When it comes to maintaining and repairing outdoor equipment, knowing how the individual components function is essential. Understanding the layout of the various elements can significantly ease the troubleshooting process, whether you are performing routine maintenance or addressing a malfunction. This knowledge ensures better performance and helps extend the lifespan of the equipment.

Exploring the different sections of your equipment, from the engine to the transmission, reveals how each part contributes to its overall operation. Every piece plays a critical role in ensuring smooth functionality, and understanding their interaction can prevent common issues that arise during use.

Accurate identification and maintenance of these parts can lead to more efficient repairs, saving both time and money. This guide offers a closer look at the key elements that make up the system, providing valuable insights for anyone looking to enhance their repair skills or improve the performance of their equipment.

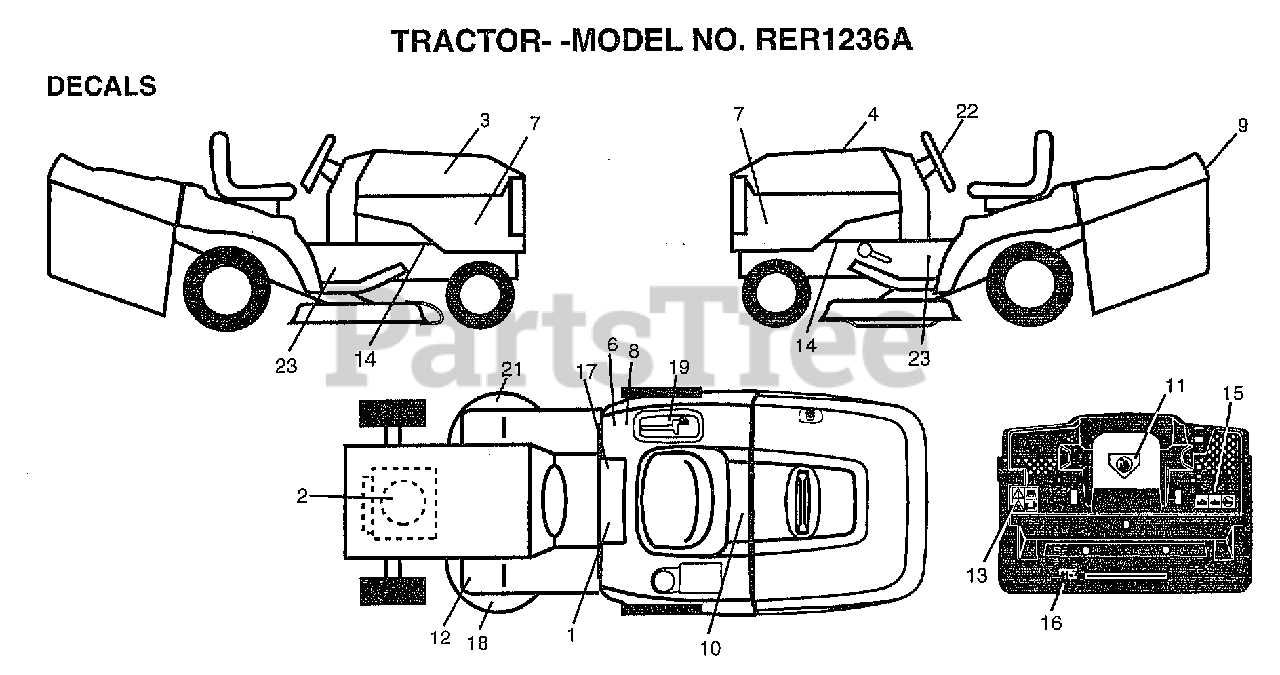

Rally Lawn Mower Parts Breakdown

Understanding the internal structure of outdoor equipment is key to effective operation and troubleshooting. Each element within the system serves a specific function, contributing to the overall performance. Breaking down these components helps to identify potential issues more efficiently and ensures that maintenance tasks are executed correctly.

Core Components and Their Functions

The engine, transmission, and drive system form the heart of the equipment. The engine powers the machine, while the transmission ensures smooth power delivery to the wheels or cutting mechanism. Additionally, components like the fuel system, spark plugs, and filters work in tandem to maintain optimal performance. Each part must be properly aligned and functioning to prevent operational disruptions.

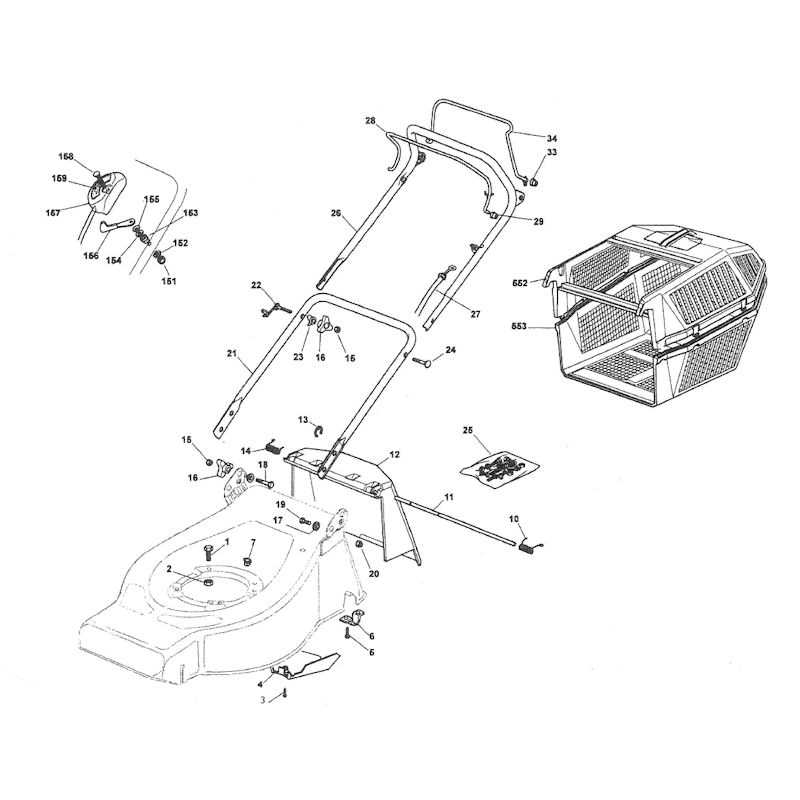

Maintaining and Replacing Key Elements

Regular upkeep of these critical components ensures that your equipment operates at peak efficiency. Replacing worn-out or damaged pieces, such as belts, pulleys, or blades, is essential to maintaining the system’s performance. Paying attention to the wear and tear of each part can prevent costly repairs in the future and extend the life of the equipment.

Understanding Key Components and Functions

Effective performance of outdoor equipment relies on the seamless interaction of various critical elements. Each component plays a vital role in ensuring that the machine operates efficiently and without interruption. Understanding the function of these parts allows for better care, smoother repairs, and quicker identification of issues when they arise.

The Power Source

The engine is the core power source of the system, responsible for converting fuel into mechanical energy. This energy is transmitted to other parts, driving the overall motion and enabling the device to perform its tasks. Regular inspection of the engine is necessary to ensure fuel efficiency and reliable startup, as even small issues can significantly affect performance.

Transmission and Drive Mechanism

The transmission system is responsible for transferring power from the engine to the working parts. It regulates speed and ensures that motion is transferred appropriately, whether for cutting or moving the equipment. Components like belts and pulleys are integral in this process, and maintaining them in optimal condition prevents breakdowns and ensures smooth operation.

Repair and Maintenance Tips for Longevity

To ensure the long-term durability of outdoor equipment, regular maintenance and timely repairs are essential. Taking a proactive approach to care helps avoid major breakdowns and enhances overall performance. By staying on top of maintenance tasks, users can extend the life of their machines and reduce the need for costly repairs.

Routine Inspections and Cleaning

One of the simplest ways to maintain equipment is through regular inspections. Checking for any visible damage, wear, or loose connections can prevent minor issues from escalating into serious problems. Cleaning key components, such as the air filter, engine parts, and belts, also plays a crucial role in maintaining efficiency. Keeping these areas free of debris and dirt helps avoid unnecessary strain on the system.

Replacing Worn-Out Components

As parts age, their effectiveness diminishes, which can lead to decreased performance. Regularly replacing worn-out elements, such as belts, blades, and spark plugs, is vital for maintaining optimal function. Identifying signs of wear early on can prevent unexpected breakdowns and ensure smooth operation for extended periods.