When maintaining and repairing mechanical equipment, a clear understanding of its internal structure is essential. Every machine consists of various elements that work together to ensure proper functionality. Identifying and understanding these components is the first step toward efficient troubleshooting and repair.

By exploring the different parts and their roles, you can gain a deeper insight into how the machinery operates. Knowing where each piece fits within the system allows for more accurate and faster repairs. The ability to recognize issues before they escalate can save time and reduce the likelihood of expensive breakdowns.

In this section, we will guide you through the process of identifying key parts and their interconnections. By familiarizing yourself with these details, you’ll be better equipped to handle any challenges that arise, ensuring your equipment runs smoothly for longer periods. Proper maintenance is key to extending the lifespan of your tools, and a solid understanding of the individual components is vital to achieving this goal.

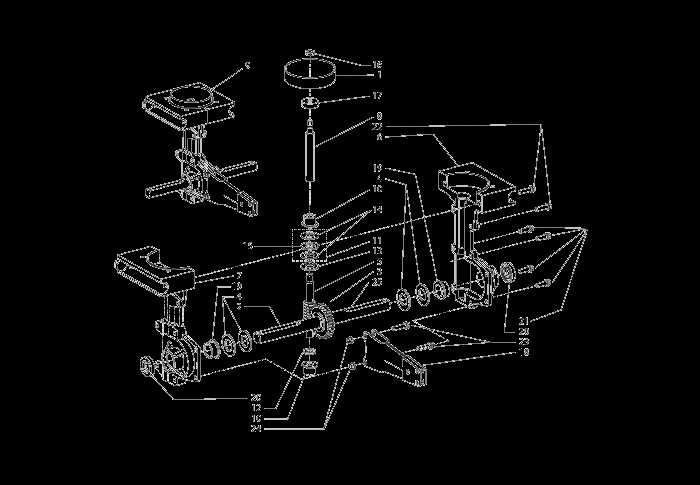

Understanding Machine Component Layout

To successfully maintain and repair any mechanical equipment, it’s crucial to have a clear picture of how the various elements of the machine are organized. A comprehensive layout of the components allows you to see how each part interacts within the system, helping you identify potential problems and guide necessary repairs.

In this section, we will break down the essential components of the equipment and explain their functions. Having a solid understanding of these parts ensures that you can pinpoint issues quickly and proceed with accurate troubleshooting. Below are some key categories that are important to grasp:

- Structural Elements: These are the foundation of the machine, providing support and stability to the entire system.

- Operational Components: Parts responsible for the core functionality, driving the movements and actions within the equipment.

- Control Mechanisms: Elements that regulate and monitor the performance, ensuring the machine runs efficiently.

- Energy Transmission: Parts that facilitate the transfer of energy throughout the machine, allowing for smooth operation.

Once you understand the basic structure and purpose of each component, you’ll be able to recognize the most common issues. This knowledge is a crucial part of proper maintenance and repair, ensuring your equipment remains in optimal working condition for a longer period.

Identifying Key Components in Machine Layout

Recognizing and understanding the critical elements of any equipment is fundamental for efficient troubleshooting and repair. By identifying the most important parts, you gain a clearer view of how the machine operates and where potential problems may arise. This knowledge allows for precise interventions and ensures that the equipment functions optimally over time.

Structural Support Elements

The foundation of the system is composed of various structural components that provide support and stability. These elements are vital for maintaining the integrity of the entire unit and ensure that all parts are securely in place. Some of the key structural components include:

- Frame: The main support structure that holds all other parts together.

- Mounting Points: Locations where individual elements are attached to the frame, allowing for proper alignment.

Functional Operating Elements

These parts are responsible for driving the machine’s actions and carrying out its intended tasks. Understanding how each functional component contributes to the overall operation helps pinpoint issues related to performance. Examples include:

- Motor: The driving force behind the system, providing power to the moving parts.

- Transmission System: The mechanism that transfers power from the motor to other parts, ensuring smooth operation.

By identifying these key components, you can troubleshoot and resolve issues more effectively, ensuring that the equipment continues to work as intended.

How to Use the Component Layout for Repairs

Utilizing a clear layout of the internal elements is crucial when performing repairs. By having a visual representation of the equipment’s structure, you can easily locate the malfunctioning components and understand how they fit together. This knowledge allows you to approach repairs systematically and avoid unnecessary mistakes.

To begin, carefully study the layout to identify the specific parts that need attention. Here are a few steps to guide you through the repair process:

- Examine the Layout: Thoroughly review the entire layout to familiarize yourself with the locations of all critical components.

- Identify Malfunctioning Parts: Pinpoint the parts that may be causing issues by cross-referencing the diagram with the symptoms you observe.

- Check for Compatibility: Ensure that any replacement components match the specifications of the original ones by comparing them with the diagram.

- Disassemble with Caution: Use the layout as a reference when disassembling parts to ensure you don’t miss any steps or cause additional damage.

By following these steps, you can enhance the repair process, making it quicker and more accurate, ultimately helping to restore the equipment to its full functionality.