Efficient maintenance of heating systems requires a solid understanding of their internal mechanisms. Knowing the individual elements and how they interact is essential for troubleshooting and ensuring optimal performance. When dealing with complex units, familiarity with their structure can make repairs or upgrades much easier and more efficient.

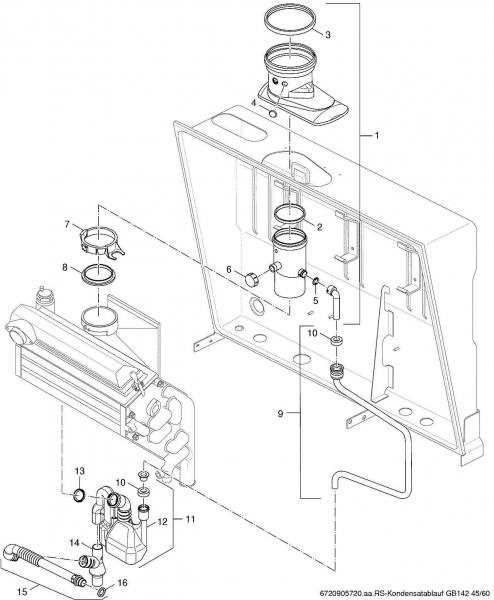

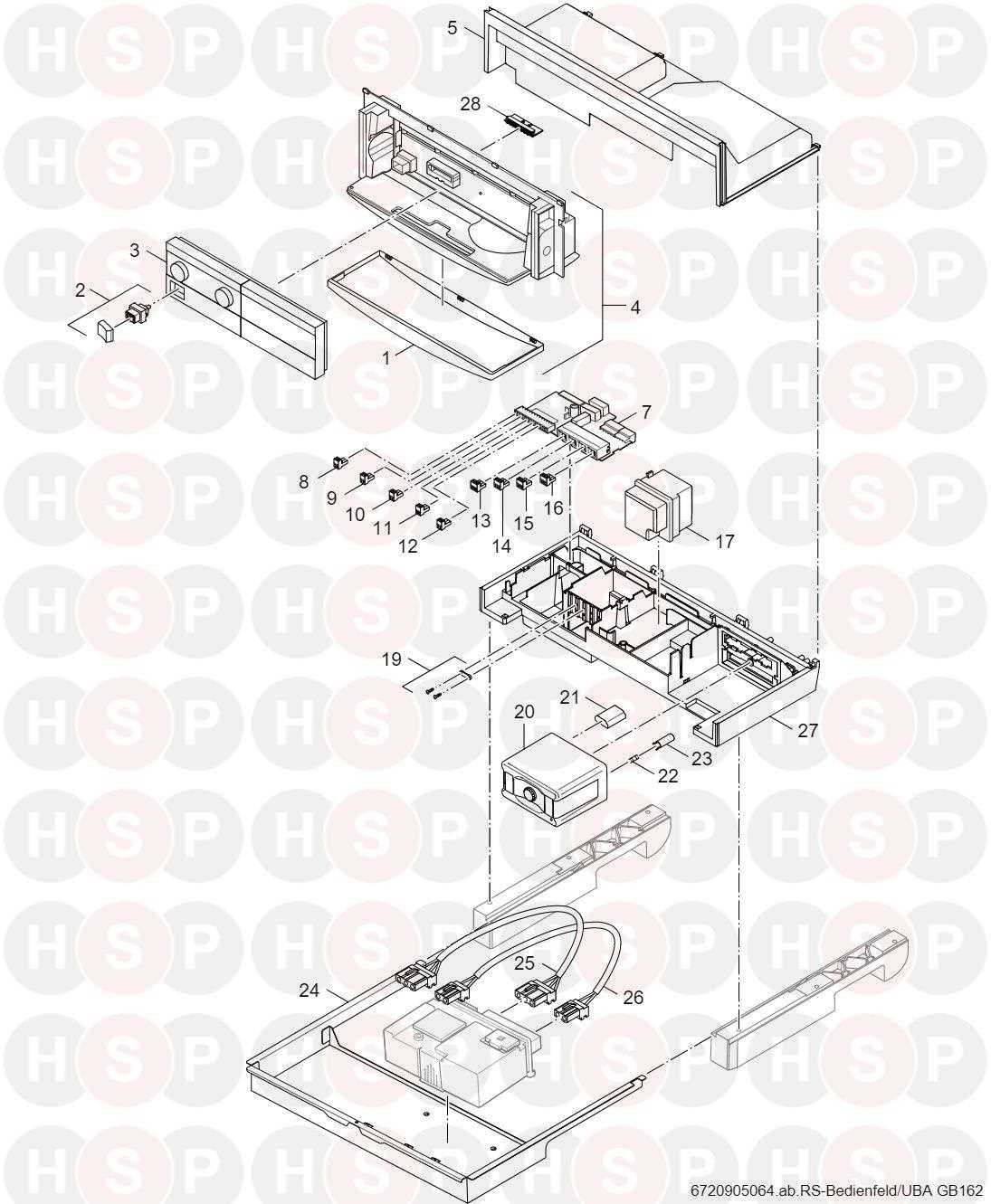

Having access to a detailed blueprint of a heating unit’s components is crucial for anyone performing maintenance. It helps technicians and homeowners alike identify specific parts, understand their roles, and address issues quickly. With clear visual references, you can pinpoint problems and carry out repairs without unnecessary guesswork.

In this guide, we’ll provide insights into the key components of these systems, focusing on their layout, functionality, and how they contribute to overall performance. Whether you’re a professional technician or a homeowner, a comprehensive understanding will enable you to make informed decisions when it comes to system care and upkeep.

Understanding the Buderus GB142 Parts Layout

Effective operation and maintenance of heating systems rely on a clear understanding of their internal structure. Each component plays a specific role in ensuring the unit runs smoothly and efficiently. A detailed overview of the key elements, their placement, and their interactions helps users and technicians perform repairs and maintenance more effectively.

Main Components and Their Functions

The heart of any heating system is its array of interconnected components. Each element, from the combustion chamber to the heat exchanger, has a specific function that contributes to the overall operation. Understanding these functions allows for better diagnosis of any issues that may arise, ensuring repairs are targeted and effective.

Layout and Accessibility for Maintenance

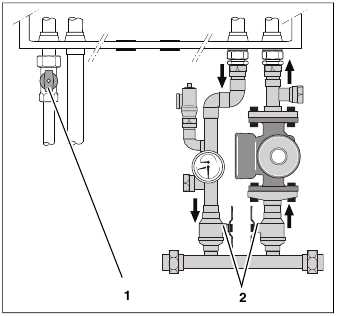

Knowing the layout of the internal components is essential for anyone tasked with maintaining or servicing the system. The arrangement ensures that each part can be accessed when needed, allowing for quick fixes or upgrades. A good understanding of the layout minimizes downtime and prevents unnecessary disruption to the system’s operation.

Key Components of the Buderus GB142 Boiler

Heating systems consist of various essential elements that work together to provide warmth and hot water. Each component is designed to fulfill a specific function, and understanding them can help users ensure proper functioning and make informed decisions about maintenance and repairs.

Combustion Chamber

The combustion chamber is where fuel is burned to generate heat. Its efficiency is crucial for the overall performance of the system, as it directly impacts energy output. A well-maintained chamber ensures optimal combustion and minimizes waste.

Heat Exchanger

The heat exchanger transfers the heat generated in the combustion process to the water circulating through the system. This component plays a vital role in ensuring that the heating system is efficient and can deliver consistent warmth without excess energy consumption.

Burner

The burner is responsible for initiating the combustion process. It precisely controls the flow of fuel and air to ensure stable, efficient burning. A properly functioning burner is key to achieving the desired temperature and efficiency of the system.

How to Use the GB142 Parts Diagram Effectively

When working with heating systems, having a clear reference to the internal components is essential for efficient repairs and maintenance. Understanding how to use visual guides effectively can save time, prevent errors, and ensure that issues are diagnosed and resolved quickly.

Familiarize Yourself with the Layout

Before diving into repairs, take the time to familiarize yourself with the layout of the system. Understanding the placement of each component will help you identify potential problems more easily. Recognizing where key elements are located allows you to work more efficiently and avoid unnecessary disassembly of unrelated parts.

Follow the Visual Cues for Troubleshooting

Visual guides often provide helpful annotations and markings that can assist in troubleshooting specific issues. Pay attention to any labels or arrows indicating flow direction, temperature zones, or possible points of failure. These cues can help you focus on the most likely causes of malfunctions, speeding up the diagnostic process.