Maintaining your grooming equipment requires a clear understanding of its internal structure. Every tool consists of several interconnected parts, each playing a specific role in ensuring smooth operation. Familiarizing yourself with these elements not only extends the tool’s lifespan but also improves its efficiency during use.

Understanding the layout of the device helps you troubleshoot issues quickly and accurately. Whether you need to replace a worn-out component or simply clean the inner mechanisms, knowing how everything fits together is crucial for effective maintenance.

This guide will walk you through the key components of your grooming tool, explaining their functions and how to identify potential problems. With this knowledge, you can keep your equipment running like new for a long time.

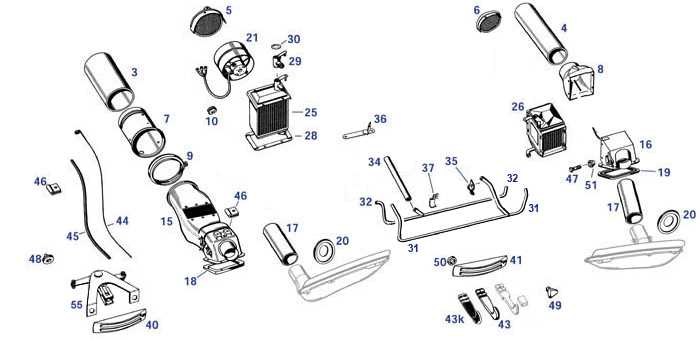

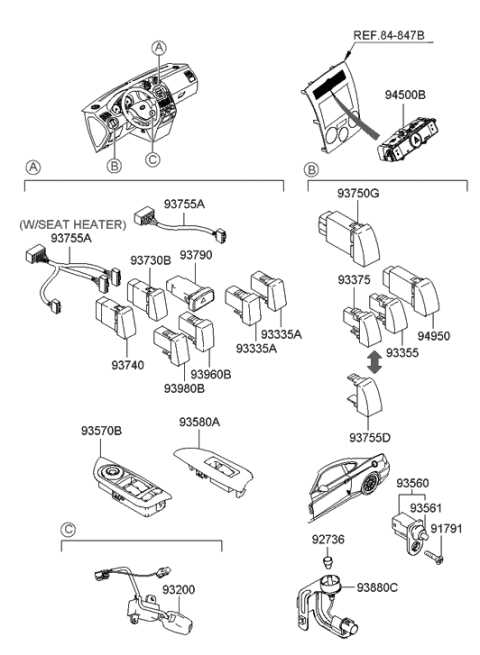

Understanding the Grooming Tool Components

Every professional grooming device consists of various elements that work together to ensure optimal performance. Each component plays a crucial role in the overall functionality of the tool, and understanding how they interact can help you maintain and repair it effectively. The internal structure is designed for precision, so recognizing each part’s role will allow you to troubleshoot issues more efficiently.

Key Components of the Device

The main components include the motor, the cutting mechanism, and the housing that holds everything in place. The motor is responsible for driving the movement, while the cutting mechanism includes blades or similar parts that perform the actual trimming. The housing ensures everything stays secure and protected during use. Regular inspection of these elements is essential to prevent wear and tear.

Maintenance and Repair Tips

Proper care can significantly extend the life of your grooming tool. Cleaning and oiling the moving parts will help maintain smooth operation, while regular checks for loose or damaged components can prevent costly repairs. If you notice a decrease in performance, it’s important to review these key components for potential issues.

How to Identify Key Grooming Tool Components

Recognizing the essential elements of your grooming device is crucial for effective maintenance and repair. Understanding the role of each part allows for easier troubleshooting and ensures your tool continues to perform at its best. By familiarizing yourself with the internal structure, you can spot potential issues before they become serious problems.

Recognizing the Main Functional Elements

The key parts to focus on include the motor, cutting mechanism, and the casing. The motor drives the operation of the device, while the cutting mechanism, usually made up of blades or combs, performs the actual trimming. The casing serves as the outer shell, protecting the internal components from damage and providing the tool with stability during use.

Inspecting for Common Issues

When you examine the tool, check for signs of wear in these core components. The motor may show signs of decreased performance, such as slower operation or unusual noise. The cutting mechanism might become dull or misaligned, leading to inefficient trimming. Lastly, inspect the casing for any cracks or loose parts that could compromise the tool’s function.

Step-by-Step Grooming Tool Assembly Guide

Reassembling your grooming device correctly ensures its longevity and reliable performance. Following a clear, organized approach is essential to avoid any mistakes and ensure that all internal elements are properly fitted. The process involves reattaching key components in the right order, making sure everything is secure and functional.

Assembly Process

Start with these steps for a smooth reassembly:

- Begin by securing the motor back into the housing. Make sure it is aligned properly with the power switch and the internal wiring.

- Next, position the cutting mechanism, ensuring it connects securely to the motor’s drive shaft.

- Attach any additional elements, such as the protective casing, ensuring all screws and clips are tightened and in place.

- Double-check that all components are aligned and moving freely without obstruction.

Final Checks

Before using the device again, perform these essential checks:

- Verify the tool’s stability by gently shaking it to ensure there are no loose parts.

- Test the motor to ensure smooth operation and that it runs without unusual noise.

- Check the cutting mechanism for proper alignment and sharpness.

By following these steps, you can ensure that your device is properly reassembled and ready for use.