Every tool consists of multiple elements working in harmony to deliver optimal performance. Whether you’re maintaining or repairing your chainsaw, understanding the layout of its components is essential for proper care. A clear overview of each part allows you to identify problems, plan repairs, and ensure your tool functions at its best for years.

Proper maintenance requires knowing how the different elements interact within the machinery. By breaking down these components, it becomes easier to pinpoint potential issues and ensure everything is in top shape. Recognizing the function of each piece is the first step to mastering care and repair procedures.

Familiarity with the arrangement helps when it’s time to replace worn-out components or perform an upgrade. Understanding how parts fit together enhances troubleshooting, making the entire process more efficient. With the right knowledge, even complex repairs become manageable, ensuring your chainsaw operates smoothly and reliably.

Understanding Chainsaw Components

To effectively maintain or repair a tool, it’s crucial to have a solid grasp of how its various elements work together. Every component plays a specific role, ensuring smooth operation. By becoming familiar with the layout and function of each part, you’ll be better equipped to diagnose issues and perform necessary repairs. A deeper understanding of these components leads to more efficient troubleshooting and longer-lasting equipment.

Key Functional Elements

- Engine: The heart of the machine, responsible for generating the power needed for operation.

- Fuel System: Comprising the tank and lines, it delivers the required fuel to the engine.

- Ignition System: Includes the spark plug and related parts, essential for engine startup.

- Chain Drive: This system transfers energy from the engine to the cutting chain, allowing it to rotate.

How Components Work Together

Each element of the tool works in coordination with the others to ensure smooth operation. The engine provides power, while the fuel system ensures a steady supply of energy. The ignition system gets the engine running, and the chain drive translates this power into movement. Understanding how these elements interact is vital for proper maintenance and repair.

Essential Parts for Maintenance and Repairs

To ensure your tool remains in top condition, certain components are crucial for regular upkeep and efficient repairs. Knowing which parts require the most attention helps prevent damage and extends the lifespan of your equipment. These essential components are not only key to maintaining functionality but also serve as the first points of focus when troubleshooting performance issues.

Critical Components for Upkeep

- Air Filter: Keeps debris and dirt from entering the engine, ensuring smooth operation and reducing wear on internal parts.

- Fuel Filter: Prevents contaminants from entering the fuel system, which could cause clogging or inefficient fuel delivery.

- Chain: Regularly checking and replacing the cutting chain ensures proper cutting efficiency and safety.

- Bar: A key part of the chain assembly, it requires periodic maintenance to avoid uneven wear or damage.

Parts to Replace Regularly

Certain elements wear out over time and need to be replaced regularly to maintain peak performance. These components include spark plugs, fuel lines, and gaskets. Ignoring their condition can result in poor performance and even system failures, making timely replacement a critical step in the maintenance process.

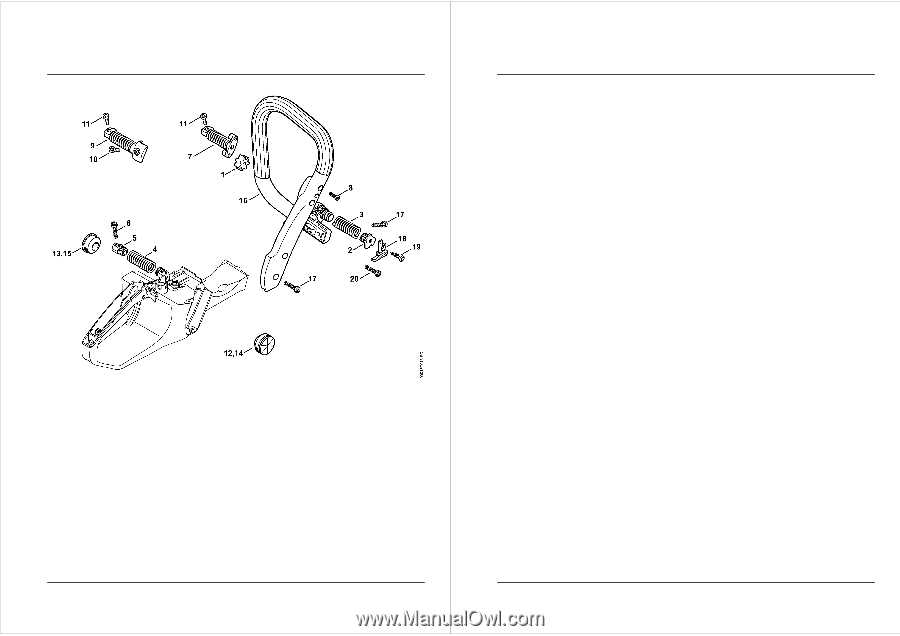

How to Read the Parts Breakdown

Understanding a breakdown of components can be a crucial step in maintaining and repairing equipment. These visuals provide a clear representation of how each part fits together, making it easier to identify issues and determine what needs attention. By learning to read these schematics, you can improve your troubleshooting and make informed decisions about repairs or replacements.

Identifying Components on the Diagram

Each part is usually labeled with a specific number or code. These labels correspond to descriptions or lists that detail the function and specifications of each item. Pay close attention to the placement of these numbers as they often show how parts interact with others in the system.

Understanding Connections and Assembly

Connections between parts are often illustrated with lines or arrows, helping to visualize how components work together. This is especially important when disassembling or reassembling the system, as understanding the flow of energy and movement ensures everything is placed correctly.

Interpreting the Layout and Labels

Understanding how to interpret the visual layout and corresponding labels is essential for proper equipment maintenance. These illustrations provide a detailed map of the internal structure, allowing you to easily identify and reference different components. The key to reading them effectively lies in understanding how the labels correspond to the parts and their functions within the overall system.

Labeling System

The labels on these breakdowns are typically numbered or color-coded to indicate specific components. Each label links to a detailed description of the part, such as its size, material, and purpose. This system helps identify what each element is and how it interacts with others within the tool.

Understanding the Layout

The layout often arranges the components in a logical order, usually starting from the core or most central parts, then branching outwards. This allows you to follow the sequence of parts and their connections easily.

| Label | Component | Description |

|---|---|---|

| 1 | Engine Housing | The protective outer shell of the engine |

| 2 | Fuel Tank | Holds fuel for the engine, ensuring constant supply |

| 3 | Chain Drive | Transmits power from the engine to the cutting mechanism |

Common Issues and Replacement Parts

Over time, tools can experience wear and tear, leading to performance issues or even complete failures. Recognizing common problems early on allows for timely replacements, which helps maintain efficiency and prolong the tool’s lifespan. Identifying the right replacement components ensures the tool continues operating as expected.

Common Problems

- Fuel Delivery Issues: Clogged fuel lines or a malfunctioning fuel filter can hinder proper fuel flow, causing the engine to run inefficiently or fail to start.

- Chain Dysfunction: A dull or broken chain can significantly affect cutting performance. Regular sharpening or replacement is essential for smooth operation.

- Starting Problems: If the engine fails to start, the issue may be with the ignition system or the spark plug, which may need cleaning or replacing.

Replacement Components

Replacing worn or faulty components is critical to maintaining optimal performance. Some of the most commonly replaced parts include:

- Fuel Filter: Helps maintain proper fuel flow by filtering out impurities.

- Air Filter: Prevents debris from entering the engine, ensuring smooth performance.

- Chain and Bar: These components should be replaced regularly to ensure proper cutting efficiency.