When it comes to maintaining your snow clearing equipment, understanding its internal components is crucial for ensuring smooth operation throughout the winter season. Proper knowledge of how each piece works together allows for effective troubleshooting and efficient repairs. Whether you are an experienced user or a first-time owner, familiarizing yourself with the structure of the machine can save both time and money in the long run.

In this guide, we will break down the essential elements of your machine, helping you to identify and address common issues that may arise. Knowing where each component fits and how to replace or repair them is key to keeping your equipment in top working condition. From the engine to the auger assembly, every part plays a vital role in performance.

With this information, you’ll be able to handle basic repairs with confidence, ensuring your equipment remains functional and ready to tackle snowstorms when they arrive.

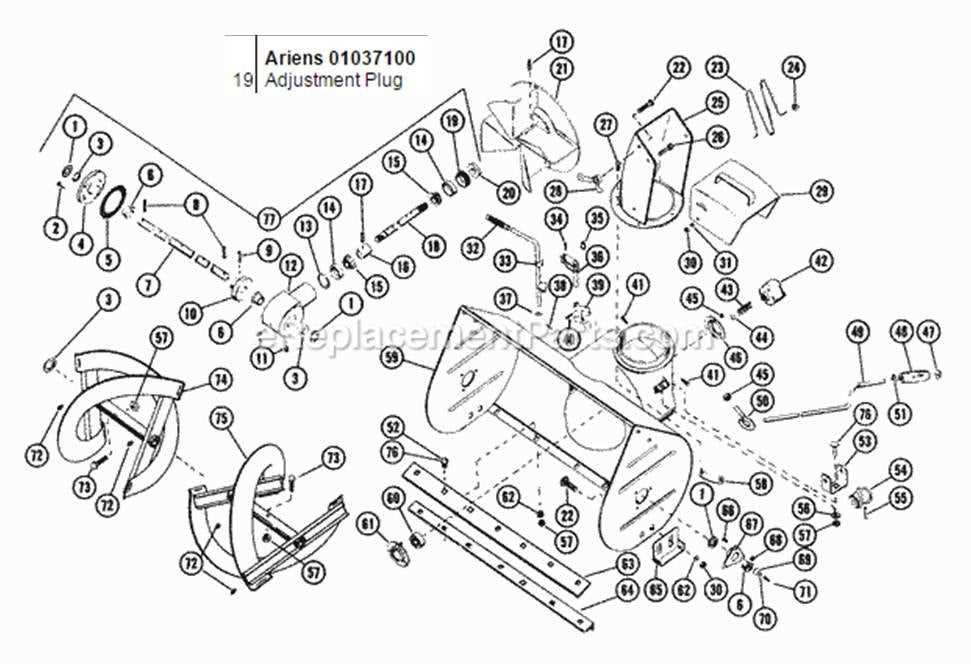

Understanding the Snow Blower Components Layout

To maintain your snow clearing equipment effectively, it’s essential to have a clear understanding of how each individual piece interacts within the entire system. A visual representation that outlines all the key elements of the machine can simplify both troubleshooting and repair tasks. By learning the specific role of each component, users can approach maintenance with greater confidence and efficiency.

Key Elements of the System

Every snow blower consists of several critical sections that work in harmony to ensure optimal performance. These include the engine, the chute assembly, drive components, and other mechanical elements. Familiarizing yourself with these units will help you quickly pinpoint any issues and avoid unnecessary repairs. The layout also provides insight into how the components fit together, aiding in more precise disassembly and reassembly processes.

Locating and Identifying Common Issues

When something goes wrong, knowing exactly where to look can save you valuable time. By referencing a well-organized schematic of the equipment, you can identify potential failures in components such as belts, the auger mechanism, or electrical connections. This understanding allows for quicker fixes and ensures that the equipment is back up and running in no time.

Common Components and Their Functions

Every snow clearing machine is made up of various integral components that work together to achieve optimal performance. Understanding the function of each part ensures efficient operation and helps users identify issues before they become major problems. Below, we will explore some of the most common elements found in snow blowers and their primary roles.

Engine and Power System

The engine serves as the heart of the machine, providing the power needed to drive the auger and wheels. It converts fuel into mechanical energy, which powers the system and allows for consistent performance, even in challenging snow conditions. The power system also includes components like spark plugs, carburetors, and fuel lines that ensure the engine runs smoothly and efficiently.

Auger and Drive Mechanism

The auger is responsible for collecting snow and ice, feeding it into the chute for disposal. It is usually driven by the engine through a belt or gear system. The drive mechanism also includes the traction system, which moves the machine forward, allowing the operator to control speed and maneuverability. Understanding how the auger and drive system work together helps with maintenance and troubleshooting, ensuring proper snow clearing.

How to Replace Snow Blower Components

Replacing damaged or worn components of your snow clearing equipment is essential for keeping it in good working order. Knowing how to properly swap out specific parts can extend the life of the machine and ensure that it operates at peak performance. Below, we will cover the basic steps for replacing key elements, from identification to installation.

Step-by-Step Process for Replacing Key Components

Before starting any replacement process, always ensure the machine is turned off and disconnected from its power source. Begin by identifying the damaged or worn part by referencing the layout. Once located, remove any surrounding components that may obstruct access. This often involves loosening bolts or screws. After the old part is removed, install the new component by carefully aligning it and securing it in place. Make sure everything is tightened properly to avoid further issues.

Common Tools for Replacements

To perform most replacements, you’ll need a basic set of tools, including wrenches, screwdrivers, and pliers. Depending on the complexity of the component, you may also require specialty tools like a torque wrench or puller. Always use the correct tool for each job to avoid damaging surrounding elements or the new part. Having the right tools on hand will make the replacement process smoother and faster.