Understanding the structure and arrangement of mechanical elements is crucial for effective maintenance and repair. This guide offers an in-depth look at how various components are organized, helping users identify, troubleshoot, and replace parts when necessary. With clear explanations and visual aids, navigating complex setups becomes much simpler.

Identifying each piece and understanding its role within the larger system ensures smoother operations. Whether you’re a technician or a DIY enthusiast, knowing how to interpret the layout can save time and reduce errors during repairs.

Accurate part identification is essential not only for assembling or disassembling systems but also for improving the longevity of the equipment. With this knowledge, anyone can approach repairs with confidence, avoiding costly mistakes and enhancing overall performance.

Understanding the 21199 Parts Diagram

To effectively maintain and repair mechanical systems, it’s essential to comprehend the layout and organization of individual components. Knowing where each element fits and how it interacts with others helps ensure proper function and allows for easier troubleshooting when something goes wrong.

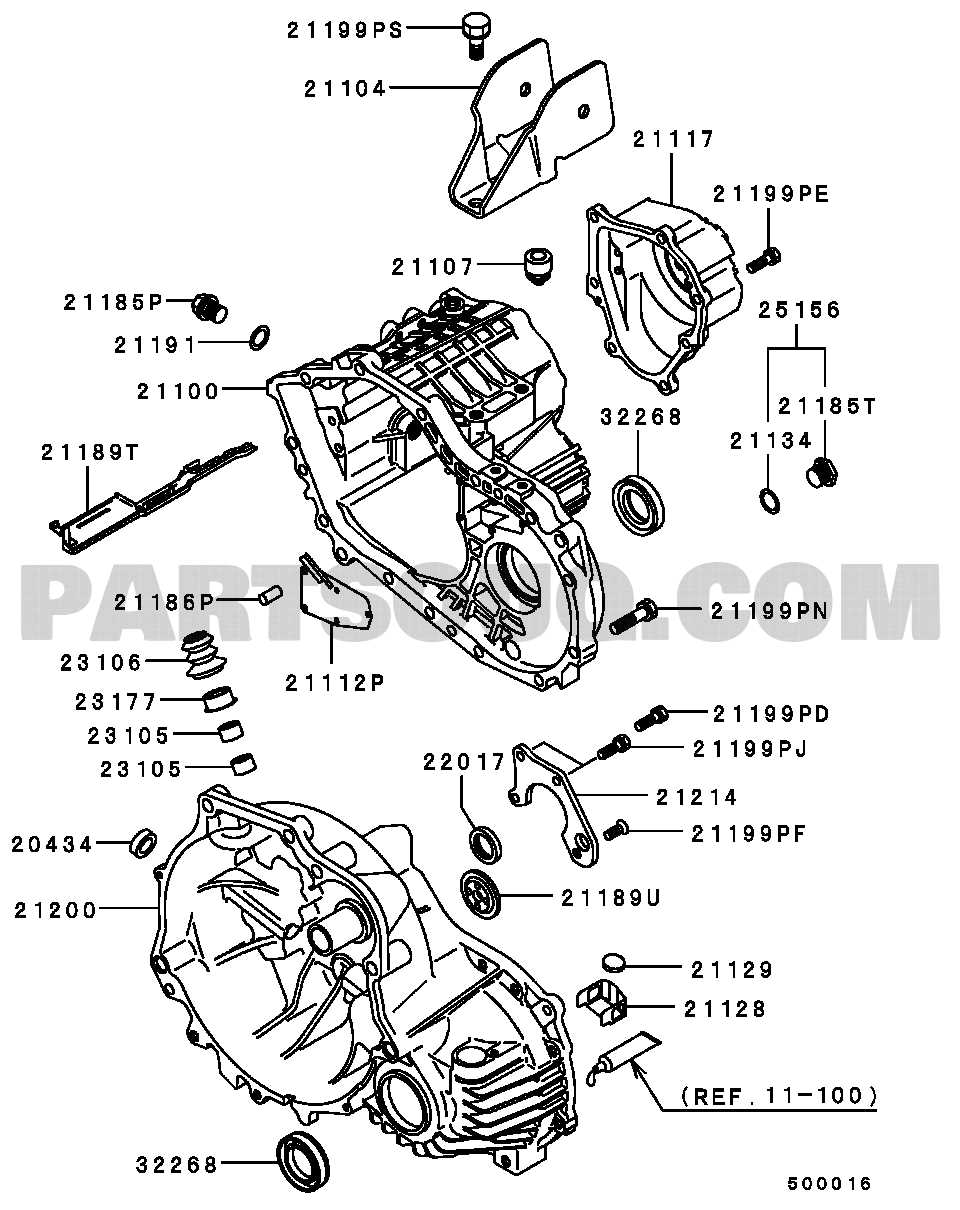

Each system’s structure is typically represented in a detailed chart, which illustrates how the different pieces are connected. By analyzing this visual representation, users can quickly identify each component, its position, and its relationship to other parts, allowing for precise adjustments or replacements when necessary.

Familiarity with this type of visual guide enhances the ability to perform repairs without confusion. Understanding how each part is labeled and where it is located within the overall design helps reduce the risk of mistakes and improves the efficiency of any maintenance tasks.

How to Read the 21199 Parts Layout

Reading a system layout requires understanding how different components are arranged and represented. These visuals typically use clear labeling and organized patterns to help users quickly locate and identify each part within a larger assembly. Mastering this skill allows for precise identification, making it easier to perform repairs and replacements.

To start, focus on the labels next to each part. These are often numbered or named to correspond with specific components in the system. By matching these labels with the corresponding items, users can understand how everything fits together and the function of each element in the overall structure.

Pay attention to the arrangement and lines connecting the components. The lines often indicate how parts interact or connect, while the layout’s structure guides you through the step-by-step process of assembly or disassembly. Familiarity with this visual language helps streamline repairs, ensuring each piece is in its correct position and functioning properly.

Common Issues and Solutions for 21199 Components

When working with mechanical systems, certain problems tend to recur, particularly related to specific elements. These issues can range from improper alignment to wear and tear on crucial parts. Identifying these common challenges early on can save both time and resources, as well as help prevent further damage.

One frequent issue involves incorrect installation or misalignment of components. When elements are not properly placed or connected, it can lead to inefficient performance or malfunction. The solution lies in carefully following the guidelines for assembly, ensuring that each piece is securely in its designated position and aligned as shown in the layout.

Another common problem is wear caused by frequent use or environmental factors. Over time, some components may degrade, affecting the overall functionality of the system. Regular maintenance, including cleaning and replacing worn-out elements, can mitigate these effects and extend the lifespan of the equipment.