When working with equipment designed to break down large logs into smaller pieces, it’s crucial to understand the internal mechanisms that make it function. Knowing how each element contributes to the overall process can enhance the efficiency and longevity of the machine.

The key to successful operation lies in recognizing the various components and understanding their roles. Whether you’re troubleshooting or simply performing routine maintenance, a clear understanding of how everything works together will ensure better performance and fewer breakdowns.

Familiarizing yourself with these elements allows you to pinpoint problems quickly and take proactive steps to prevent issues. This knowledge is valuable for anyone looking to keep their equipment running smoothly for years to come.

Understanding Log Splitter Components

To operate a wood-cutting machine effectively, it’s essential to have a clear understanding of how its various components work together. Each part has a specific role that contributes to the overall performance, and knowing how they function in tandem can help you troubleshoot issues and improve efficiency.

The equipment relies on several key mechanisms to process wood efficiently. Recognizing these elements allows you to manage and maintain them better. Whether you’re dealing with the hydraulic system, the cutting blade, or the engine, understanding their roles will help you make informed decisions about repairs or upgrades.

Having this knowledge can also assist in maximizing the machine’s lifespan. Regular checks and maintenance of individual components ensure smoother operations and reduce the chances of unexpected failures. By becoming familiar with the inner workings of your equipment, you are better prepared to handle any challenges that arise.

Key Parts of a Wood-Cutting Machine

Understanding the essential components that power a wood-processing machine is crucial for optimal performance and maintenance. Each key element plays an integral role in ensuring the device operates efficiently, whether you’re using it for commercial purposes or personal tasks.

Hydraulic System

The hydraulic system is responsible for generating the necessary force to cut through wood. It converts fluid pressure into mechanical energy to drive the splitting force.

- Hydraulic Pump: Transforms mechanical power into hydraulic pressure.

- Control Valve: Regulates fluid flow, controlling speed and direction of the splitting force.

- Hydraulic Cylinder: Uses the hydraulic pressure to move the ram, creating force to split wood.

Engine and Power Source

The engine serves as the driving force for the entire machine. It powers the hydraulic system and other moving parts.

- Gas Engine: A commonly used power source for mobile machines.

- Electric Motor: Often used in stationary models for quieter operation.

By knowing these critical components, operators can keep the machine functioning at its best, ensuring long-term reliability and productivity.

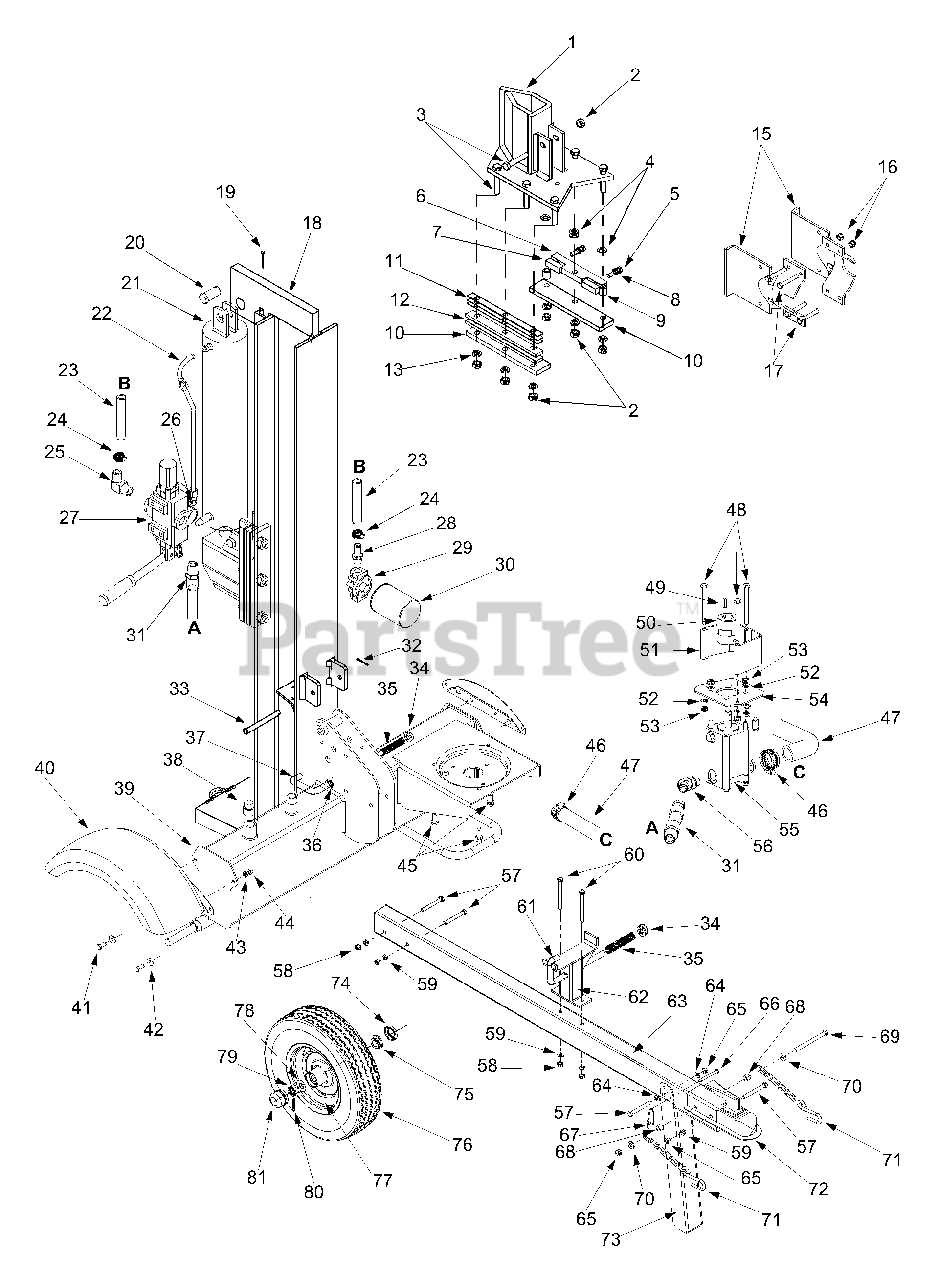

How to Read a Wood Processing Machine Layout

Interpreting the layout of a wood-cutting machine is a valuable skill for understanding its inner workings. By learning how to read a schematic, you can easily identify the components, their connections, and how they function together. This knowledge is especially useful for troubleshooting and performing maintenance efficiently.

First, familiarize yourself with the different symbols used in the layout. These visual representations are designed to simplify the identification of parts and their roles within the machine. Each symbol corresponds to a specific function or component, making it easier to locate and diagnose potential issues.

Next, pay attention to the flow of energy or fluid within the system. Diagrams often include arrows that show how hydraulic fluid or mechanical energy moves through the machine, helping you understand the processes involved in operation. This flow is crucial to identifying areas where a problem might arise, such as blockages or leaks.

By carefully studying these diagrams, you can gain a deeper understanding of how each part interacts and how to keep everything running smoothly.