When maintaining or repairing any power tool, understanding its internal structure is essential. This knowledge helps ensure that each part functions optimally and can be replaced or fixed when necessary. For those looking to service their equipment effectively, having a clear visual reference of all its components is invaluable.

In this guide, we will explore the essential parts that make up your chainsaw, along with how they work together to provide the performance you need. Whether you are a seasoned technician or a DIY enthusiast, having an organized breakdown of these key components will make the repair and maintenance process much smoother.

Proper maintenance can extend the life of your tool, while preventing costly repairs down the line. We’ll walk you through a comprehensive view of how to approach each part, ensuring your equipment stays in top shape for years to come.

Understanding Chainsaw Components

To effectively maintain and repair any power tool, it’s crucial to grasp the role of each internal element. Every component plays a specific function, working together to ensure smooth operation. Understanding these parts can help users identify potential issues, perform routine maintenance, and extend the lifespan of the tool.

Key Elements and Their Functions

The main components of a chainsaw include the engine, fuel system, cutting mechanism, and safety features. The engine powers the entire unit, while the fuel system ensures the right mix of gasoline and oil for optimal performance. The cutting mechanism consists of the chain, bar, and sprocket, all of which work in unison to deliver efficient cutting action. Additionally, safety elements like the brake and throttle are designed to prevent accidents during operation.

Importance of Regular Inspection

Regularly checking each of these components is vital to maintaining the efficiency of your tool. Inspecting the engine for wear, cleaning the air filter, and lubricating the chain are simple yet effective tasks that can significantly enhance performance. By familiarizing yourself with the function of each part, you can detect early signs of wear or malfunction, saving time and money on repairs.

How to Use the Parts Breakdown

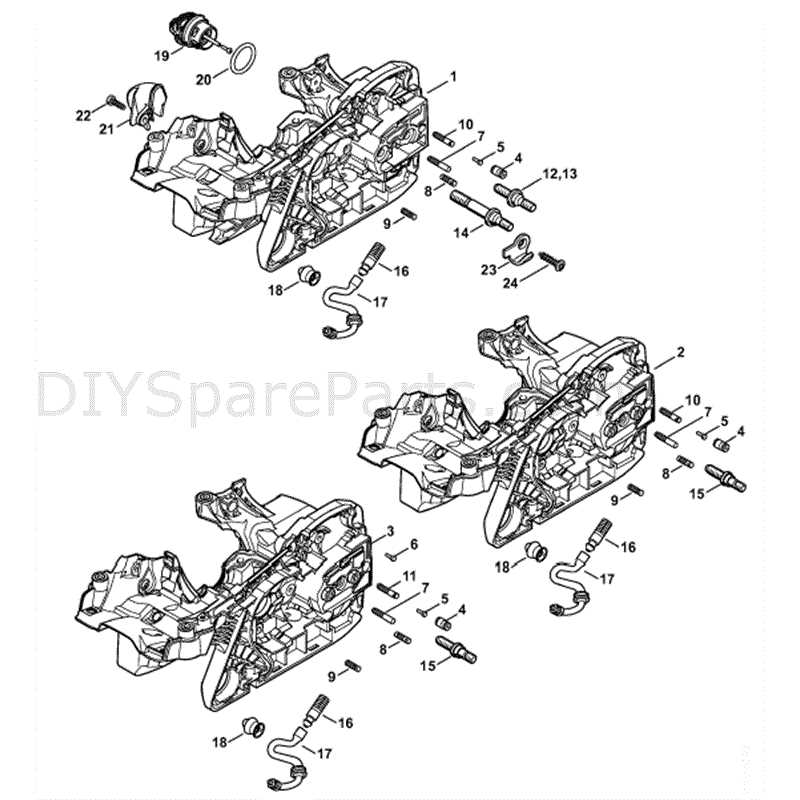

A visual breakdown of your tool’s components can be an invaluable resource when performing maintenance or repairs. This guide helps you understand how to identify and locate specific elements, making the repair process more efficient and less daunting. By following a structured diagram, you can easily pinpoint each part and understand its role within the system.

Identifying Components

The first step in utilizing the diagram is identifying each component. Each part is clearly marked with labels and numbers, corresponding to its placement within the tool. This ensures that you can easily match the part with the correct location, whether you’re replacing a worn-out item or checking for wear and tear.

Guided Maintenance and Repairs

Once you are familiar with the layout, the next step is using this breakdown to guide your maintenance tasks. Whether you need to clean the air filter, adjust the chain, or replace a specific part, the breakdown helps you follow a logical, step-by-step approach. Accurate identification ensures you are handling the right part at the right time, minimizing the risk of errors and unnecessary disassembly.

Common Chainsaw Maintenance Tips

Maintaining your power tool regularly is essential for ensuring optimal performance and extending its lifespan. Simple care practices can prevent major breakdowns and keep the equipment running smoothly throughout the season. With the right approach, you can keep your tool in peak condition, avoiding costly repairs and downtime.

Regular Lubrication and Chain Tension

One of the most important maintenance tasks is keeping the chain properly lubricated. A well-lubricated chain moves smoothly and reduces wear on both the chain and the bar. Additionally, checking the tension of the chain is crucial. If it’s too loose, it can slip off during use, while a chain that is too tight can cause strain on the engine. Regularly adjust the tension and apply chain oil to ensure smooth operation.

Air Filter Cleaning and Engine Care

Over time, the air filter collects debris, which can block airflow and cause the engine to overheat or perform inefficiently. Cleaning or replacing the filter regularly helps maintain engine performance. Additionally, keep an eye on the spark plug and fuel lines. Replacing the spark plug once a season and inspecting the fuel system can prevent starting issues and ensure a reliable operation every time you use your tool.