Proper maintenance of lawn care tools requires a clear understanding of their individual components. Whether you’re a seasoned gardener or a beginner, knowing how each piece functions can help ensure your equipment runs smoothly. A breakdown of the elements involved allows for easier repairs and better performance overall.

Identifying each component and its role is essential when attempting any repairs or upgrades. Recognizing the connections between parts will not only save time but also prevent costly mistakes during the process. When you have a solid grasp of how each part contributes to the operation, it becomes easier to troubleshoot issues effectively.

In this guide, we will explore how to identify key elements, provide tips on simple repairs, and discuss methods to improve the longevity of your equipment. By understanding the components, you’ll be able to maintain a well-functioning tool, ensuring optimal performance year-round.

Understanding Lawn Equipment Components

Each piece of outdoor equipment is made up of various elements that work together to provide efficiency and reliability. A clear understanding of these components is crucial for effective use, maintenance, and troubleshooting. When you are familiar with the key elements of your tool, it becomes easier to perform repairs and make adjustments when necessary.

Key Elements and Their Functions

The heart of any lawn tool lies in the different functional parts. The engine, wheels, and handles are some of the essential components that ensure the equipment moves and performs tasks efficiently. Each component has a specific function, whether it’s generating power, providing control, or delivering results on the grass. A thorough understanding of how these pieces fit together helps you maintain and repair them when needed.

Common Signs of Wear and Tear

Over time, even well-maintained equipment can show signs of wear. Recognizing these signs early on can prevent further damage and costly repairs. For example, worn-out belts, rusted blades, or loose bolts can all affect performance. Knowing the warning signs helps you identify problems quickly, allowing for timely fixes and extending the tool’s lifespan.

Common Parts and Their Functions

Every piece of outdoor equipment is built with essential elements that serve specific functions, ensuring optimal performance. Understanding these key components is critical to maintaining and operating the tool effectively. By recognizing the role each element plays, users can easily identify issues and make necessary adjustments or repairs.

Engine and Power Source

The engine is the powerhouse of the equipment, converting fuel or electricity into mechanical energy. It provides the necessary force to operate other components such as the blades and wheels. A well-maintained engine ensures smooth operation and can greatly extend the lifespan of the entire tool. Regular checks on the engine’s oil levels and cleanliness can prevent breakdowns.

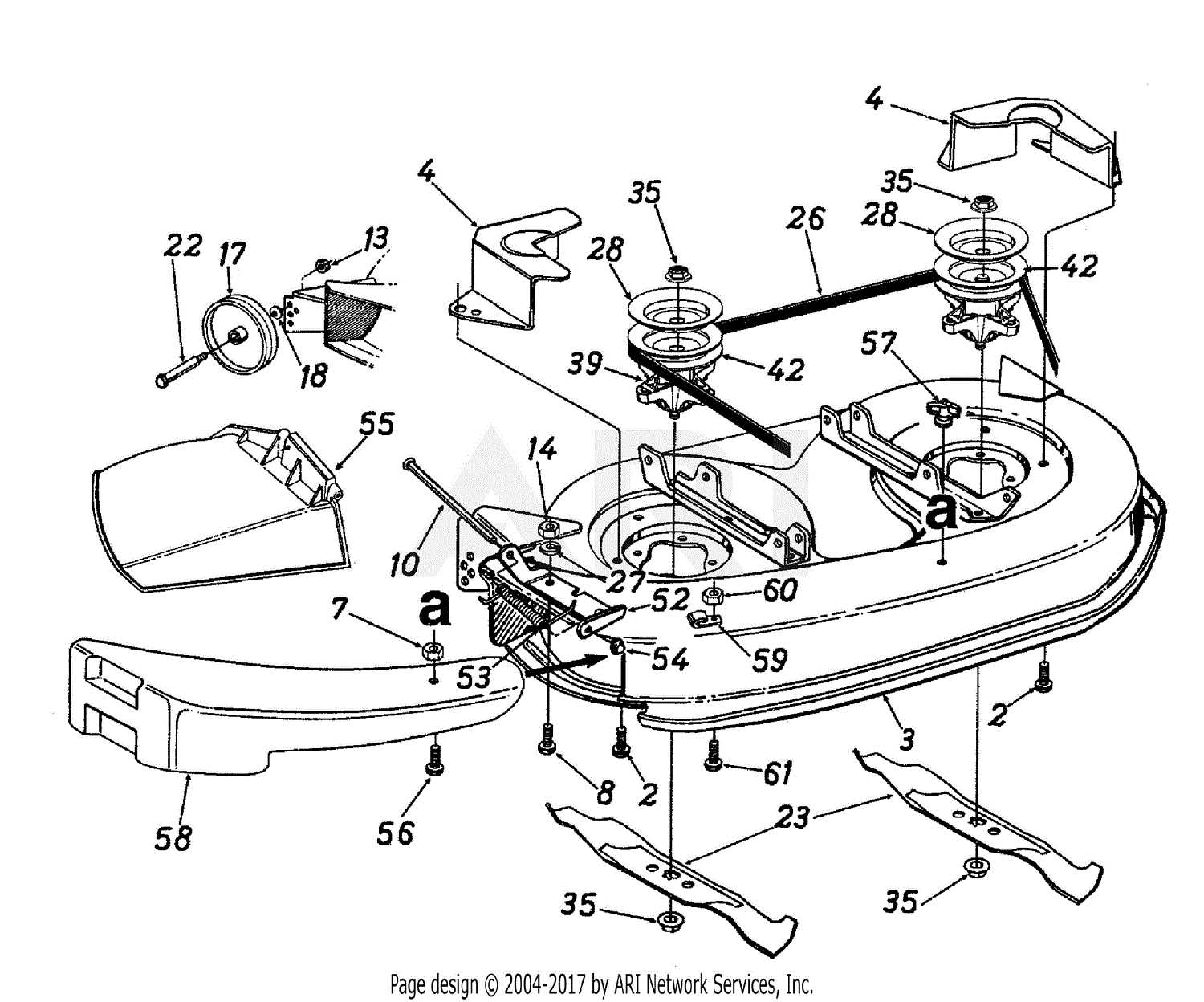

Cutting Mechanism and Blades

The cutting mechanism, often comprising sharp blades, is responsible for trimming the grass. Blades need to be in good condition to ensure precise cutting and a clean lawn. Over time, blades may become dull or damaged, leading to uneven cuts. Sharpening or replacing the blades when necessary helps maintain the tool’s effectiveness.

How to Identify Lawn Equipment Components

Recognizing the different elements of outdoor tools is essential for both regular maintenance and troubleshooting. Identifying each part ensures that you can address any issues that arise and properly replace or repair damaged components. Knowing what each piece does allows you to quickly find solutions to any mechanical problems.

Check the User Manual

The easiest way to start identifying components is by referring to the user manual. Most manuals include detailed diagrams and descriptions of each element, including their functions and locations. This resource can guide you through the process of familiarizing yourself with the equipment’s structure and understanding how the parts interact.

Examine the Tool’s Structure

Take a close look at the tool’s overall build. Larger components like the engine, handles, and wheels are easy to identify, while smaller parts such as bolts and belts may require a more detailed inspection. Pay attention to the connections between different elements, as this can often reveal the part’s function. For instance, parts connected directly to the engine will likely have a role in powering or controlling the tool.

Tips for Accurate Component Recognition

Identifying the correct elements of your outdoor tool can be a challenging task, especially when you’re not familiar with its design. However, with the right approach, you can easily recognize each component and understand its purpose. Proper recognition of these elements is crucial for troubleshooting and performing necessary repairs.

Use Visual Clues and Markings

One of the most straightforward methods of recognizing components is by examining the visible markings and labels. Many tools include part numbers, brand logos, or specific symbols that can help you identify different sections. Here’s what you should look for:

- Look for numbers or letters stamped or printed on components.

- Pay attention to color-coding, which can indicate specific functions or areas.

- Examine shape and size – different parts have unique shapes that can easily be distinguished once you know what you’re looking for.

Consult the Manual and Online Resources

If you’re unsure about a particular element, consult the user manual. Most manuals provide an overview of all components with labeled diagrams. In addition, online resources such as forums, videos, and parts catalogs can offer additional insights. These sources provide visual and textual information that can greatly enhance your recognition skills.

Replacing Components in Lawn Equipment

Replacing worn or damaged elements in your outdoor tools is crucial for maintaining their functionality. Timely replacements not only improve the tool’s performance but also extend its operational life. Knowing when and how to replace specific components ensures that your equipment continues to work efficiently and safely.

Identifying When a Component Needs Replacement

It’s important to recognize the signs that indicate a component is no longer functioning properly. Some common issues include difficulty starting the engine, uneven performance, or visible damage to the parts. When a part shows signs of wear that cannot be fixed by simple maintenance, it’s time for a replacement. Below is a table that outlines common components and their typical replacement intervals:

| Component | Signs of Wear | Recommended Replacement Time |

|---|---|---|

| Blades | Dull edges, cracks, or chips | Every 1-2 years or as needed |

| Belts | Visible cracks, fraying, or slipping | Every 2-3 years |

| Air Filter | Clogged or excessively dirty | Every 1-2 years or more frequently in dusty conditions |

Step-by-Step Replacement Guide

Once you’ve identified the components that need replacement, it’s time to carry out the task. Follow these steps to ensure a proper replacement:

- Turn off the equipment and disconnect any power sources.

- Carefully remove the damaged component, taking note of how it’s connected.

- Place the new component in the correct position, ensuring it fits securely.

- Reassemble any parts that were removed during the process and test the tool to ensure proper functionality.