When it comes to maintaining and repairing your hunting gear, having a clear understanding of its individual elements is essential. Knowing how each piece functions and interacts ensures you can troubleshoot, replace, or upgrade parts with confidence. This guide will help you navigate through the complex structure of your gear, providing a clear visual representation and explanation of each component.

Whether you’re assembling a new unit or performing routine maintenance, familiarity with its mechanical layout will save you time and effort. By examining the various sections and their specific roles, you’ll gain insight into the overall design, allowing you to make informed decisions about repairs and upgrades. Understanding these details not only improves performance but also extends the lifespan of your equipment.

Efficient upkeep and quick repairs become much easier when you can identify each part with ease. A comprehensive breakdown is invaluable for any user aiming to get the most out of their gear.

Understanding the Key Components of Your Equipment

Every mechanical system is made up of multiple interconnected elements, each contributing to its overall functionality. Understanding the role of each section allows you to operate, maintain, and repair the system with greater precision. In this section, we’ll explore the key components that make up your device and how they work together to ensure optimal performance.

Key Elements and Their Functions

The core structure includes several critical components that work in harmony. From the main frame to the propulsion system, each piece has a distinct purpose, whether it’s delivering power, providing stability, or ensuring accuracy. Familiarizing yourself with these parts will help you understand how they affect the overall performance of the equipment, from aiming to firing.

Maintenance and Care for Longevity

Proper care and attention to individual elements are essential for keeping everything in peak condition. Regular cleaning, inspection, and occasional replacements ensure that each part functions smoothly and lasts longer. Understanding the layout and operation of the parts makes it easier to spot issues before they become major problems.

Identifying Key Parts in the Diagram

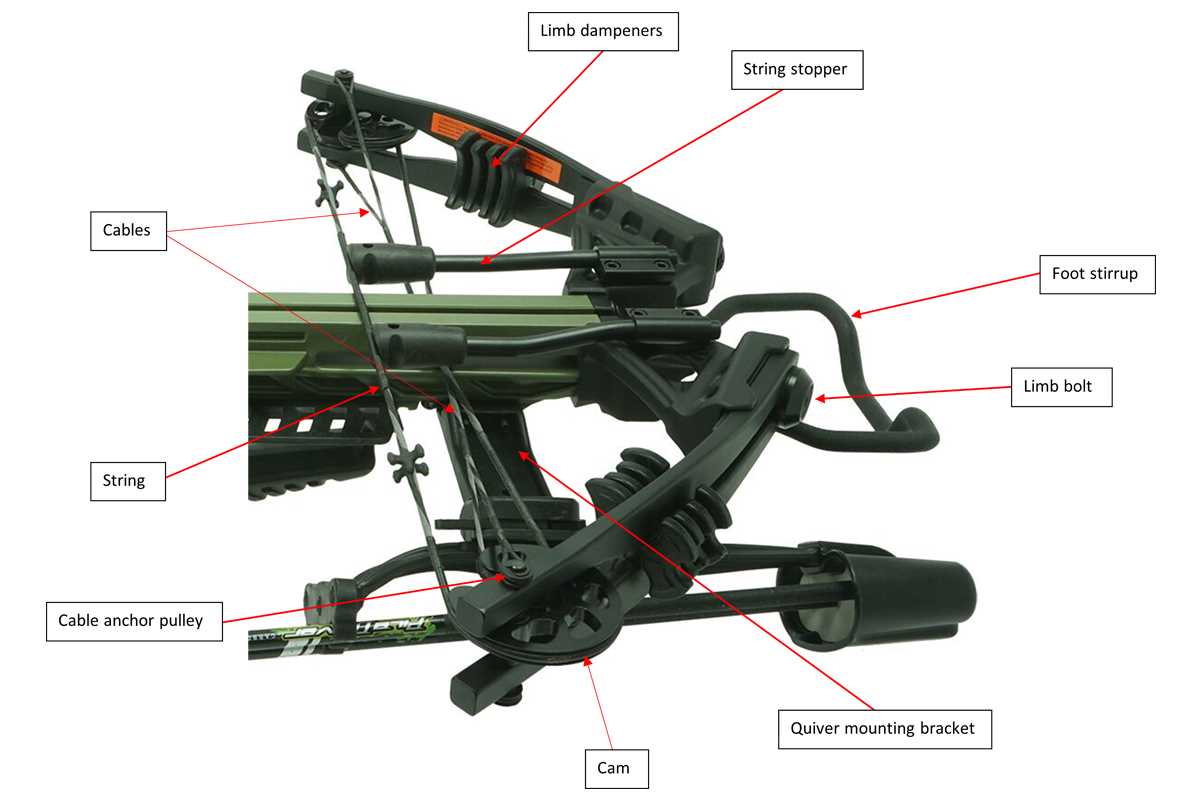

To properly understand your equipment’s layout, it is essential to recognize each individual element and its role within the system. A detailed visual guide can help you identify components quickly, enabling effective maintenance and troubleshooting. In this section, we’ll break down the major sections and explain how each contributes to the overall functionality.

| Component | Description |

|---|---|

| Frame | The main structure that holds all other parts in place and provides stability. |

| String | The tensioned cord responsible for transferring energy to the projectile. |

| Trigger Mechanism | The mechanism that releases the tensioned string to propel the projectile. |

| Scope | An aiming device that helps improve accuracy when targeting. |

| Stock | The part held against the shoulder to stabilize the equipment during use. |

Understanding these key components will allow you to better care for your equipment, ensuring longevity and efficient performance. Identifying each part with ease will also make the process of repair or replacement simpler, as you’ll be able to pinpoint exactly where attention is needed.

How to Read a Parts Breakdown

Understanding a breakdown of your equipment’s components is essential for both repairs and assembly. A well-organized guide offers clear labels, visual references, and detailed explanations, making it easier to identify each section. By learning how to interpret these illustrations, you can quickly determine which parts are necessary for maintenance or replacement.

Step 1: Begin by identifying the overall layout of the system. Each part is often numbered or labeled to indicate its place within the structure. This allows you to trace its connections and understand how it interacts with other elements.

Step 2: Pay attention to the sectional views. These provide a closer look at individual components, showing how they fit together or operate within the system. This is especially useful for more complex parts that require specific alignment or adjustment.

Step 3: Lastly, note any maintenance or installation instructions provided alongside the breakdown. These tips often highlight common issues, helping you avoid mistakes during assembly or repair processes. With a clear understanding of the diagram, you can handle any troubleshooting task efficiently.

Step-by-Step Breakdown of Each Component

Understanding the function and installation of each component is vital for effective usage and maintenance. A step-by-step guide will help you break down the essential elements, ensuring you are familiar with each section before performing any adjustments or repairs. By carefully following the instructions, you can troubleshoot or upgrade your equipment with precision.

Frame and Structure

The foundation of your device consists of the main body and frame. This section holds all other elements in place, providing stability during operation. It is crucial to inspect the frame regularly for any signs of wear or damage. The integrity of the frame directly impacts the performance and safety of the entire system.

String and Propulsion Mechanism

The string plays a critical role in transferring energy to the projectile. Proper tension and maintenance of the string are essential for consistent firing power. Ensure that the string is correctly aligned with the rest of the mechanism and replace it when needed to maintain accuracy and reliability.

By understanding these steps and their corresponding components, you can perform maintenance tasks confidently and extend the lifespan of your equipment. Each section, when properly cared for, ensures optimal performance in the long run.

Maintaining Your Equipment Effectively

Proper upkeep is essential to ensure your gear performs reliably over time. Regular maintenance helps prevent breakdowns and enhances its lifespan. By following a consistent maintenance routine, you can avoid costly repairs and improve overall efficiency. Here are key practices to keep your equipment in top condition.

- Regular Cleaning: After each use, clean the components to remove dirt, moisture, and debris. This helps prevent rust and damage.

- Inspect for Wear: Periodically check for signs of wear or damage, especially on moving parts. Replace any components that show significant wear to avoid malfunction.

- Lubrication: Apply lubricant to the necessary parts to ensure smooth movement. Over time, friction can wear down components, and lubrication minimizes this risk.

- Tension Adjustment: Ensure the tension on critical elements is correct for optimal performance. Too much or too little tension can affect accuracy and power.

By following these maintenance tips, you’ll ensure your equipment remains functional and reliable. Regular attention to these aspects can significantly extend its lifespan and prevent unexpected issues.