Maintaining and repairing high-performance cleaning machines can be a challenge without a clear understanding of their inner workings. Knowing the individual elements that make up these machines is essential for proper care and efficient operation. Whether you’re looking to fix an issue or perform routine maintenance, having access to a comprehensive guide of the machine’s components can save both time and effort.

In this section, we will explore the key components that make up these powerful devices, offering valuable insights into their functions and how they interact. With the right knowledge, users can easily troubleshoot problems, replace worn-out components, and ensure the longevity of their equipment. Understanding how each part contributes to the overall performance is critical for achieving optimal results.

Understanding the Components of High-Pressure Cleaning Equipment

When working with powerful cleaning machines, it’s essential to understand how each component contributes to its overall performance. These devices are made up of several interconnected parts, each designed to perform a specific task. Knowing how they function together allows for better maintenance, quicker problem-solving, and more effective use. In this section, we will take a closer look at the key elements that make up these machines, providing a foundation for more efficient use and care.

Core Elements of the Machine

The engine, the heart of the system, powers the entire unit. It is responsible for driving the pump, which in turn generates the necessary force for the water flow. Additionally, various valves and hoses are critical for directing the flow of water and ensuring that the right amount of pressure is applied. Understanding how these components work together is crucial for diagnosing issues and ensuring that everything is functioning optimally.

Important Support Components

In addition to the core functional elements, other components such as the nozzle, spray gun, and filtration system play an important role in achieving desired results. These parts help regulate the output, ensuring the correct distribution of water pressure. Regular inspection and maintenance of these support elements can prevent potential damage and improve the efficiency of your cleaning tasks.

How to Read the Equipment Component Layout

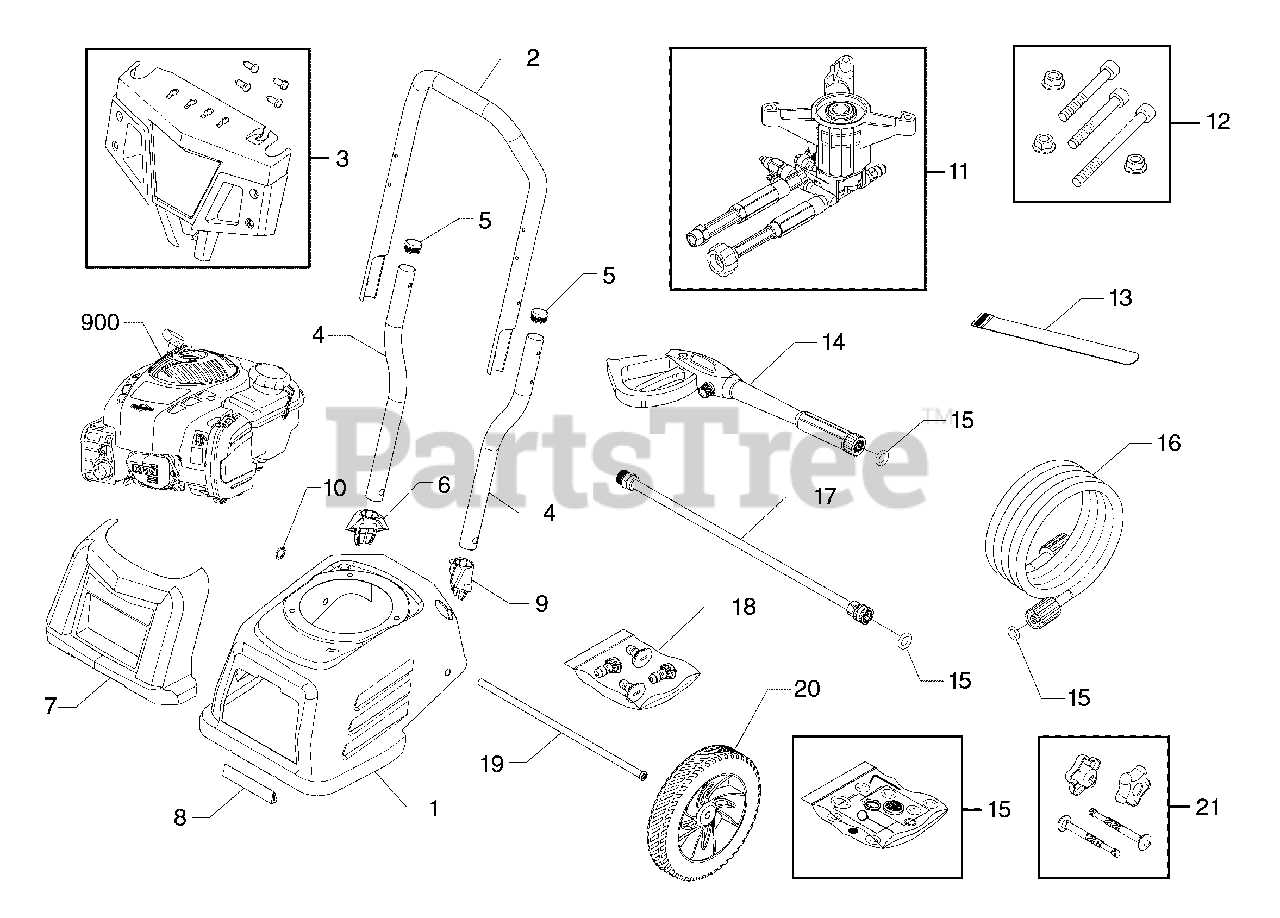

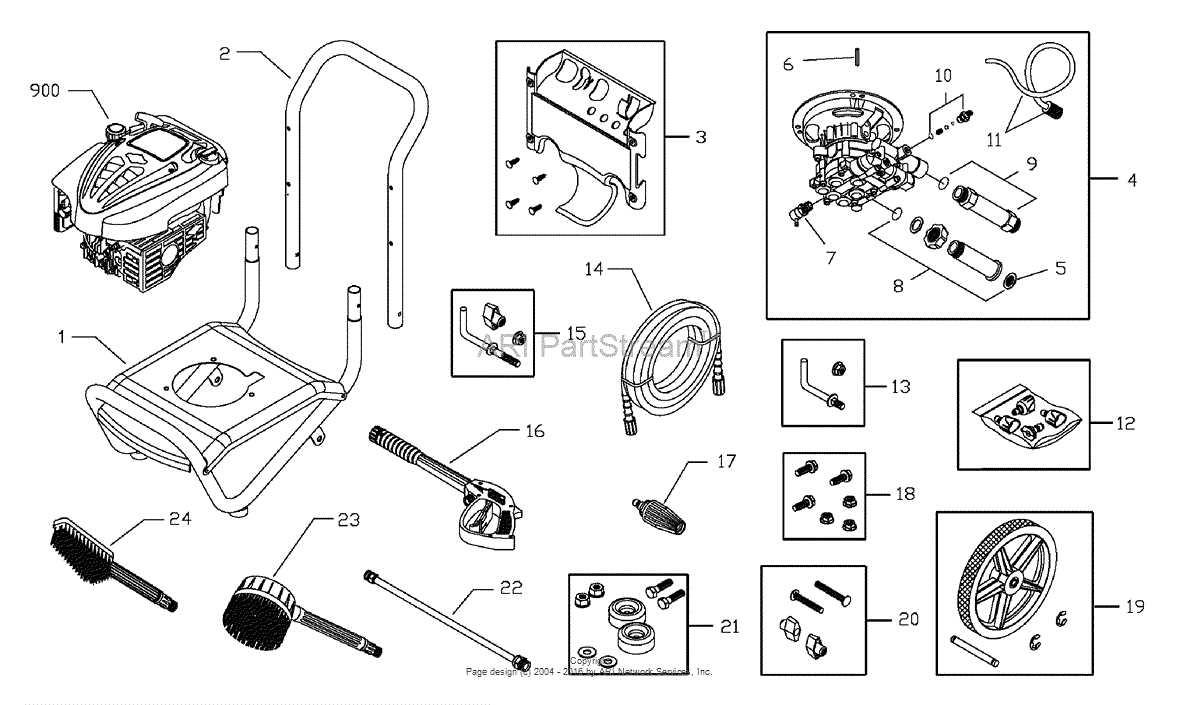

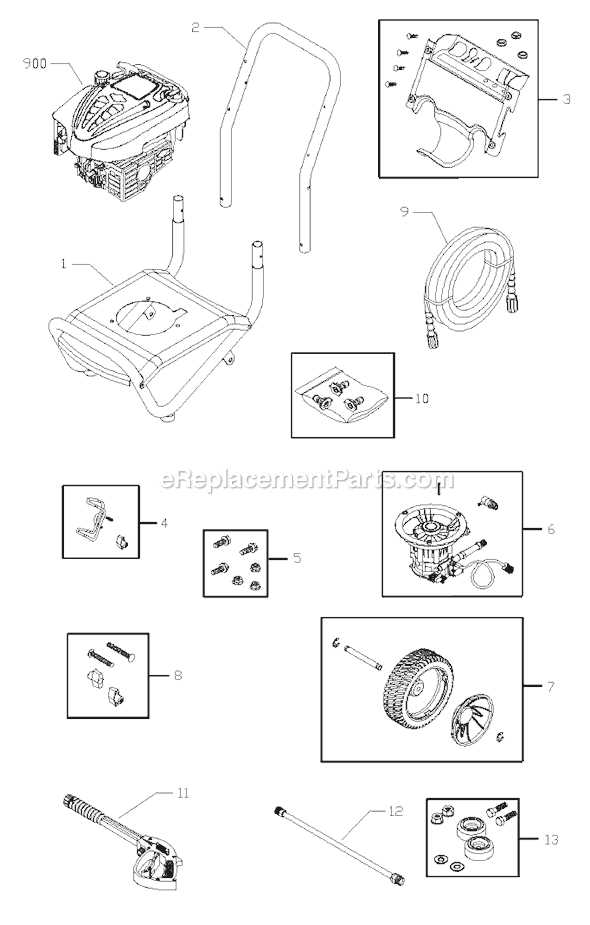

Understanding the layout of an equipment’s components is vital for performing repairs and maintenance. A detailed schematic provides a clear illustration of how each part fits together and operates within the system. Being able to read and interpret these diagrams can save you time when troubleshooting and allow for more efficient repairs. This section will guide you through the process of understanding the component layout to ensure effective machine upkeep.

Interpreting the Visuals

The first step in reading a component layout is to familiarize yourself with the visual representation. Most schematics use standardized symbols to depict the different parts of the equipment. These symbols are often labeled with part numbers or names, which can help you identify each component quickly. Pay attention to the flow of connections, as it shows how water or air moves through the system, ensuring that everything is working in harmony.

Identifying Key Components and Their Roles

Once you’ve understood the layout, focus on identifying the most crucial components. These include elements like the engine, pump, and spray assembly. Not all parts may be immediately obvious, but each will play a specific role in the machine’s operation. Understanding their functions within the system allows for more accurate diagnosis of issues and easier identification of replacement parts when necessary.

Common Issues and Fixes for High-Pressure Cleaning Equipment

Even the most reliable high-performance cleaning machines can experience occasional problems. Understanding the most common issues and how to address them can save both time and money. From power loss to malfunctioning parts, recognizing the signs early can prevent further damage and restore your equipment to peak performance. This section covers the typical problems users face and their simple solutions.

Loss of Power or Low Output

If the equipment is not delivering the expected output or has reduced power, it may be due to a blocked nozzle or clogged filters. Over time, dirt and debris can accumulate, restricting the flow of water. Regularly cleaning and inspecting the nozzles and filters ensures consistent performance. In some cases, the issue may also stem from a worn-out pump, which may require replacement or servicing.

Water Leakage or Disconnection

Water leakage is another common issue, often caused by worn seals, loose connections, or cracked hoses. To fix this, check all hoses and fittings for any visible damage. Make sure that all connections are tightly secured and replace any damaged seals. It’s important to inspect the equipment periodically to avoid more significant leaks that can cause long-term damage.