Maintaining your garden tools can significantly improve their efficiency and lifespan. Whether you are handling a trimmer or a similar outdoor tool, knowing the internal components is essential for proper care and repairs. This knowledge ensures you can tackle any issues that arise and replace worn-out elements with ease.

By understanding how each section functions, you can make more informed decisions about fixing or upgrading your equipment. Familiarity with these mechanisms also helps prevent common malfunctions and reduces the need for costly professional repairs.

In this guide, we will explore how to identify key elements in your tool and how to use this information for effective maintenance. Recognizing the most crucial parts will help you achieve optimal performance for years to come.

Understanding Lawn Tool Components

Every piece of outdoor equipment consists of a variety of elements working together to ensure smooth operation. Identifying and understanding these components is crucial for maintaining the tool’s efficiency and preventing malfunctions. Knowing how each part contributes to the overall function allows for more precise repairs and replacements, ultimately extending the life of the equipment.

Main Mechanisms of Your Tool

The primary functions of these machines are powered by key components, such as the engine, handle assembly, and trimming mechanism. The engine is responsible for providing the necessary power, while the handle assembly ensures ease of use. The cutting mechanism, often featuring rotating lines or blades, directly impacts the tool’s performance in handling vegetation.

Commonly Replaced Parts

There are several components that often wear out over time and require replacement. These include the cutting head, fuel system elements, and spark plugs. Regular inspection of these parts is necessary to identify wear and prevent damage to the entire machine. By keeping a close eye on these elements, users can avoid significant breakdowns and costly repairs.

How to Read a Lawn Tool Blueprint

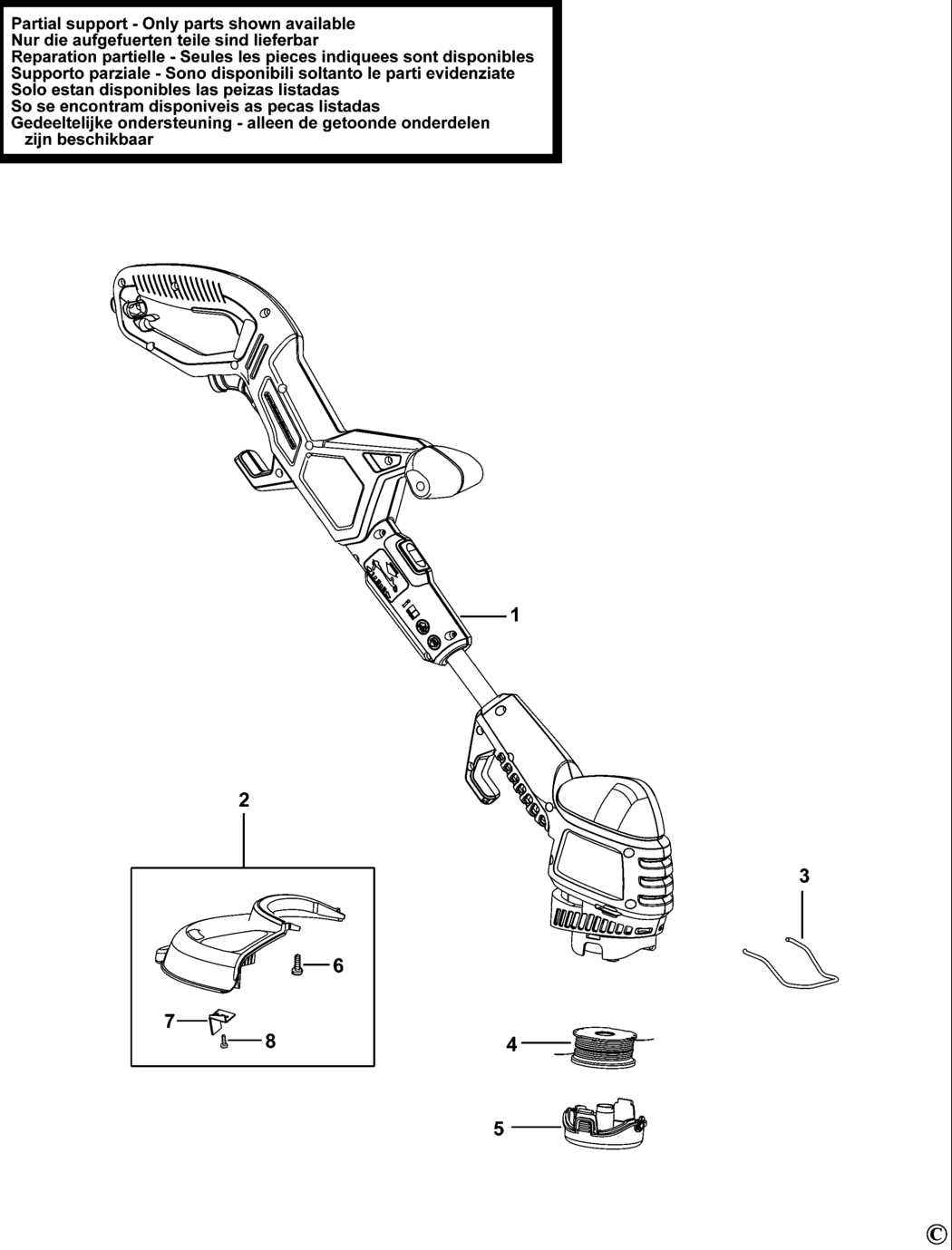

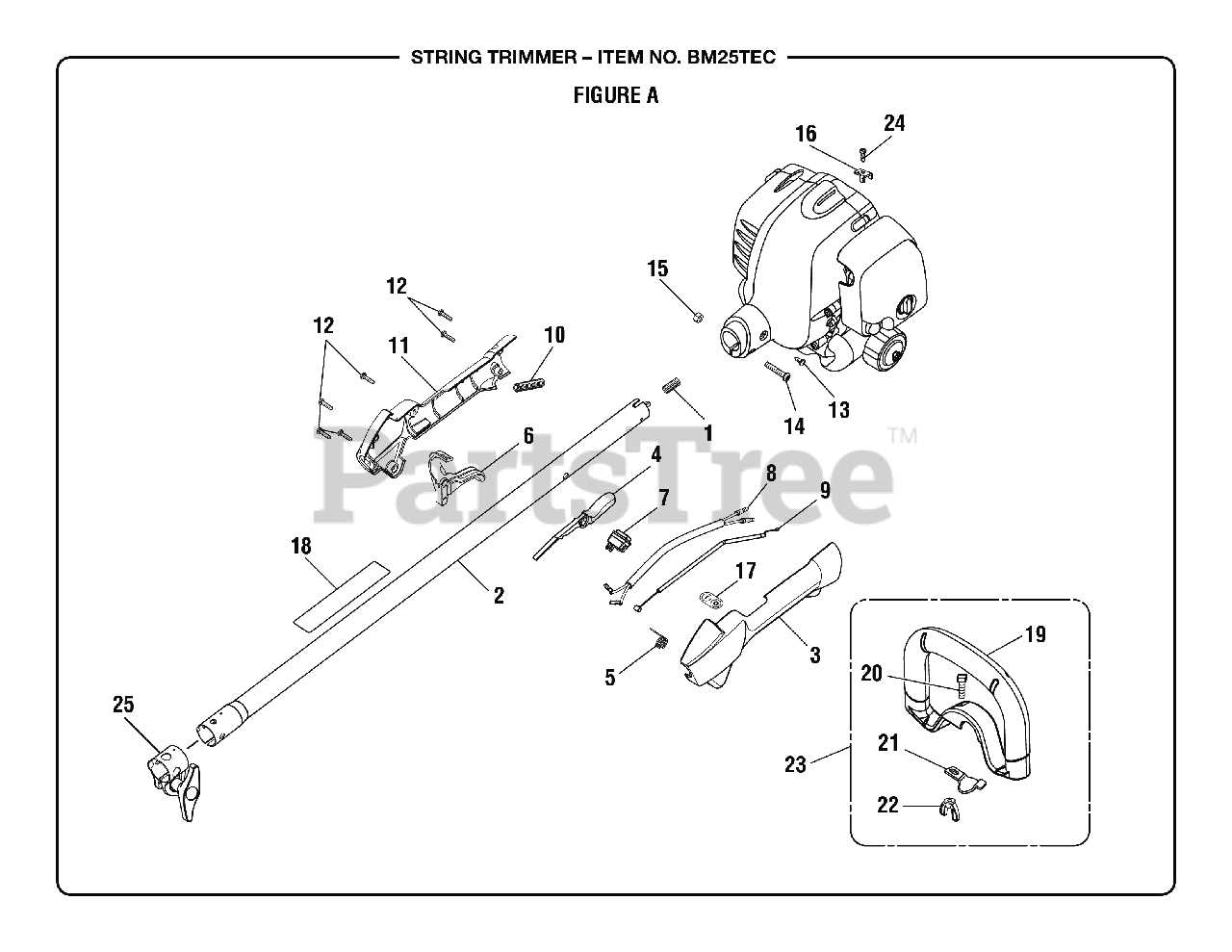

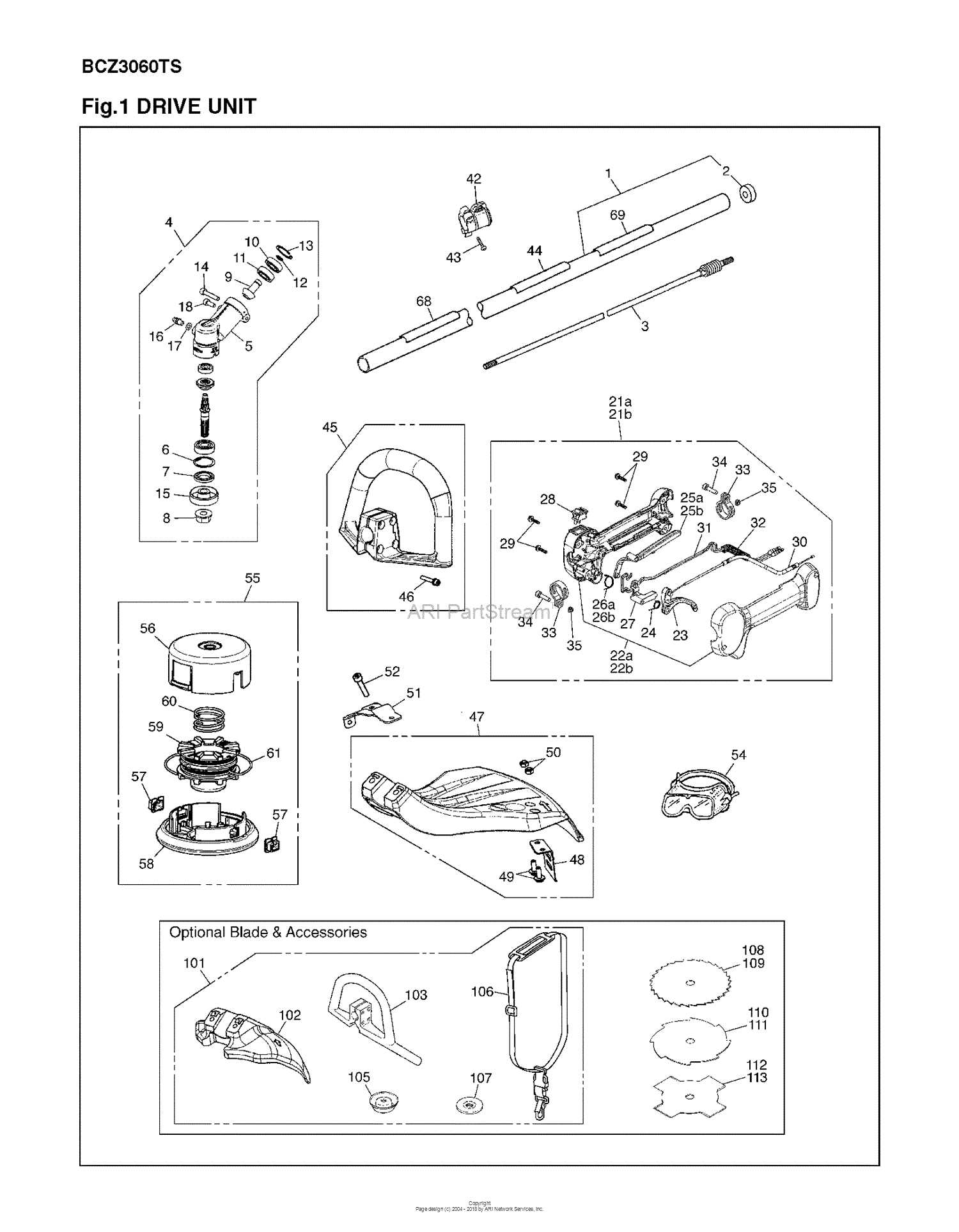

Understanding a blueprint for your outdoor equipment is essential for identifying and troubleshooting issues. These blueprints visually represent how all the internal elements are arranged and how they interact. By learning how to interpret these illustrations, you can pinpoint specific areas that may need maintenance or replacement.

When looking at a tool’s blueprint, it’s important to start by recognizing the key sections, such as the engine, handle assembly, and cutting mechanism. Each part is usually labeled, allowing you to understand where each component fits within the whole system. Pay attention to any lines or arrows that indicate movement or connections between parts.

Reading the labels is one of the most crucial steps in understanding how a diagram works. Parts are often marked with unique identifiers or numbers, which correspond to a list or key. These numbers help you identify the exact part needed for repairs or upgrades.

Recognizing the flow is another important aspect. Many diagrams also show how the different components function together, from power distribution to the cutting motion. This allows you to get a sense of the tool’s overall performance, helping you understand what might cause malfunctions or inefficiencies.

Common Lawn Tool Components for Replacement

Over time, certain elements of your outdoor equipment may wear out and need to be replaced. Regular maintenance and timely replacements can ensure that your tool continues to perform at its best. Knowing which parts are most likely to require replacement will help you keep your equipment in optimal working condition.

Essential Replacement Components

Some of the most commonly replaced elements include the cutting head, spark plug, and fuel system components. The cutting head, which is responsible for trimming vegetation, can become dull or damaged over time, requiring a replacement. The spark plug, crucial for engine ignition, is another frequent replacement item due to wear. Additionally, parts within the fuel system, such as filters and lines, can degrade and must be replaced to ensure proper fuel flow and engine function.

Components to Watch For Damage

In addition to the essential items, there are other components that may experience damage and need replacement, such as the drive shaft and recoil starter. These parts are vital for the tool’s operation but are often overlooked. Regular inspection of these areas will help prevent more significant issues and avoid unnecessary downtime.