Maintaining outdoor power equipment can often seem overwhelming, but understanding its structure can make the process easier. Identifying and familiarizing yourself with the key elements of your tool ensures you can handle repairs and maintenance more effectively.

When it comes to efficient operation and durability, knowing how every part interacts is crucial. By breaking down each section, users can approach maintenance with confidence, ensuring longevity and smooth performance over time.

Whether you’re fixing a minor issue or performing a full check-up, understanding the internal setup will save both time and effort. Regular inspections of these crucial components will help prevent larger, more costly repairs in the future.

HL 91 K Overview and Features

The HL 91 K is a versatile and reliable tool designed for a wide range of outdoor tasks. It combines powerful performance with user-friendly features, making it an ideal choice for both professionals and homeowners. Whether you’re trimming hedges, shaping shrubs, or tackling other tasks, this tool offers the precision and efficiency needed for flawless results.

Powerful Engine and Performance

At the heart of this equipment is a robust engine, engineered to handle demanding tasks with ease. The design ensures high efficiency and minimal fuel consumption, allowing for extended operation without frequent refueling. With its ergonomic build, users can work for extended periods without experiencing undue strain, making it perfect for long projects.

Innovative Features for Easy Handling

The HL 91 K boasts several design elements that prioritize comfort and ease of use. The lightweight construction reduces fatigue, while the adjustable working head provides flexibility in reaching various angles. A user-friendly control system ensures effortless operation, even for those less experienced with outdoor power tools.

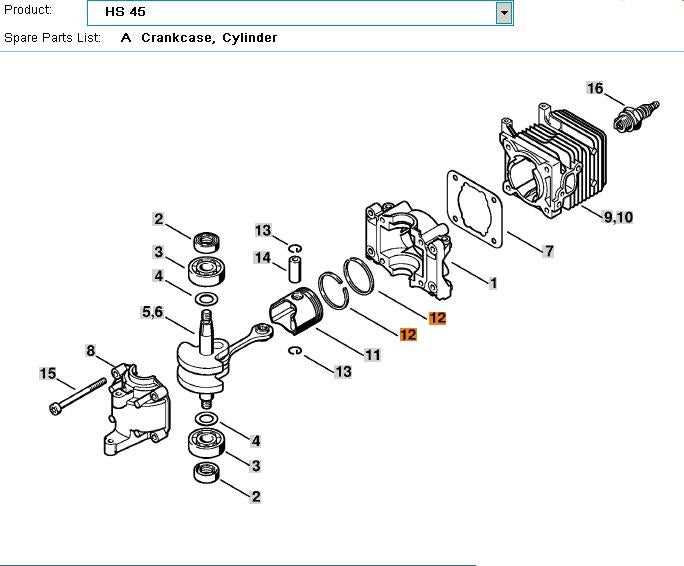

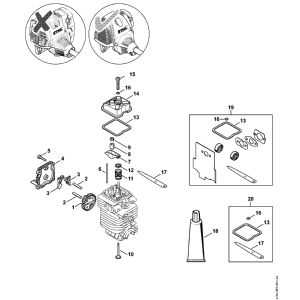

Understanding the Components of HL 91 K

Getting familiar with the internal structure of any tool is essential for performing effective maintenance and repairs. By breaking down the tool into its individual components, users can quickly identify where issues might arise and how to resolve them. A clear understanding of how everything fits together ensures that the tool remains in optimal condition for long-term use.

Key Elements to Know

The primary elements that make up the structure of this equipment are carefully designed for durability and efficiency. Here are some of the crucial sections:

- Engine Assembly: Responsible for the overall power and function.

- Handle and Shaft: Designed for ergonomic comfort and control during use.

- Transmission: Transfers energy from the engine to the working parts.

- Control Mechanism: Allows the user to adjust settings for precise operation.

How Components Interact

Each element of the tool is designed to work together seamlessly. Understanding these relationships is key to diagnosing and addressing issues efficiently. By knowing the role of each component, users can quickly assess the condition of their equipment and make necessary adjustments or replacements.

How to Maintain HL 91 K Effectively

Proper maintenance is crucial for ensuring the longevity and smooth operation of any outdoor tool. By following a regular upkeep routine, you can prevent breakdowns, improve performance, and avoid costly repairs. Keeping your equipment in top shape not only extends its lifespan but also ensures that it works efficiently when you need it most.

Routine Inspection and Cleaning

Regular inspection is key to identifying potential issues early. After each use, thoroughly clean the tool to remove dirt, debris, and moisture, which can cause corrosion or damage. Check for signs of wear, such as frayed wires or loose fasteners, and replace any damaged components promptly. A clean tool operates better and reduces the risk of malfunctions.

Lubrication and Adjustments

Lubricating moving parts is essential to prevent friction and ensure smooth operation. Apply the recommended lubricants to gears and other mechanical components at regular intervals. Additionally, ensure that all adjustments are made according to the manufacturer’s guidelines. Tighten screws and bolts to maintain proper alignment, and regularly check the tension on components to avoid unnecessary strain.