Understanding the inner workings of an engine is crucial for effective upkeep and repair. Knowing the various elements that make up the system allows for better management, faster fixes, and a longer operational lifespan. A clear representation of these components helps anyone involved in maintenance tasks to approach repairs with confidence.

Whether you’re an experienced technician or a DIY enthusiast, a visual reference of engine components simplifies the identification of issues. With a clear overview, it’s easier to pinpoint worn or damaged pieces that need replacing or servicing, ultimately improving the engine’s performance.

Accurate knowledge of engine components is essential for making informed decisions during repairs. Being familiar with each part’s function ensures that you handle replacements or adjustments correctly, preventing further complications and maintaining optimal efficiency.

Understanding the Engine Components

To ensure optimal performance, it is essential to familiarize yourself with the key elements that make up an engine. Each individual piece plays a specific role in the overall functionality, from generating power to controlling the system’s efficiency. Recognizing the structure allows for easier diagnosis and repair when issues arise.

The core components work together harmoniously, contributing to the seamless operation of the system. For maintenance purposes, it’s important to know how these elements interact, as this understanding can help identify when something has worn out or malfunctioned. Proper recognition of the system’s layout helps in replacing or servicing the correct components without disrupting the engine’s balance.

Having an in-depth knowledge of each piece’s function also aids in preventing potential problems. Regular inspection and proper maintenance of these essential components will keep the system running smoothly, extending its longevity and minimizing unexpected breakdowns.

How to Read the Components Overview

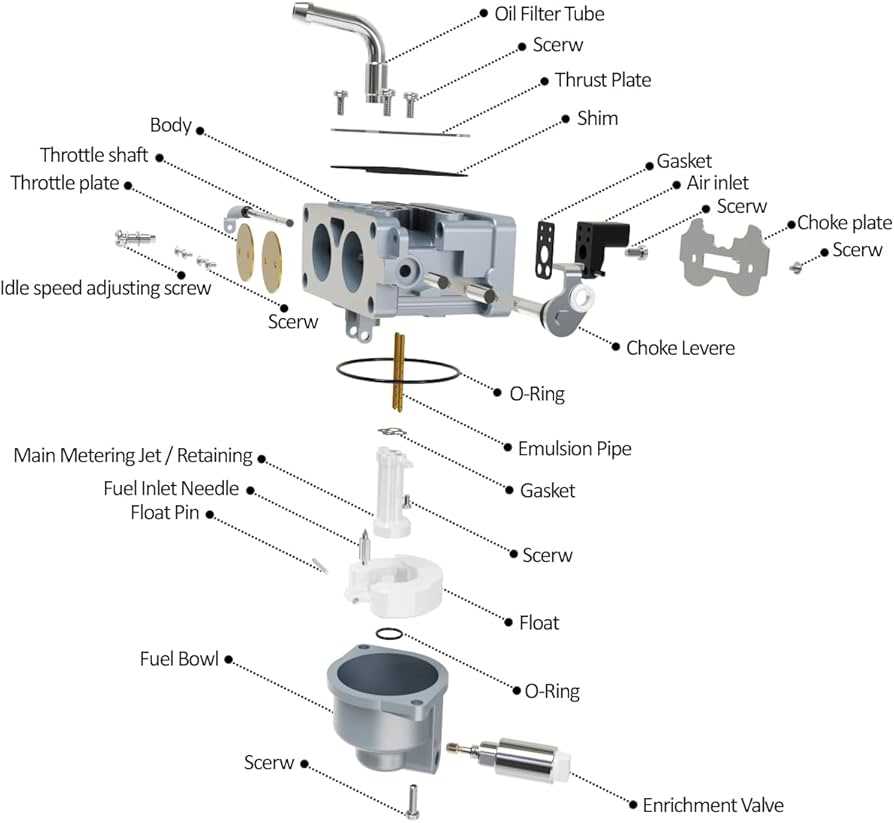

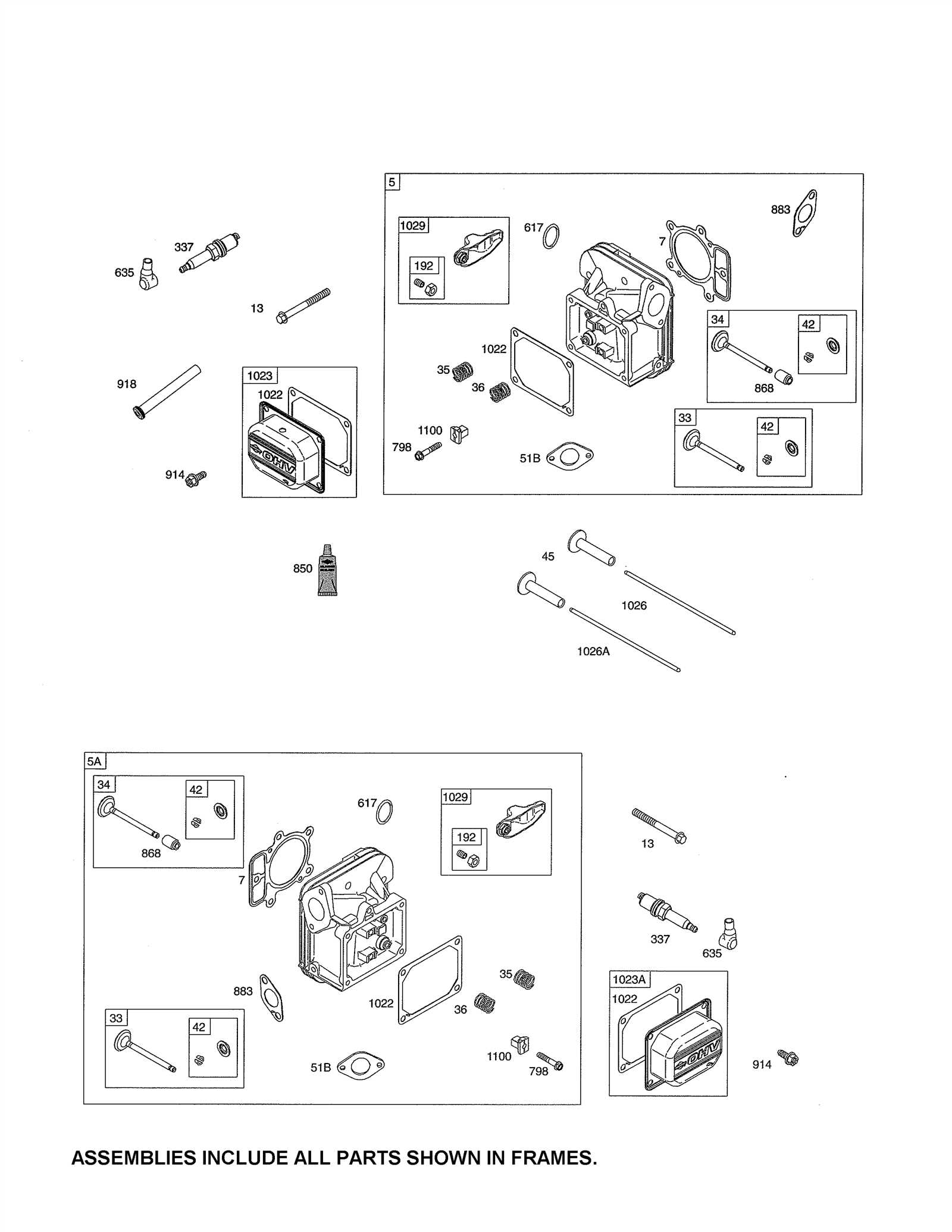

Reading an engine component illustration can seem overwhelming at first, but with the right approach, it becomes a valuable tool for identifying and understanding each section of the machine. By carefully analyzing the visual guide, you can quickly locate specific elements and gain insights into their placement and function within the system.

Key Elements to Focus On

- Labels: Each section is typically labeled with a unique reference number, which corresponds to a detailed description or list of specifications.

- Grouping: Components are often grouped by their function or location within the engine, such as fuel-related or mechanical parts.

- Orientation: Pay attention to the orientation of the components, as the way they are positioned in the diagram may indicate how they fit together in the actual assembly.

Interpreting the Diagram Effectively

Once you have identified the key components, cross-reference them with the corresponding list or description to gain a deeper understanding of their function. This will help when you’re replacing worn parts or diagnosing issues, as you’ll know exactly which elements need attention. Always take the time to compare the visual guide with the actual engine setup to ensure accurate interpretation.

Common Issues and Part Replacements

Engines, like any complex machinery, often experience wear and tear over time. Understanding the typical problems that arise and knowing how to address them through component replacement is essential for maintaining optimal performance. By recognizing the signs of malfunction early, you can prevent more significant damage and extend the life of the system.

Typical Problems

- Fuel System Blockages: Clogged fuel filters or lines can restrict fuel flow, leading to poor performance or engine failure. Regular cleaning or replacing the filter can solve this issue.

- Worn-out Seals: Over time, seals can become brittle or cracked, allowing air or fuel leaks. This can result in inefficient operation and may require replacing seals to restore proper functionality.

- Ignition System Failures: A faulty spark plug or ignition coil can prevent the engine from starting. Inspecting and replacing these parts ensures smooth ignition and reliable performance.

Replacing Faulty Components

When you identify a faulty component, it’s crucial to use the correct replacement to ensure compatibility and efficient operation. Always consult the system’s reference materials to confirm the appropriate replacement for each part. By replacing worn components in a timely manner, you can prevent further issues and keep the engine running smoothly for longer periods.