When it comes to operating any mechanical device, knowing the components that make it function smoothly is essential. A detailed view of its internal structure can help you identify individual elements and understand how they work together to ensure efficiency. This knowledge is crucial for anyone seeking to enhance their maintenance skills and troubleshoot issues effectively.

Identifying the key elements of your machinery enables you to spot wear and tear, as well as make informed decisions about repairs or upgrades. By gaining insight into the design, you will be better prepared for routine inspections or any unexpected challenges that may arise during usage.

Familiarizing yourself with the functional aspects of each piece allows you to work more confidently with the equipment, ensuring its longevity and optimal performance. Understanding the connections and roles of the various components provides a strong foundation for both novice users and experienced technicians alike.

Understanding Pulsar Generator Components

Every mechanical device is made up of various elements that work together to perform specific functions. These components form the backbone of the system, ensuring it runs smoothly and efficiently. Gaining an understanding of these individual parts helps users navigate maintenance tasks and identify potential issues.

By examining the internal layout, you can see how each element contributes to the overall operation. Some parts are critical for powering the system, while others ensure safety and stability. Recognizing the role of each piece allows for better troubleshooting and repairs, as well as more informed decisions when it comes to upgrades or replacements.

Knowledge of these components not only aids in day-to-day operation but also enhances long-term performance. Regular checks and understanding the function of each part will ensure your equipment continues to serve you reliably, without the need for frequent interventions or costly repairs.

Identifying Key Parts in Generator Diagrams

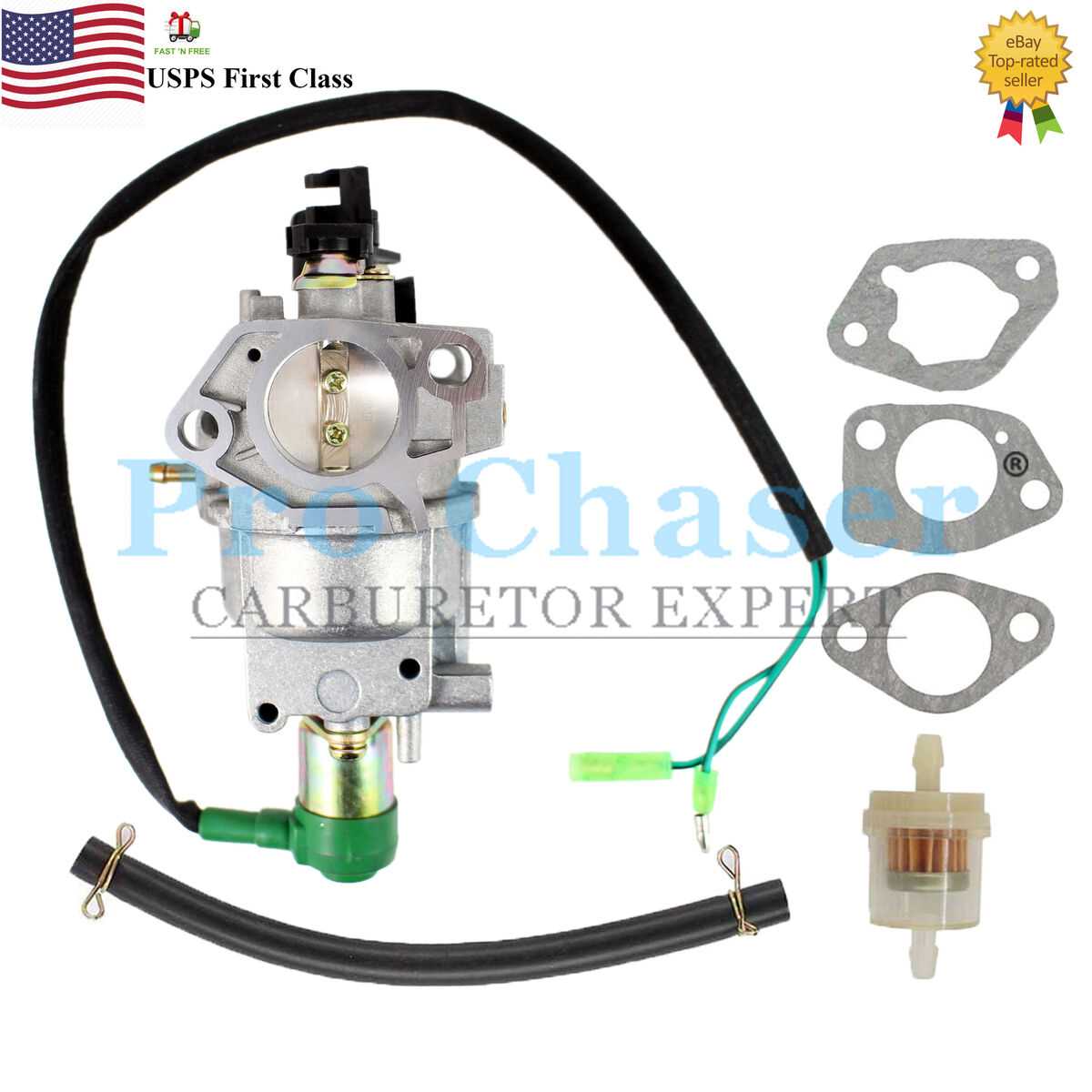

Understanding the layout of any machine requires familiarity with its essential components and how they are represented in visual schematics. These schematics serve as valuable tools to pinpoint the crucial elements that keep the system running effectively. By studying these diagrams, one can identify each component’s role and placement within the whole structure.

Key components are often highlighted or labeled, allowing users to recognize their functions and importance. Some elements are involved in energy production, while others are essential for safety or stability. By knowing how to read these illustrations, you can quickly locate areas that may require attention or troubleshooting.

Mastering the interpretation of such visuals makes it easier to maintain, repair, or upgrade the equipment. Recognizing the individual roles of these vital components allows for a more comprehensive understanding of the system’s overall operation, helping to prevent issues before they arise.

How to Maintain Pulsar Generator Parts

Regular maintenance is essential for ensuring the longevity and efficient operation of any mechanical system. Proper care prevents unexpected breakdowns and keeps all components functioning at their best. By understanding the requirements for routine upkeep, you can easily address minor issues before they develop into costly repairs.

Routine Checks and Inspections

Performing regular checks on critical components is vital to identify wear and tear early. Inspecting the system’s internal elements, such as the wiring, fuel system, and cooling mechanisms, ensures that everything remains in good working condition. Any unusual noises, vibrations, or performance dips should be investigated promptly to avoid further damage.

Cleaning and Lubrication

Maintaining cleanliness and applying proper lubrication to moving parts are crucial steps in preventing premature wear. Dust, dirt, and debris can accumulate over time, affecting efficiency. Regularly cleaning and lubricating the necessary components helps reduce friction and extends the lifespan of essential elements.