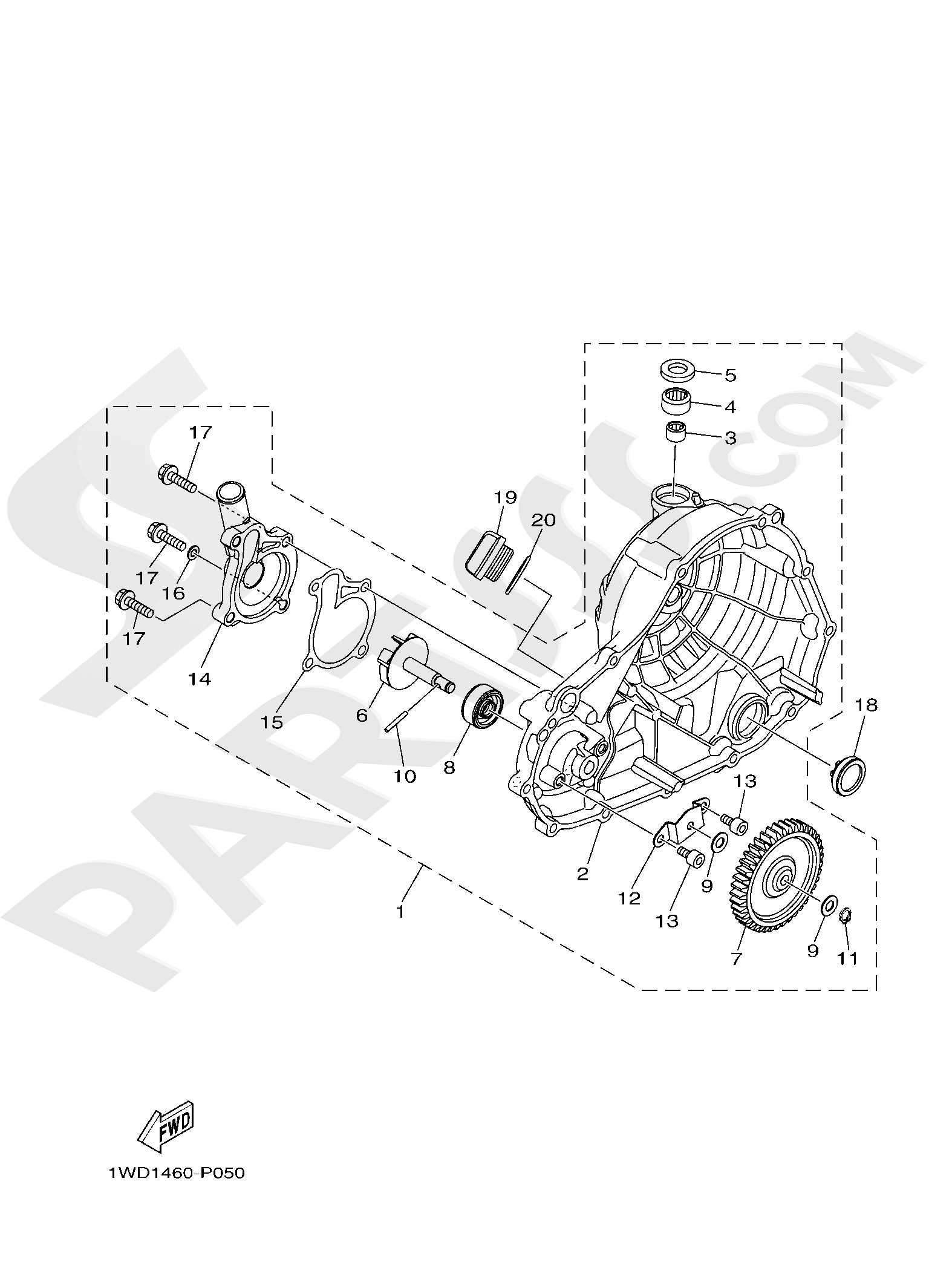

Understanding the various elements that make up a complex machine is crucial for both maintenance and repair. A well-organized schematic can provide a clear representation of how each piece fits together and operates. This guide offers insights into interpreting such schematics for efficient use and troubleshooting.

By examining the different sections of the layout, users can identify the role and function of each individual component. Knowing this allows for a more informed approach to repairs, ensuring minimal downtime and prolonging the lifespan of the machinery.

Proper knowledge of the assembly is essential for anyone involved in operating or servicing this equipment. Whether you’re a seasoned professional or a newcomer, the ability to decode the system’s structure will enhance your overall understanding and performance.

Understanding the Equipment Components

Every complex tool or machine is made up of several interconnected elements that work together to ensure its functionality. A detailed view of these individual components is essential for anyone who works with or maintains such equipment. Understanding the role of each part helps in diagnosing issues, performing regular maintenance, and making informed decisions about repairs.

Each component in the assembly serves a specific function, contributing to the overall performance and efficiency of the machine. Familiarity with these parts allows operators to quickly identify potential problems, address malfunctions, and carry out repairs with precision, reducing downtime.

Learning how to identify and understand the different components also aids in proper usage, ensuring that each element operates within its intended parameters. This knowledge is vital for both maximizing the machine’s lifespan and maintaining safety standards during operation.

Key Parts and Their Functions in Detail

In any sophisticated machine, each individual component is crucial for the tool’s overall functionality. These essential elements work in tandem to ensure optimal performance, and each part is designed for a specific purpose within the system. Understanding these components and their roles helps users maintain efficiency and prevent operational issues.

The core elements typically include power mechanisms, safety features, and control systems. The power mechanism drives the equipment’s main functions, while the safety features ensure secure operation, preventing accidents. Control systems, on the other hand, allow users to regulate and direct the machine’s actions with precision.

Each of these components plays an integral role, and even minor damage to a single part can disrupt the entire machine’s function. Having a thorough understanding of their purposes ensures that operators can effectively troubleshoot problems and perform necessary maintenance tasks with confidence.

How to Interpret the Equipment Layout

Understanding a schematic representation of a machine’s internal structure is vital for troubleshooting and repairs. A well-designed layout serves as a visual guide to help operators locate and understand each component’s position and function. Knowing how to read this information properly is key to maintaining the system’s performance and efficiency.

Reading the Layout Symbols

Every schematic uses symbols to represent different components and their connections. Familiarizing yourself with these symbols is the first step in decoding the layout. Each symbol corresponds to a specific part, and understanding these representations allows you to quickly pinpoint areas that require attention or maintenance.

Following the Flow of the System

Once the symbols are understood, it is important to follow the flow of the system. This involves identifying how the components interact and how power, signals, or other vital elements travel through the system. By tracking this flow, operators can easily locate potential issues and understand the sequence of operations within the machine.