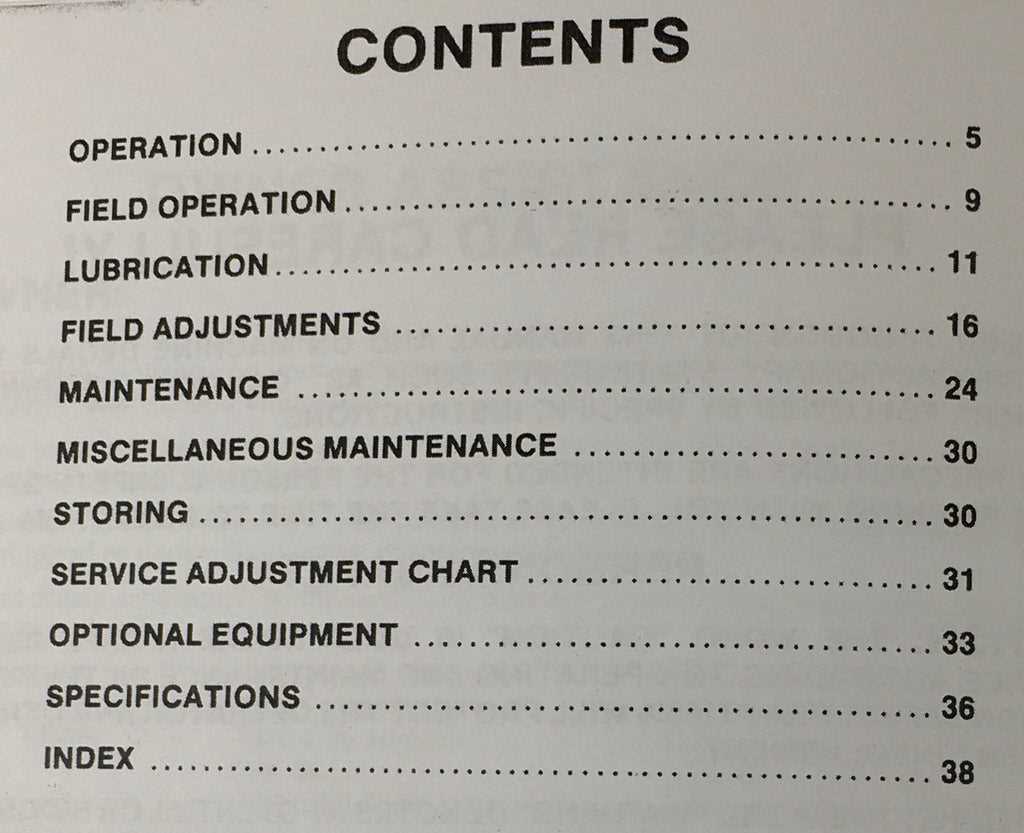

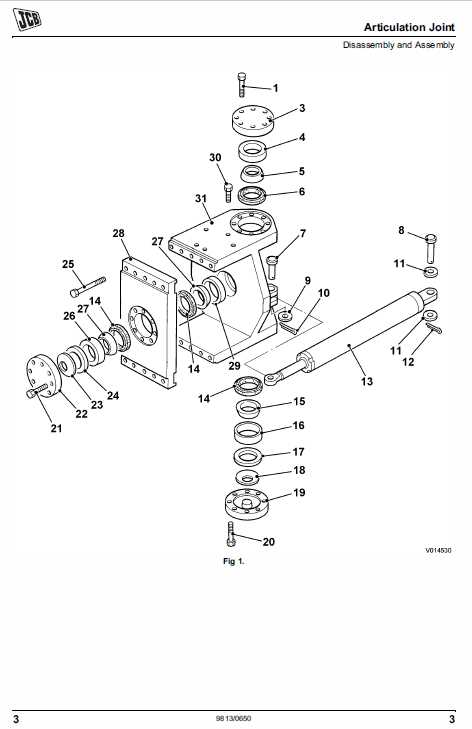

How to Read the Parts Diagram

Understanding the visual representation of a machine’s components is essential for effective maintenance and repairs. A well-detailed image allows you to easily locate specific elements, identify their functions, and recognize their relationships with other parts. Being able to interpret this kind of illustration can save time and help prevent mistakes during the maintenance process.

Interpreting Symbols and Labels

Most illustrations feature symbols and labels that correspond to specific components. These symbols are standardized and designed to provide clear identification for each part. By familiarizing yourself with these symbols, you can quickly determine the part names and their positions in the machine’s layout.

Identifying Connections and Relationships

In addition to the parts themselves, the diagram shows how these components connect and interact with one another. Arrows and lines typically indicate the flow of power or movement between elements. Understanding these connections helps you visualize how the machine operates as a whole and makes it easier to troubleshoot issues when they arise.

Common Repairs for Agricultural Equipment

Maintaining farm machinery involves addressing a variety of common issues that arise during operation. Whether due to wear and tear or environmental factors, certain parts are more likely to need attention over time. Recognizing the most frequent problems and knowing how to address them can help reduce downtime and extend the machine’s lifespan.

Among the most common repairs are issues with cutting blades, belts, and drive mechanisms. These components experience frequent stress and can wear out or become misaligned. Regular inspection and timely replacement are key to ensuring optimal performance and avoiding more costly repairs later on.

Another frequent repair involves the conveyor and conditioning systems. These parts often experience damage from debris or excessive use, leading to decreased efficiency. Proper cleaning and lubrication, as well as replacing damaged or worn-out components, help keep these systems functioning smoothly.