Proper maintenance and efficient operation of agricultural machinery rely on a clear understanding of its structure and individual components. Knowing the arrangement and function of each part is essential for troubleshooting, repair, and optimizing performance.

In this section, we will explore the key elements that make up these heavy-duty tools. From the cutting mechanism to the supporting framework, understanding each segment ensures a smoother operation and longer lifespan of the equipment.

By familiarizing yourself with these parts, you can improve your ability to recognize wear and tear, replace damaged sections, and perform necessary upkeep. This knowledge empowers operators to make informed decisions, reducing downtime and enhancing overall efficiency.

Understanding Machine Components

To ensure a smooth operation and maximize the efficiency of agricultural equipment, it’s essential to have a clear understanding of the individual components that make up the machinery. Each element plays a critical role in the overall functioning, and recognizing how they interact can help maintain optimal performance. Knowing the layout and features of these parts helps operators identify potential issues early and take corrective measures before they lead to more significant problems.

Key Elements of the Equipment

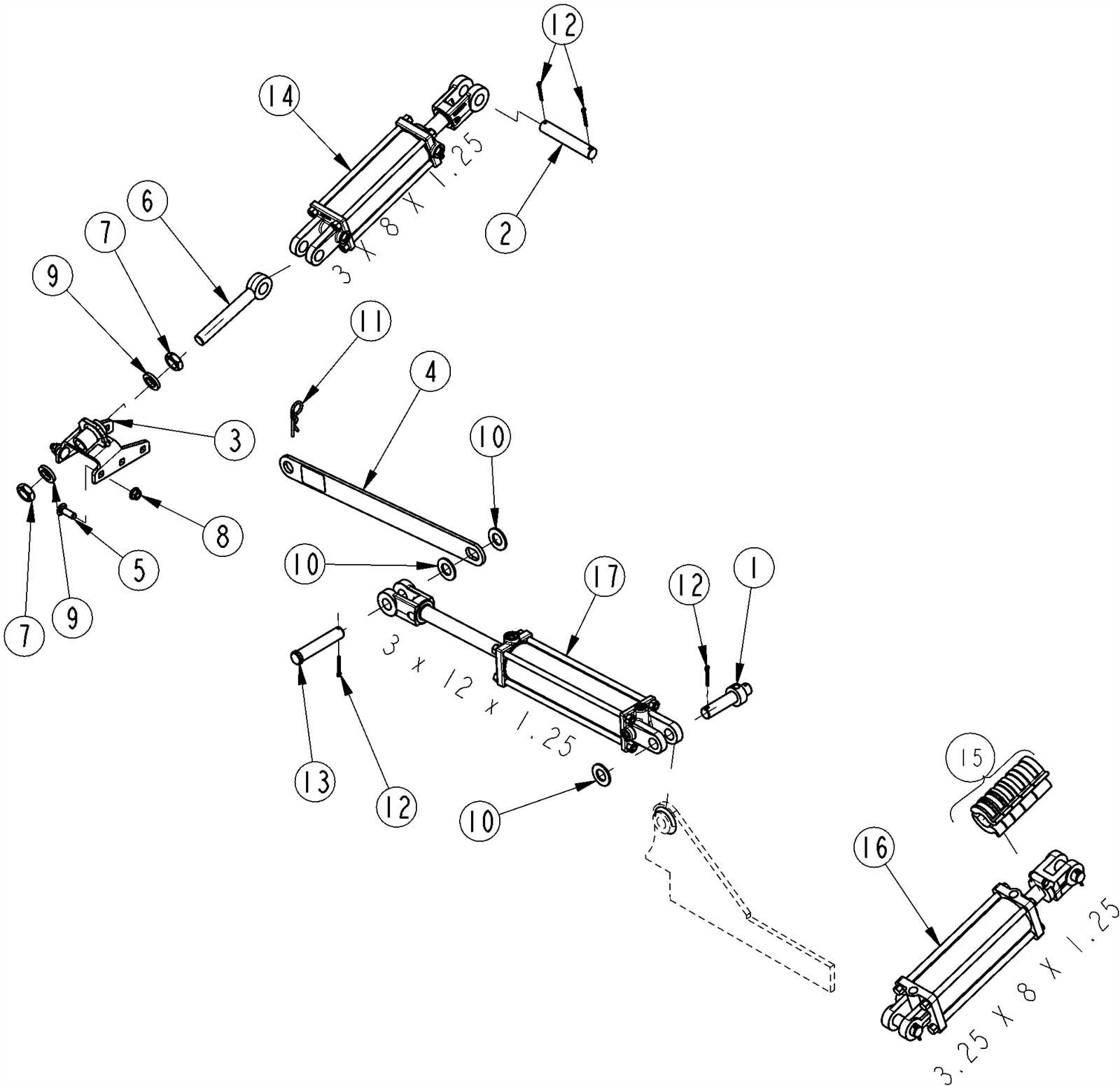

The core of any heavy-duty machine includes several integral pieces, such as the frame, drive system, and cutting mechanism. These components work in unison to achieve the desired results, whether it’s trimming vegetation or clearing land. The frame supports and houses the rest of the elements, while the drive system ensures the proper motion and power transmission, making the equipment functional.

Maintenance and Troubleshooting

Understanding the structure of the machine also aids in identifying wear and tear, ensuring that critical parts are checked regularly for potential damage. Proper care and attention to each component can extend the equipment’s lifespan and reduce the need for costly repairs. Regularly inspecting each section for any issues such as misalignment or loose connections will ensure that the machine remains in top working condition.

Identifying Key Parts and Functions

Every agricultural tool consists of several crucial elements, each serving a specific function to ensure efficient operation. Recognizing these components and understanding their roles helps users perform maintenance tasks with precision and tackle issues promptly. Whether it’s for cutting or power transmission, each section has a purpose that directly impacts the machine’s performance.

Drive System: This mechanism is responsible for transferring power from the engine to the working components. It ensures that the machinery operates smoothly and that power is distributed effectively for optimal performance.

Blades and Cutting Mechanism: The cutting unit is one of the most critical aspects of the equipment. It includes the blades, which are designed to handle tough vegetation. Understanding their positioning and maintenance requirements is key to preserving the efficiency of the equipment.

Frame and Support: The frame serves as the backbone of the machinery, providing structural integrity and supporting the other components. It must be checked regularly for wear and tear, as any damage could compromise the machine’s stability and safety during operation.

How to Maintain Your Equipment

Regular maintenance is essential to ensure that your agricultural machinery operates at peak performance. By keeping track of specific care tasks, you can extend the lifespan of your tool, improve its efficiency, and prevent costly repairs. A well-maintained machine not only performs better but also reduces the risk of unexpected breakdowns during crucial operations.

Regular Inspections

One of the first steps in maintenance is conducting routine inspections of the machine. Check for any loose components, signs of wear, or buildup of debris that could interfere with performance. Pay close attention to moving parts such as the drive system and cutting units, ensuring they are properly aligned and free from obstruction. Regular inspections allow you to identify potential issues before they escalate into major problems.

Cleaning and Lubrication

Keeping the machinery clean is vital for smooth operation. After every use, clear away dirt, grass, and other debris that may accumulate around the moving components. Additionally, lubrication is crucial to minimize friction and prevent premature wear. Regularly apply the appropriate lubricants to the moving parts to maintain optimal functionality and reduce the chances of rust or corrosion.