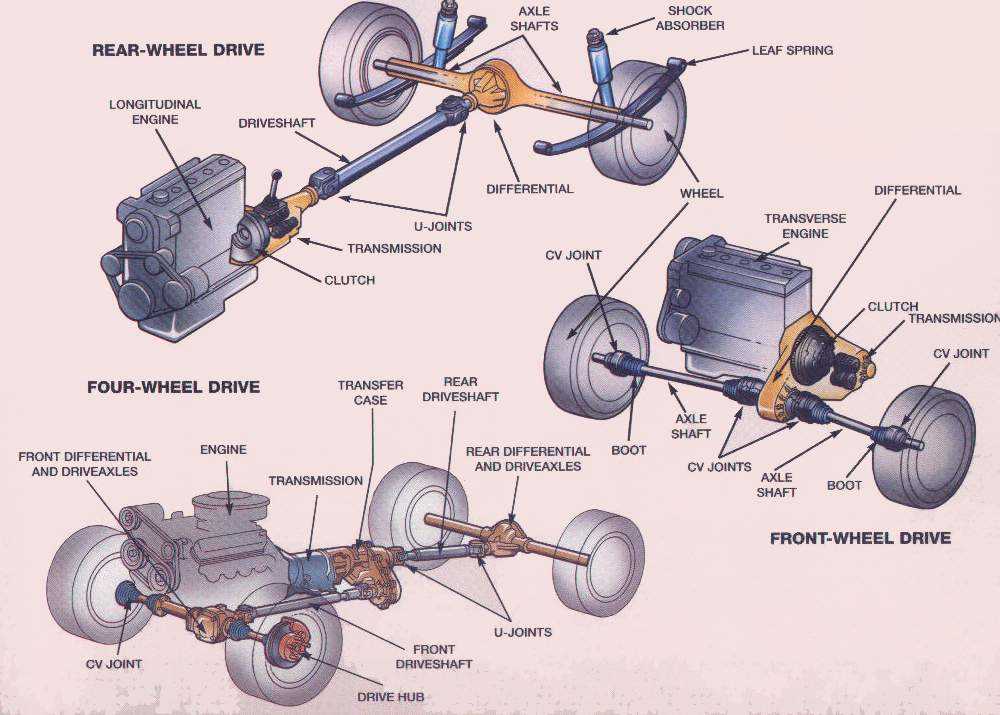

In any vehicle, the components responsible for transmitting power from the engine to the wheels are crucial for smooth operation. These elements are designed to work together, ensuring efficient performance and mobility. Understanding how these parts interact is essential for proper maintenance and troubleshooting.

Each vehicle’s drive system contains intricate mechanisms that allow movement, flexibility, and control. These systems are often composed of several interconnected pieces that must function in harmony. A comprehensive understanding of their layout can help diagnose issues and prevent unnecessary repairs.

By exploring the design of these systems, we can gain insights into how individual components contribute to overall performance. This knowledge is especially valuable for anyone seeking to maintain, repair, or upgrade their vehicle with precision.

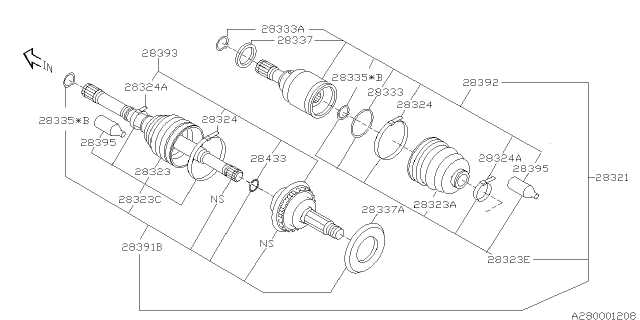

Key Components of a CV Axle

To fully comprehend how the drive system functions, it’s important to look at the key elements that make up this mechanism. These components are essential for ensuring smooth power transfer from the engine to the wheels, enabling motion and stability.

Each element plays a unique role, working together to maintain balance and performance. The most vital parts include:

- Joint Boots: These flexible covers protect internal joints from dirt, debris, and moisture, preventing damage and wear over time.

- Inner Joint: Responsible for accommodating the rotational movement and allowing the driveshaft to pivot while the vehicle turns or moves up and down.

- Outer Joint: Located at the wheel side, this component helps transmit rotational force while allowing the suspension to move freely and accommodate steering angles.

- Drive Shaft: The main shaft that transmits torque from the engine to the wheels, providing the power needed to move the vehicle.

Each of these components must function together seamlessly. When one part fails, it can lead to a cascade of issues affecting the vehicle’s handling, power delivery, or overall performance. Regular maintenance and inspection of these key elements are essential for long-term reliability.

How to Read a CV Axle Diagram

Interpreting technical illustrations of vehicle drive systems can be challenging without a basic understanding of their structure. These visuals often contain detailed representations of the internal components and their relationships to each other, helping technicians diagnose issues and plan repairs. Knowing how to read these visuals is essential for anyone working with drivetrains or performing vehicle maintenance.

Understanding the Symbols

Most technical schematics use standardized symbols to represent different parts. Arrows typically indicate movement or force direction, while lines often represent connections between components. Recognizing these symbols can significantly speed up the interpretation process, allowing you to understand how force is transmitted or where potential weaknesses may lie.

Identifying Key Elements

Another crucial step in reading a technical drawing is identifying the key elements in the system. Components like protective covers, joints, and shafts are typically labeled for easy identification. Once the major components are pinpointed, understanding their function in the broader context becomes much easier.

By breaking down each section of the diagram, it becomes possible to visualize the overall functionality and pinpoint areas that may need attention. With experience, reading these illustrations will become an intuitive process, helping you maintain or repair the system more efficiently.

Common Issues with CV Axle Parts

Drive systems are essential for proper vehicle movement, but like any mechanical components, they are prone to wear and tear. Over time, certain elements within the drivetrain can experience failure, leading to reduced performance or even complete breakdowns. Identifying common issues early can save both time and money, allowing for timely repairs.

Wear and Tear on Joints

One of the most common problems involves the joints within the drive system. Due to constant movement and stress, these joints can degrade over time. When they begin to fail, you may notice clicking sounds or vibrations while turning or accelerating. Ignoring these signs can lead to more severe damage, potentially causing a loss of control over the vehicle.

Damaged Protective Boots

The protective boots that cover the joints are also vulnerable to damage. When cracked or torn, debris and moisture can enter the internal components, accelerating wear. This can lead to premature failure of the joints, causing costly repairs. Regular inspections of these boots are necessary to ensure they remain intact and functional.

Other issues may include imbalanced shafts or improper alignment, which can cause uneven wear and poor handling. Regular maintenance, including inspecting these components for damage and replacing worn-out parts, is key to extending the lifespan of the drivetrain and ensuring smooth operation.